Method for preparing fish feed from vinasse

A technology for fish feed and distiller's grains, applied in animal feed, animal feed, climate change adaptation, etc., can solve the problems of unavailability of distiller's grains, environmental pollution, and many production personnel, so as to reduce investment in civil engineering and equipment, reduce production costs, and simplify Effects of machining programs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

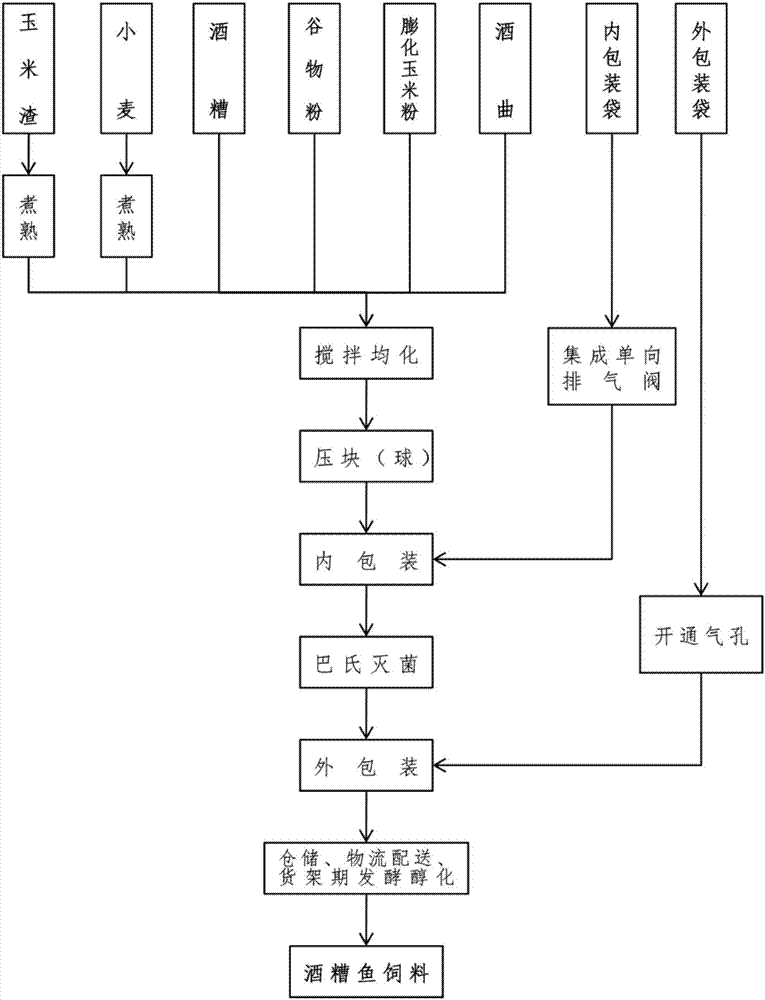

Image

Examples

Embodiment 1

[0042] A liquor company uses the naturally drained distiller's grains produced by itself as the main raw material, with a moisture content of 48% to 50%. Cook corn dregs and wheat separately; distiller's grains with distiller's grains, cooked corn dregs, cooked wheat, grain flour, puffed corn flour, distiller's yeast according to the quality of 1:0.08:0.15:0.1:0.1:0.007 After mixing, it is pressed into a block shape of 250mm × width 150mm × thickness 30mm to become distiller’s grain fish feed blank. A one-way exhaust valve with an opening pressure of 2-8mbar and a closing pressure of less than or equal to 2mbar is integrated on the plastic inner packaging bag, and the integration is bonded, and a vent hole with a diameter of 6mm is opened in the plastic outer packaging bag. Put a distiller's grain fish feed blank into an inner packaging bag with a one-way exhaust valve, seal it with a vacuum packaging machine, pasteurize it at 70°C for 50 minutes, then pack and seal the outer ...

Embodiment 2

[0047] A feed company uses undried distiller's grains in the natural state of a nearby distillery as the main raw material. After loading, unloading and transportation, the moisture content after arriving at the factory is 40% to 45%. Cook corn dregs and wheat separately; distiller's grains with distiller's grains, cooked corn dregs, cooked wheat, grain flour, puffed corn flour, distiller's yeast according to the quality of 1: 0.1: 0.05: 0.05: 0.1: 0.008 After mixing, it is pressed into a block shape of 150 mm wide by 100 mm wide by 28 mm thick to become distiller's grain fish feed blank. A one-way exhaust valve with an opening pressure of 2-8mbar and a closing pressure of less than or equal to 2mbar is integrated on the plastic inner packaging bag, and the integration is bonded, and a vent hole with a diameter of 4mm is opened in the plastic outer packaging bag. Put a distiller's grain fish feed blank into an inner packaging bag with a one-way exhaust valve, seal it with a va...

Embodiment 3

[0050] A fish feed company boiled corn dregs and wheat separately; mixed the cooked corn dregs with cooked wheat, grain flour, puffed corn flour, and distiller's yeast at a mass ratio of 1:1:0.15:0.1:0.012 and pressed them Grow 150mm x width 100mm x thickness 28mm blocks to become corn and wheat feed blanks. A one-way exhaust valve with an opening pressure of 2-8mbar and a closing pressure of less than or equal to 2mbar is integrated on the plastic inner packaging bag, and the integration is bonded, and a vent hole with a diameter of 4mm is opened in the plastic outer packaging bag. Put a piece of corn and wheat fish feed blank into an inner packaging bag with a one-way exhaust valve, heat seal it with a vacuum packaging machine, pasteurize it at 70°C for 40 minutes, then seal the outer packaging bag, and store it. Logistics distribution and shelf life After 1 month of fermentation and alcoholization, corn and wheat fermented fish feed is produced, which is specially used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com