An integrated circulating fluidized bed equipment

A circulating fluidized bed and equipment technology, which is applied in the fields of gas-solid heat exchange, gas-solid phase catalytic reaction, and solid combustion reaction, can solve the problems of high equipment cost and operating cost, small operating flexibility, and complicated equipment, and reduce production and design cost, avoiding dead zone, and simplifying the effect of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

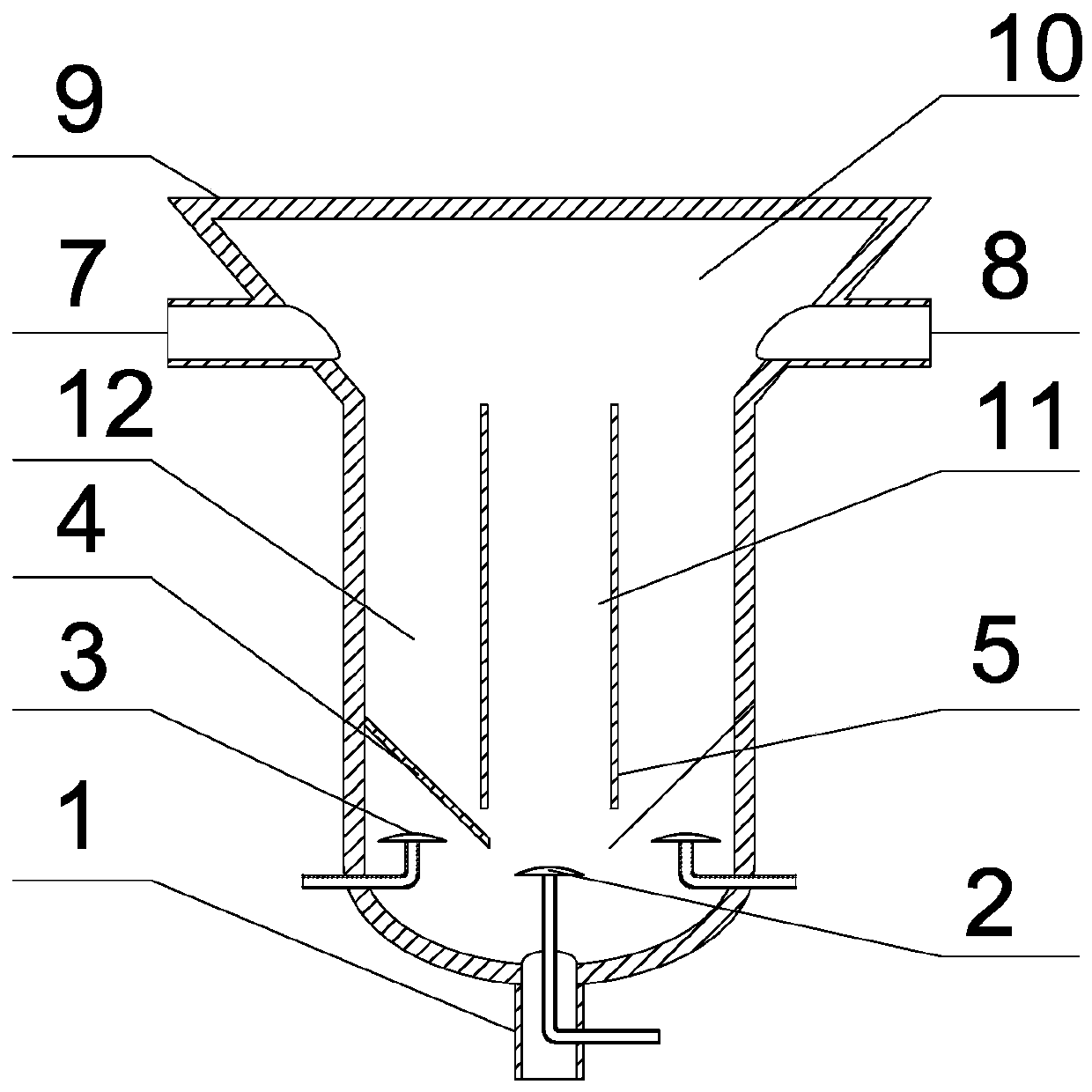

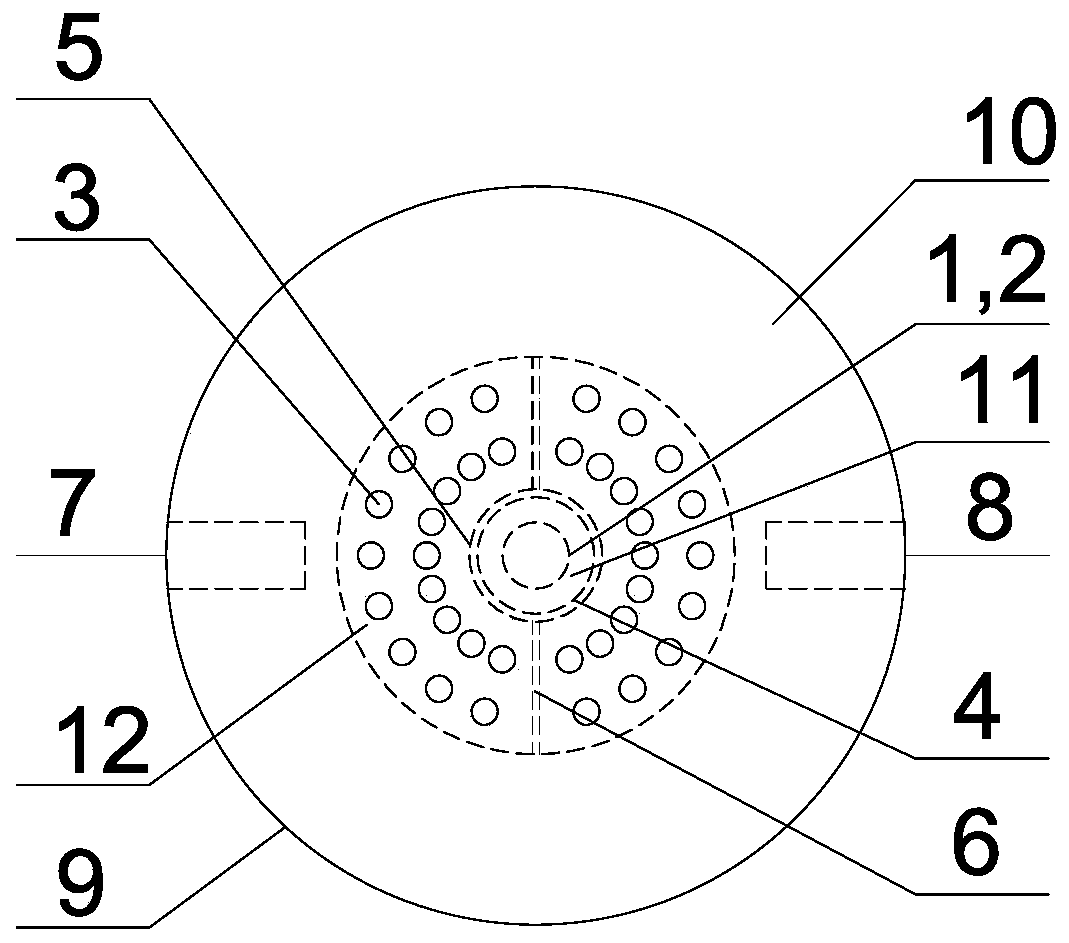

[0027] The patent of the present invention is further described in conjunction with the accompanying drawings:

[0028] Such as figure 1 , 2 Shown: an integrated circulating fluidized bed equipment, from bottom to top are solid collection port (1), central gas distributor (2), annular gas distributor (3), solid collector (4), inner Sleeve (5), gas outlet (7), solid inlet (8). The central gas distributor (2) is located directly under the inner sleeve (5), and the annular gas distributor (3) is located around the central gas distributor (2) and between the inner and outer sleeves.

[0029] The upper part of the outer sleeve (9) is a frustum-shaped structure with a thick upper part and a thinner lower part. The ratio of the maximum diameter to the minimum diameter is 2, and the bottom part is an equal-diameter cylinder, which is made by welding with the upper part. The diameter of the inner sleeve (5) accounts for 30% of the diameter of the lower part of the outer sleeve (9), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com