Supercooled water type dynamic ice slurry making system and ice making method

A dynamic ice slurry and cold water technology, applied in ice making, air conditioning system, ice making, etc., can solve the problems of large loss of cooling capacity, weakening of energy-saving advantages of supercooled water dynamic ice slurry production technology, and achieve preheating loss Reduction, significant energy saving benefits, and the effect of reducing the loss of preheating cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

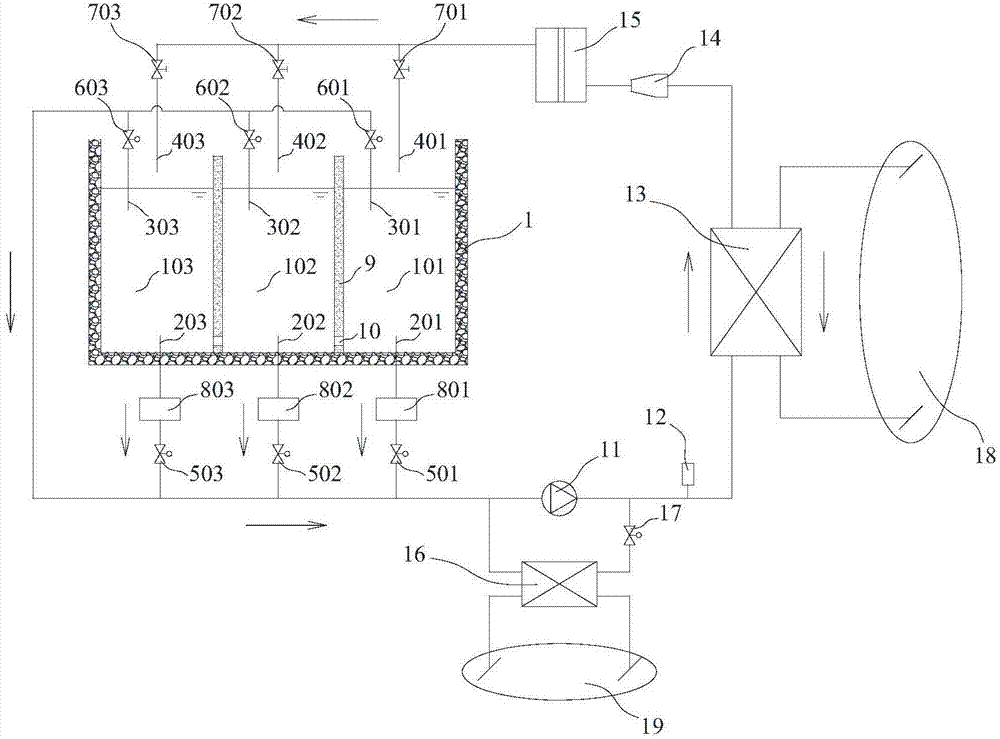

[0024] Such as figure 1As shown, the ice storage tank 1 is equally divided into three sub-tanks with equal volumes by the partition plate 9 , that is, the first sub-tank 101 , the second sub-tank 102 and the third sub-tank 103 . A first upper water intake pipe 301 and a first ice slurry pipe 401 are arranged above the first sub-tank 101 , and a first lower water intake pipe 201 is arranged below the first sub-tank 101 . A second upper water intake pipe 302 and a second ice slurry pipe 402 are arranged above the second sub-tank 102 , and a second lower water intake pipe 202 is arranged below the second sub-tank 102 . A third upper water intake pipe 303 and a third ice slurry pipe 403 are arranged above the third sub-tank 103 , and a third lower water intake pipe 203 is arranged below the third sub-tank 103 . The first, second and third lower water intake pipes are respectively provided with a first lower regulating valve 501 , a second lower regulating valve 502 and a third lo...

Embodiment 2

[0036]The above-mentioned embodiment 1 of the present invention is the situation that the ice storage tank is divided into three equal parts. In Embodiment 2, the ice storage tank can be equally divided into 2 sub-tanks or other number of sub-tanks equal to 2 or more. In other embodiments, step 1: arbitrarily select the Nth sub-tank and the Mth sub-tank, the N and the M are any different positive integers, select the Nth sub-tank for ice making, and use the Mth sub-tank The hot water in the sub-tank is heated and decrystallized, the lower regulating valve on the lower water intake pipe of the N sub-tank is opened, and the on-off valve on the ice slurry pipe is opened, and the lower regulating valve of the N sub-tank can be kept Adjust the state of the opening, keep the upper regulating valve of the Mth sub-slot in a state where the opening can be adjusted, and close all other valves; make the water flow from the Nth sub-slot through the cold water heat exchanger and the crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com