Complex inoculant and application thereof in degrading cellulose in poultry and livestock manure

A technology of compound inoculants and strains, applied in application, bacteria, fungi and other directions, can solve the problems of low cellulose degradation efficiency, low enzyme production efficiency of fermentation inoculants, and no enzyme production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

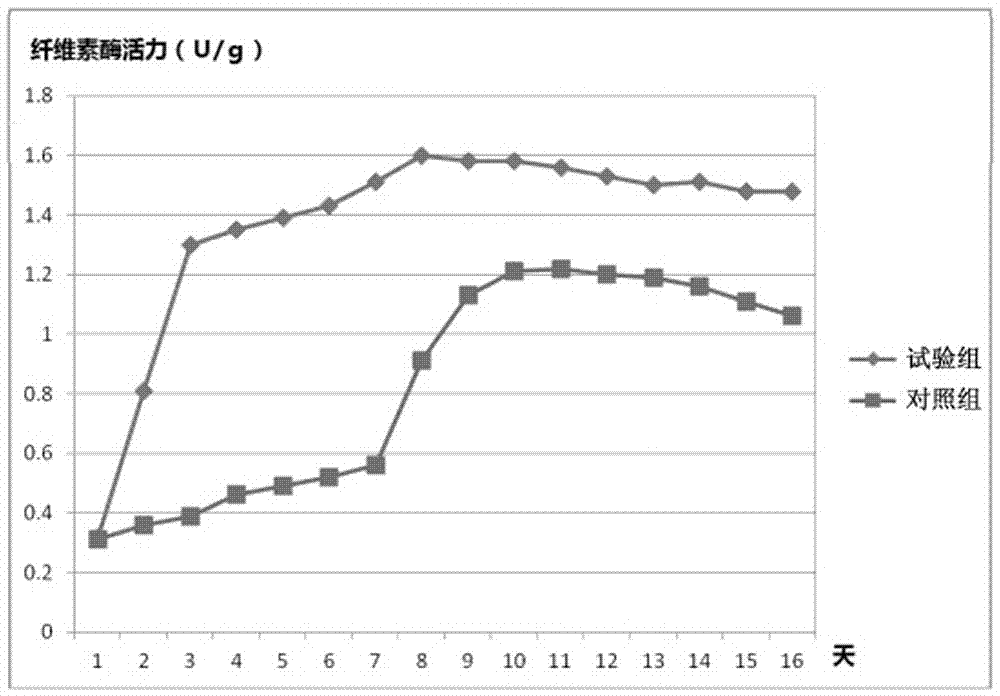

Image

Examples

Embodiment Construction

[0028] 1. Test group

[0029] Material preparation

[0030] Take 600kg of poultry manure from the farm, its organic matter content is 79%, C / N (carbon-to-nitrogen ratio) is 16, water content is 65%, and pH value is 7.21.

[0031] Take the purchased Trichoderma reesei, Pseudomonas, Candida parapsilosis, Bacillus subtilis subsp. Bacillus liquefaction was cultured in beef extract peptone medium for 60-72 hours, until the concentration reached 10 8 / ml, the culture temperature is 28°C; Among them, Trichoderma reesei, Candida parapsilosis, and Aspergillus fumigatus were cultured in PDA medium for 96 hours, until the number of effective viable bacteria reached about 104 CFU / g, and the culture temperature was 26 ℃.

[0032] Use 30kg of rice husk powder to adjust the moisture content of 600kg of poultry manure to 50%-55%, and pile them in a fermentation box of 2m*1m*0.5m. According to the volume ratio of 1.5:1.5:1:1:1:1, take adjusted concentrations of Trichoderma reesei, Pseudomo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com