Method for removing quinolone micropollutants in residual activated sludge

A residual activity, quinolone technology, applied in the field of removal of quinolone micro-pollutants, can solve the problem that the removal effect of quinolone micro-pollutants has not been studied, and achieves low equipment and material costs, excellent addition amount, and enhanced decomposition effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

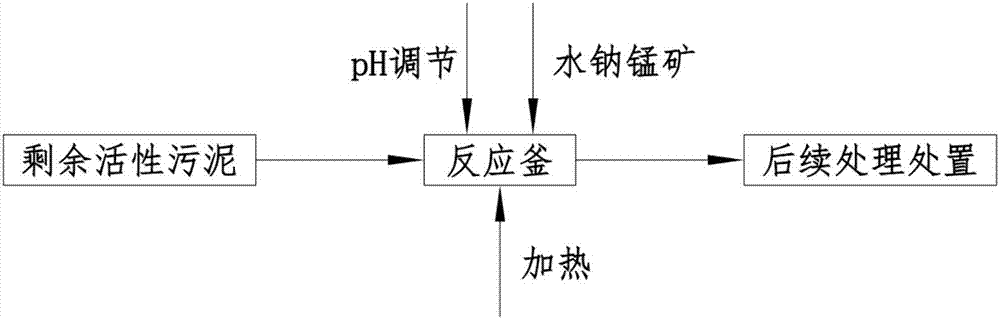

[0023] Embodiment one: if figure 1 As shown, a method for removing quinolone micro-pollutants in excess activated sludge, the concentration of quinolones micro-pollutants is 2276ng / g dry sludge, and the remaining activated sludge with a solid content of 0.5% is transported to the reactor, Regulate the pH of remaining activated sludge to be 7.0, then add granular birnessite in remaining activated sludge, in the mixture of remaining activated sludge and birnessite, the concentration of birnessite is 10mg / g dry sludge, Finally, stir evenly while heating to make the remaining activated sludge and birnessite undergo thermal hydrolysis reaction. The thermal hydrolysis temperature is controlled at 40°C. After reacting for 10 minutes, the concentration of quinolone micro-pollutants in the remaining activated sludge is measured to be 682ng / g dry sludge, in which the concentration of ciprofloxacin decreased from 889ng / g dry sludge to 228ng / g dry sludge, and the concentration of norflox...

Embodiment 2

[0024] Embodiment two: if figure 1 As shown, a method for removing quinolone micro-pollutants in excess activated sludge, the concentration of quinolones micro-pollutants is 1411ng / g dry sludge, and the remaining activated sludge with a solid content rate of 3.5% is transported to the reactor, Regulate the pH of remaining activated sludge to be 6.0, then add granular birnessite in remaining activated sludge, in the mixture of remaining activated sludge and birnessite, the concentration of birnessite is 30mg / g dry sludge, Finally, stir evenly while heating to make the remaining activated sludge and birnessite undergo thermal hydrolysis reaction. The thermal hydrolysis temperature is controlled at 50°C. After reacting for 30 minutes, the concentration of quinolone micro-pollutants in the remaining activated sludge is measured to be 318ng / g dry sludge, in which the concentration of ofloxacin decreased from 358ng / g dry sludge to 76ng / g dry sludge, and the concentration of norflox...

Embodiment 3

[0025] Embodiment three: as figure 1 As shown, a method for removing quinolone micro-pollutants in excess activated sludge, the concentration of quinolones micro-pollutants is 1869ng / g dry sludge, and the remaining activated sludge with a solid content rate of 7.7% is transported to the reactor, Regulate the pH of remaining activated sludge to be 4.0, then add granular birnessite in remaining activated sludge, in the mixture of remaining activated sludge and birnessite, the concentration of birnessite is 50mg / g dry sludge, Finally, stir evenly while heating to make the remaining activated sludge and birnessite undergo thermal hydrolysis reaction. The thermal hydrolysis temperature is controlled at 60°C. After reacting for 1 hour, the concentration of quinolone micro-pollutants in the remaining activated sludge is measured to be 261ng / g dry sludge, in which the concentration of ofloxacin decreased from 601ng / g dry sludge to 88ng / g dry sludge, and the concentration of ciproflox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com