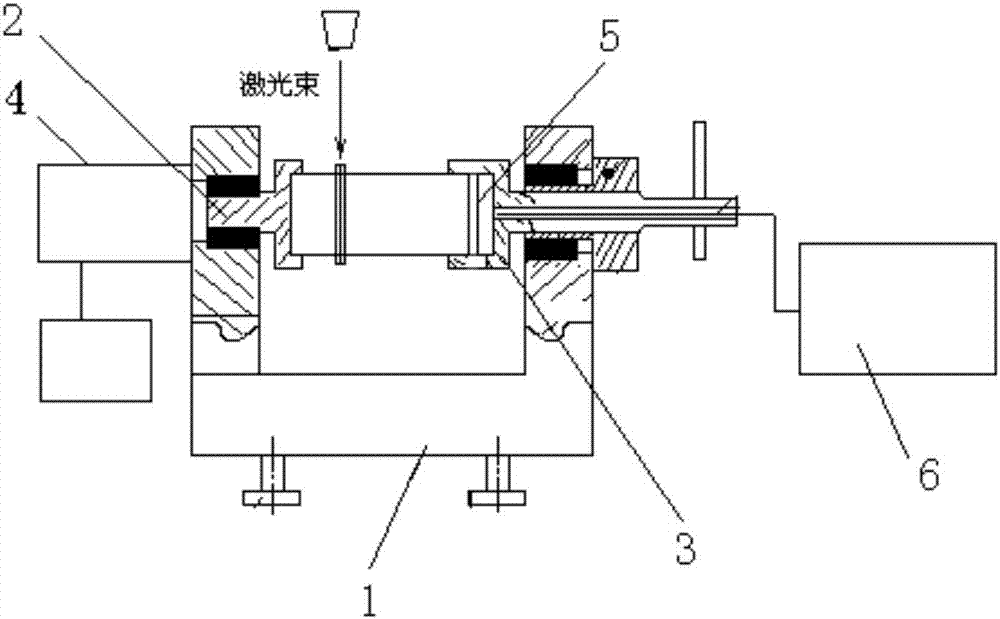

Ultrasonic assisted laser welding device and method for dissimilar metal materials

A dissimilar metal and laser welding technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as difficult to guarantee sealing performance, achieve the effect of improving sealing performance, increasing the first-time success rate, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

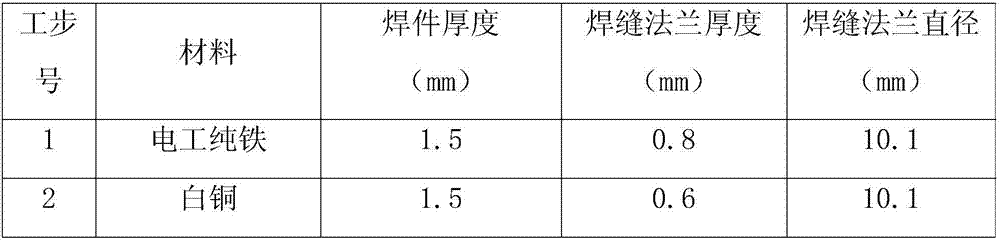

[0040] The following is the ultrasonic-assisted laser welding of the electrical pure iron and cupronickel specimens in Table 1, a total of 8 sets, of which 4 sets are added with ultrasonic excitation, and 4 sets are not added with ultrasonic excitation. The implementation process is described in detail, and the ultrasonic-assisted Comparative analysis of the leakage rate effect after welding of laser welding and pure laser welding test pieces:

[0041] Table 1: Main parameters of the weldment

[0042]

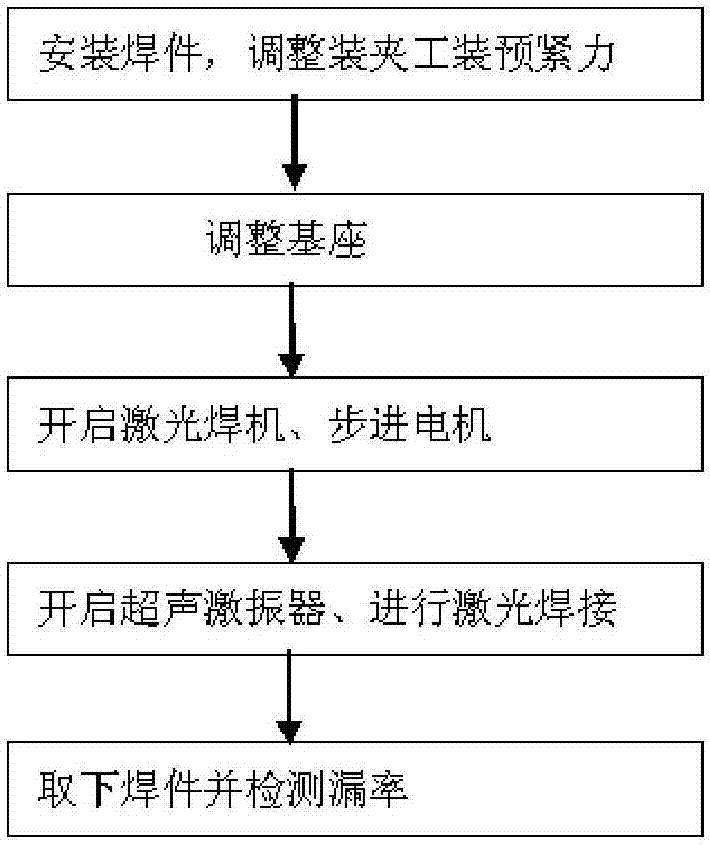

[0043] The implementation process of ultrasonic assisted laser welding is as follows:

[0044] (1) Install the dissimilar metal weldment between the first top tool and the second top tool, adjust the axial displacement of the second top tool, and clamp the dissimilar metal weldment;

[0045] (2) Adjust the base so that the laser head is aligned with the highest point of the welding seam of the dissimilar metal weldment, place it on the laser welding work platform, and adjust ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com