Automatic latex draining device and automatic latex draining method

An automatic rubber discharge and rubber discharge technology, which is applied in agriculture, forestry, application, etc., can solve the problems of large technical training costs, increased labor costs, and decreased rubber tapping quality, so as to ensure long-term benefits, save labor costs, and reduce the difficulty of rubber mining. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

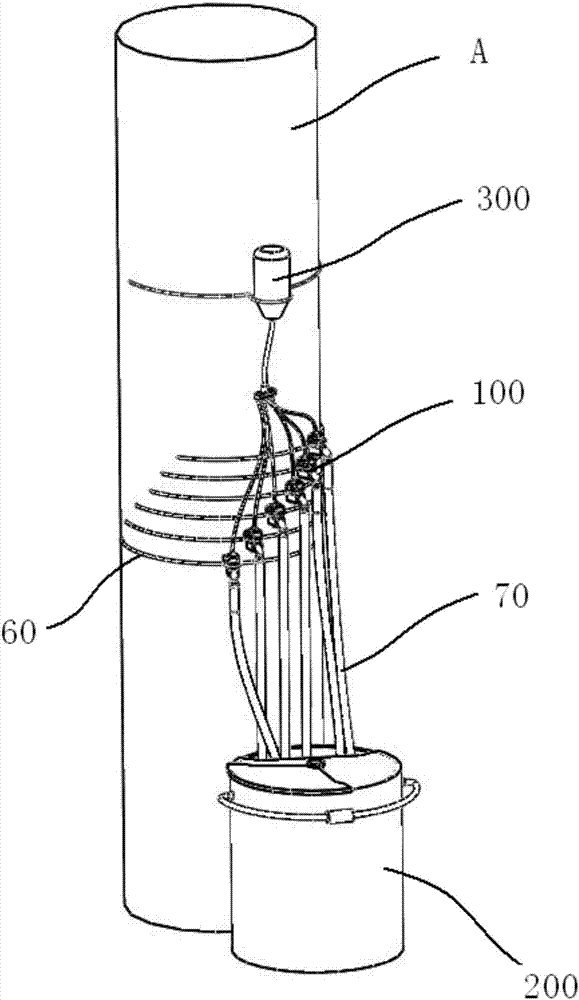

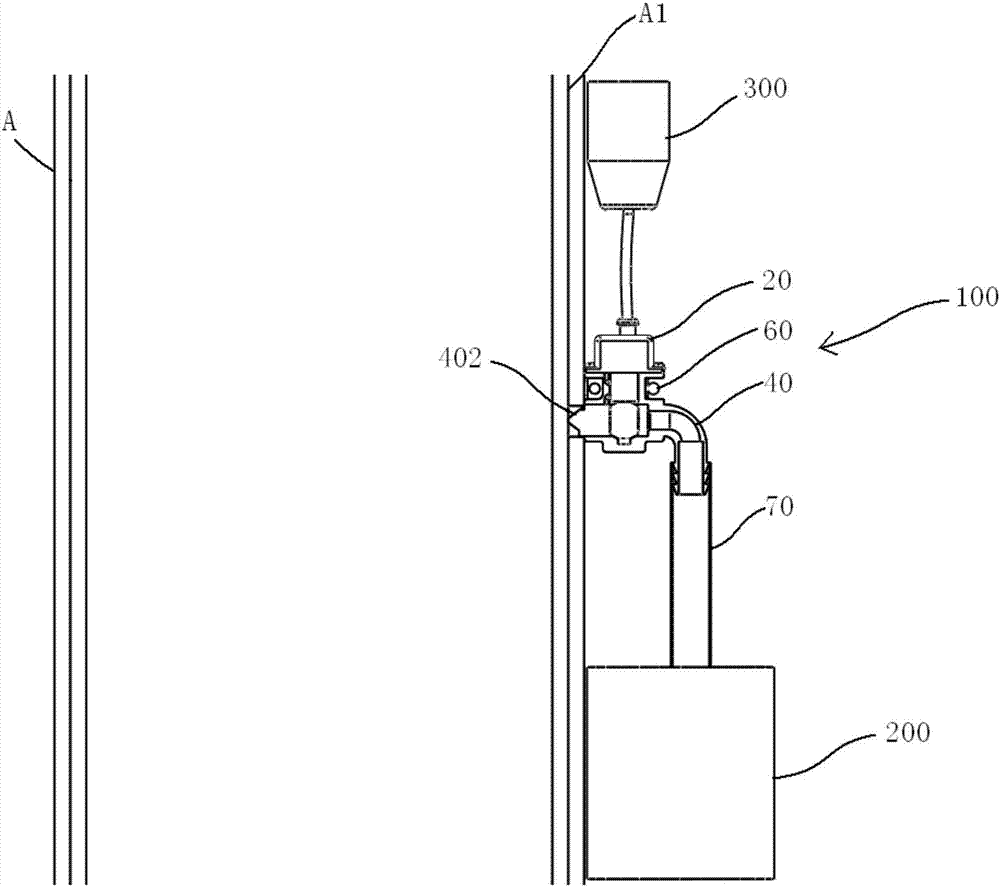

[0045] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the automatic glue removal device provided by the present invention; figure 2 for figure 1 Vertical section view.

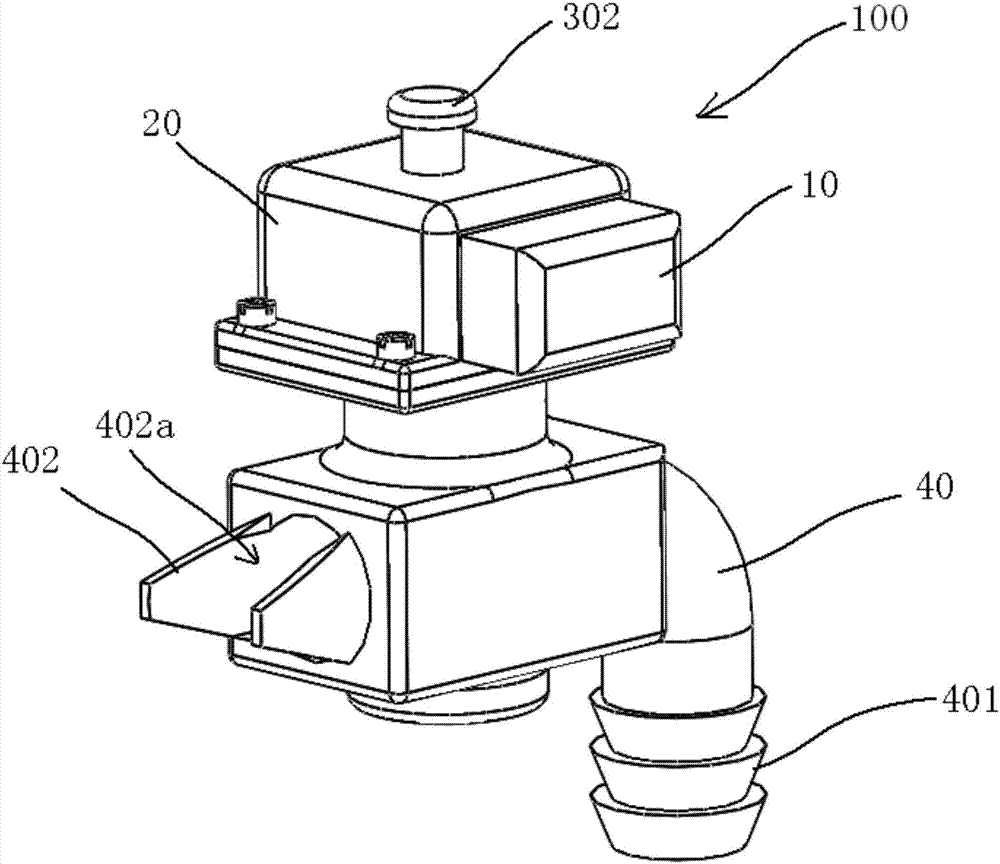

[0046] The automatic degumming device provided in this embodiment includes a degumming unit 100, and the degumming unit 100 includes a degumming pipe 40 and a latex anticoagulant, such as casein, polyacrylamide, etc., and the front end 402 of the degumming pipe 40 can Insert the rubber tree bark A to draw out the latex. That is, the position where the front end 402 of the rubber discharge pipe 40 is inserted is selected for the purpose of being able to draw out the latex, figure 2 Among them, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com