Multistage driving type material stirring mechanism

A stirring mechanism and driven technology, which is applied in the field of multi-stage driven material stirring mechanism, can solve the problems of insufficient material processing, affecting work efficiency, uneven stirring, etc., achieve high-speed, high-efficiency, high-stability solution stirring, improve production efficiency, The effect of improving homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

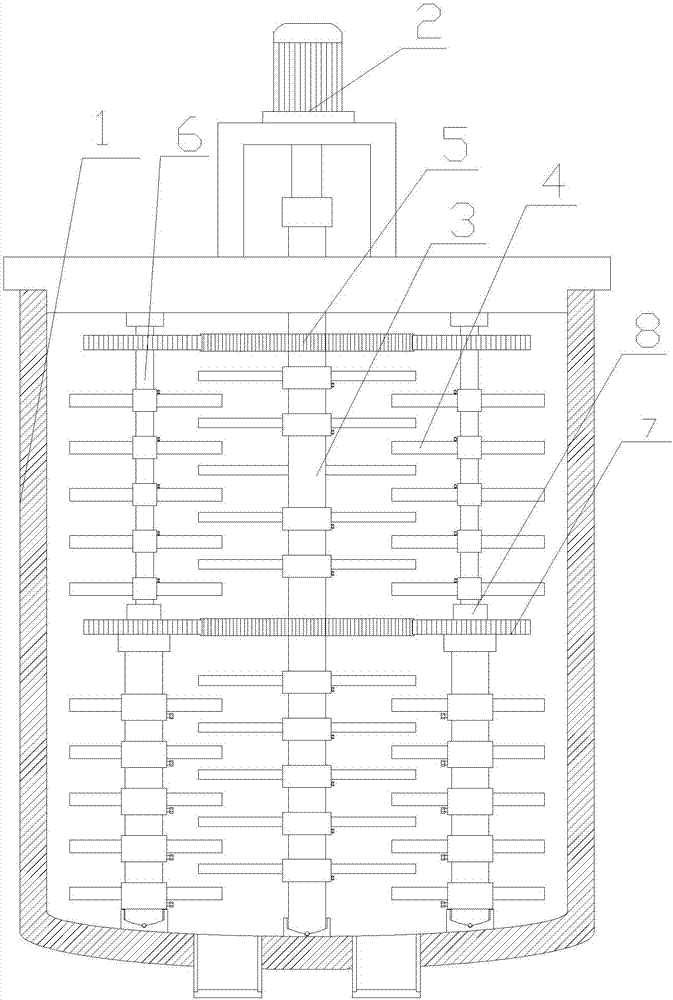

[0018] Such as figure 1 , figure 2 As shown, a multi-stage drive type material mixing mechanism, the main body includes a mixing tank 1, a driving motor 2 on the top of the mixing tank 1, a middle driving shaft 3 located inside the mixing tank 1, and a middle driving shaft 3 The upper mixing blade 4, the top of the middle drive shaft 3 passes through the mixing tank 1 and is connected to the drive motor 2 shaft, the middle drive shaft 3 is installed with a driving drive gear 5, and the two ends of the middle drive shaft 3 are installed with side drive shafts 6. A driven drive gear 7 is installed on the side drive shaft 6, the active drive gear 5 is toothed with the driven drive gear 7, and the side drive shaft 6 is installed with mixing blades 4 staggered with the middle drive shaft 3. , While the drive motor 2 drives the middle drive shaft 3 to stir, the active drive gear 5 on the middle drive shaft 3 drives the driven drive gear 7 on the side drive shaft 6 to drive the side d...

Embodiment 2

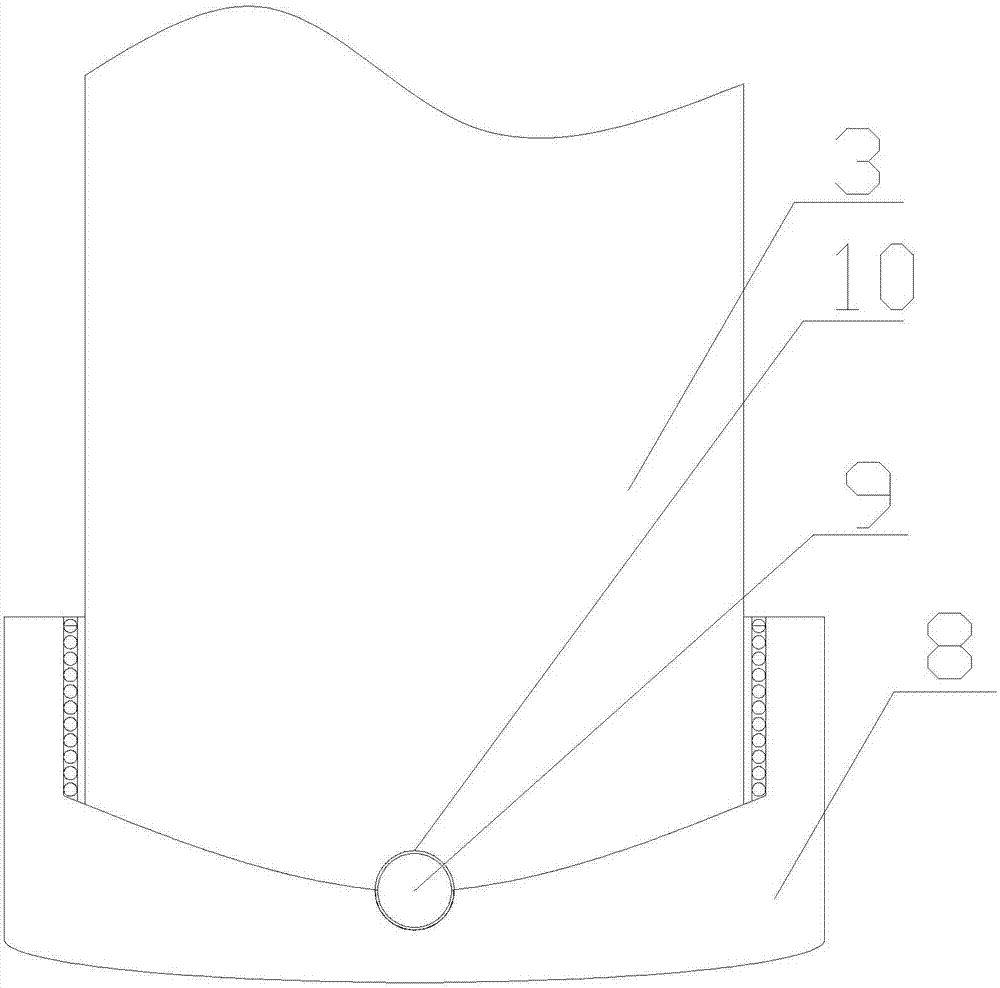

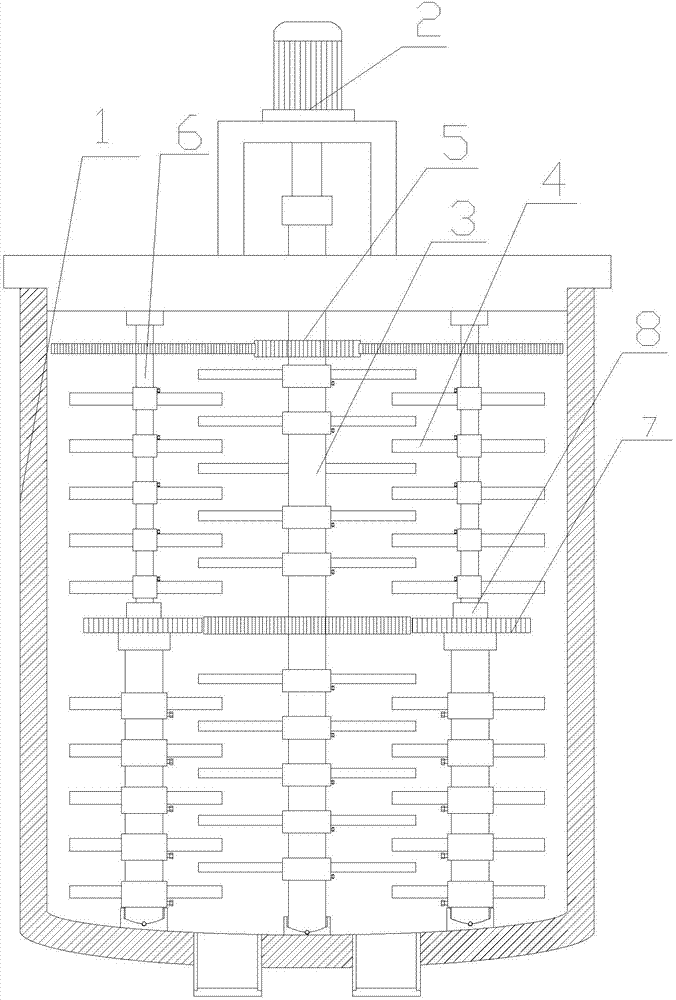

[0020] Such as figure 2 , image 3 As shown, a multi-stage drive type material mixing mechanism, the main body includes a mixing tank 1, a driving motor 2 on the top of the mixing tank 1, a middle driving shaft 3 located inside the mixing tank 1, and a middle driving shaft 3 The upper mixing blade 4, the top of the middle drive shaft 3 passes through the mixing tank 1 and is connected to the drive motor 2 shaft, the middle drive shaft 3 is installed with a driving drive gear 5, and the two ends of the middle drive shaft 3 are installed with side drive shafts 6. A driven drive gear 7 is installed on the side drive shaft 6, the active drive gear 5 is toothed with the driven drive gear 7, and the side drive shaft 6 is installed with mixing blades 4 staggered with the middle drive shaft 3. , While the drive motor 2 drives the middle drive shaft 3 to stir, the active drive gear 5 on the middle drive shaft 3 drives the driven drive gear 7 on the side drive shaft 6 to drive the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com