A steam-water separator component exhaust structure specially used for nuclear power plant steam generators

A steam-water separator and steam generator technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of insufficient steam exhaust pipes and insufficient steam exhaust capacity to meet the requirements, and save steam. The space of the cylinder on the generator can meet the demand of exhaust steam and ensure the effect of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

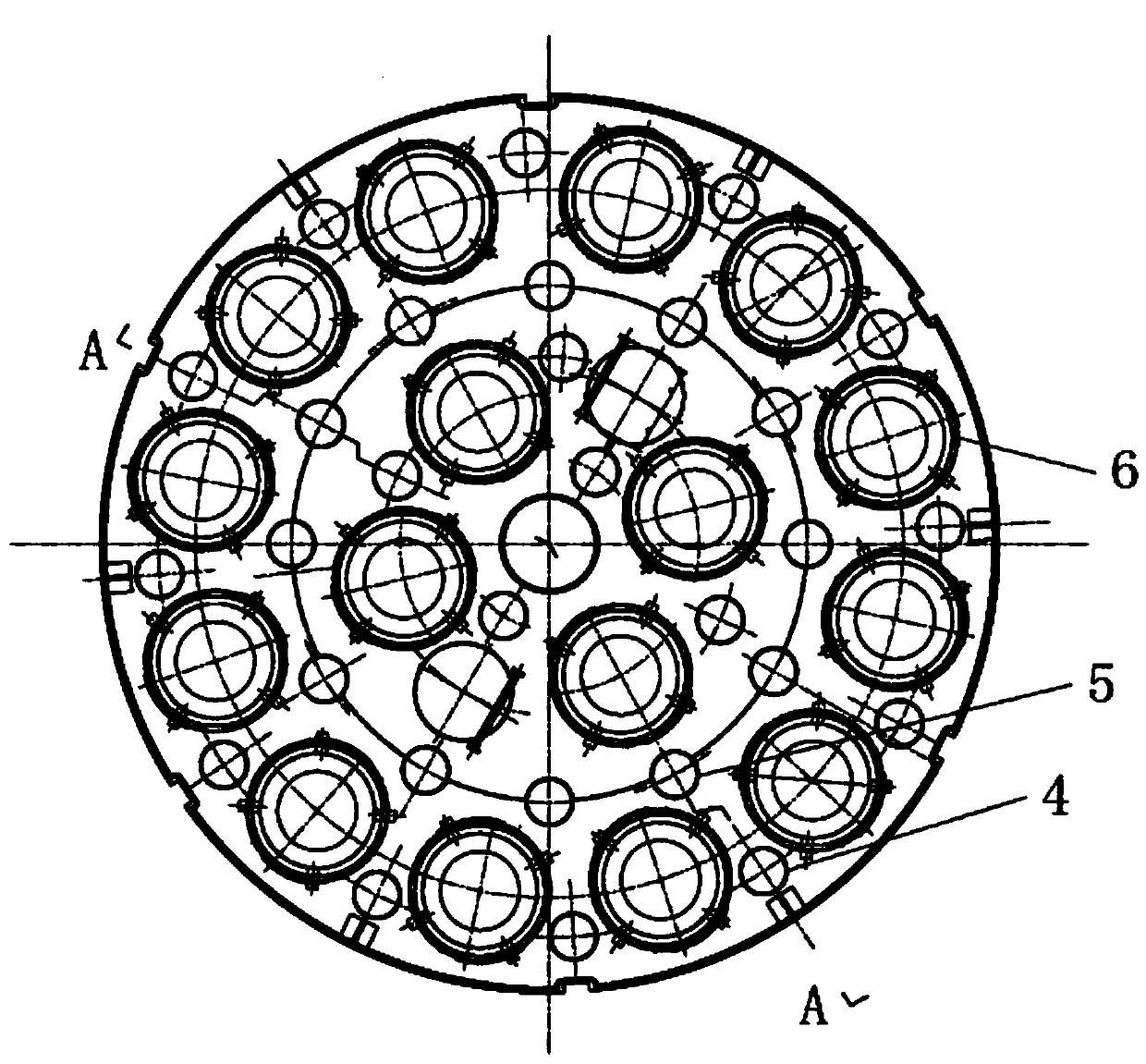

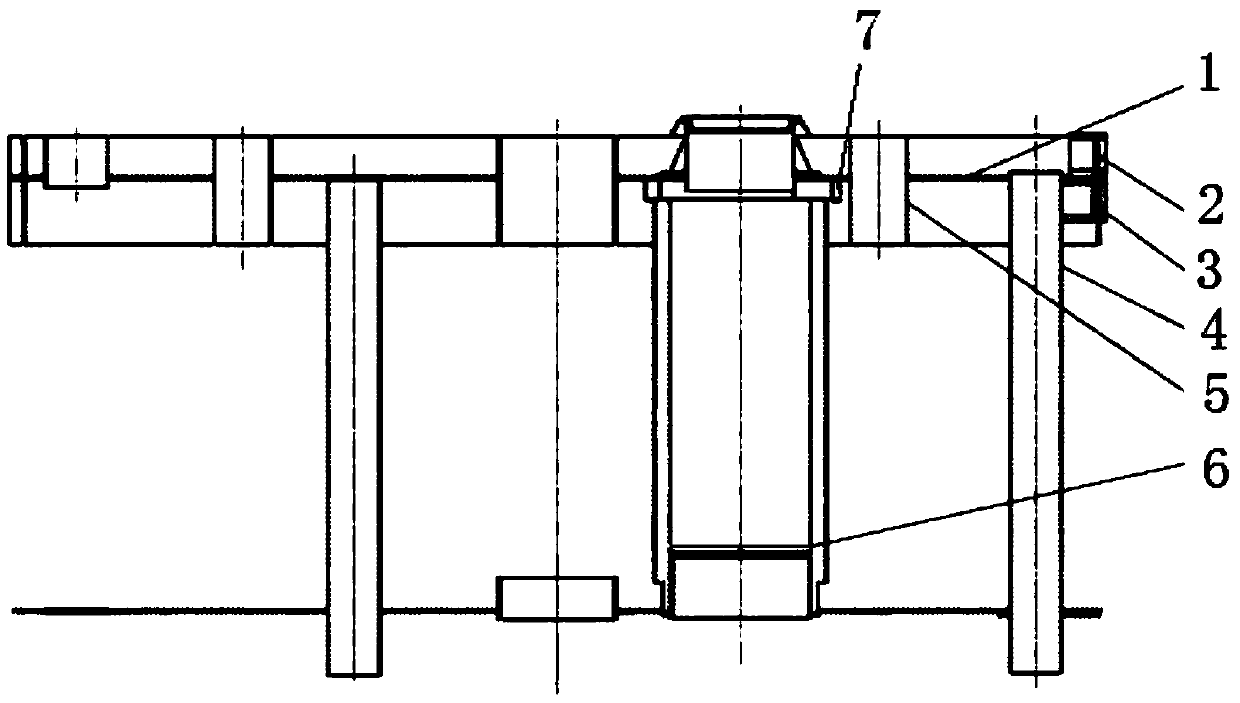

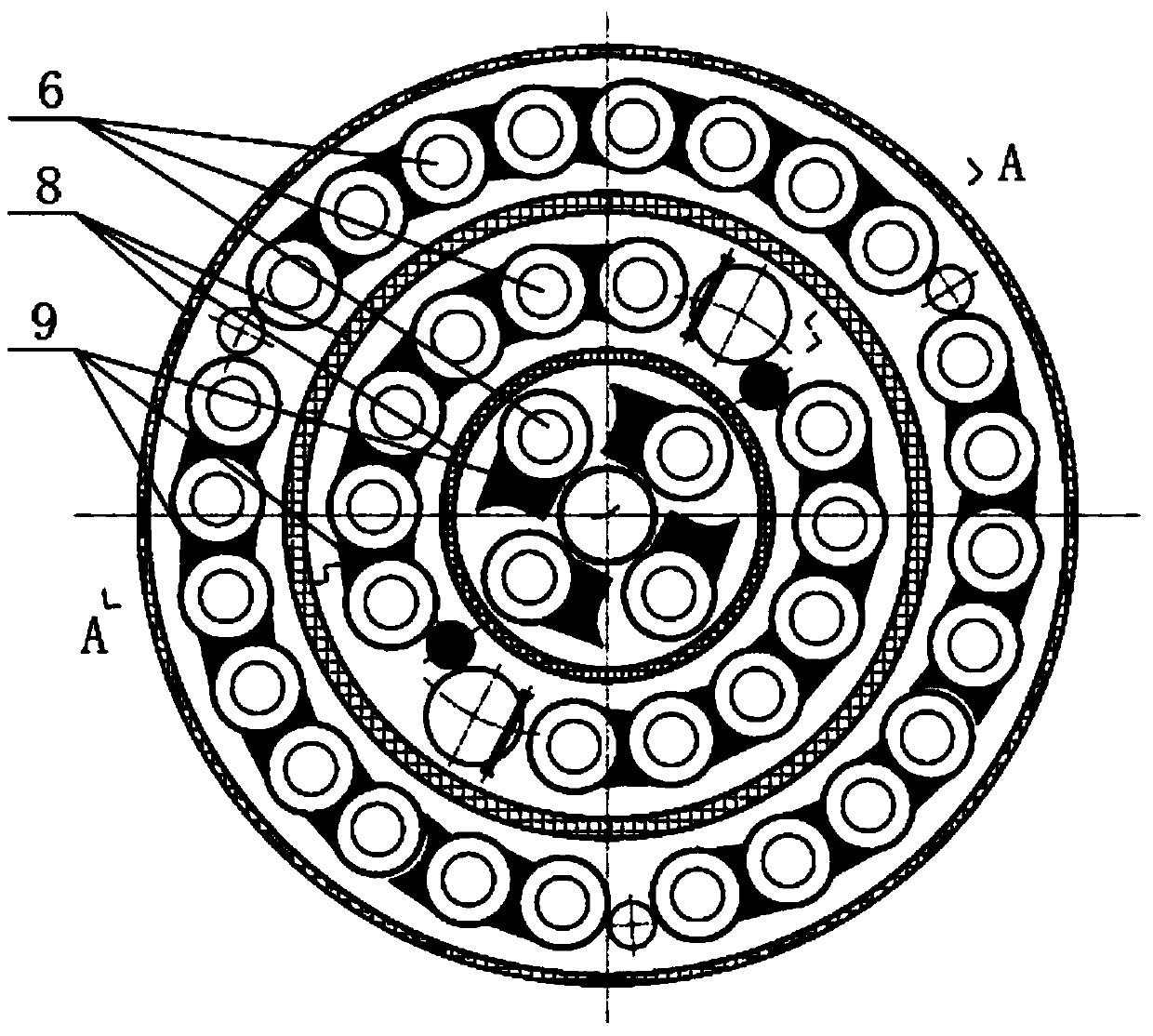

[0023] This embodiment is used to solve the hydrophobic problem. attached figure 1 And attached figure 2 It is a gravity-separated hydrophobic structure widely used in steam generators of existing nuclear power plants, and it mainly includes an upper deck 1 , an upper water-retaining coaming 2 , a lower water-retaining coaming 3 , a drain pipe 4 and an exhaust pipe 5 . The water collecting pan is formed around the upper water retaining coaming 2 and the upper deck 1 to collect the large-sized water droplets from the outlet of the steam-water separator and fall after being separated by gravity, and then flow into the water space of the upper cylinder of the steam generator through the drain pipe 4 , the function of the lower water retaining board 3 is to block the water flowing out from the steam-water separator, and act as a guide to make the water flow down gently along the water retaining board under the action of gravity. The steam also acts as a guide, so that the steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com