High and low temperature test device for IC testing

A test device, high and low temperature technology, applied in the direction of electronic circuit testing, etc., can solve the problems of interrupting the high and low temperature test process, and achieve the effect of reducing IC damage and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

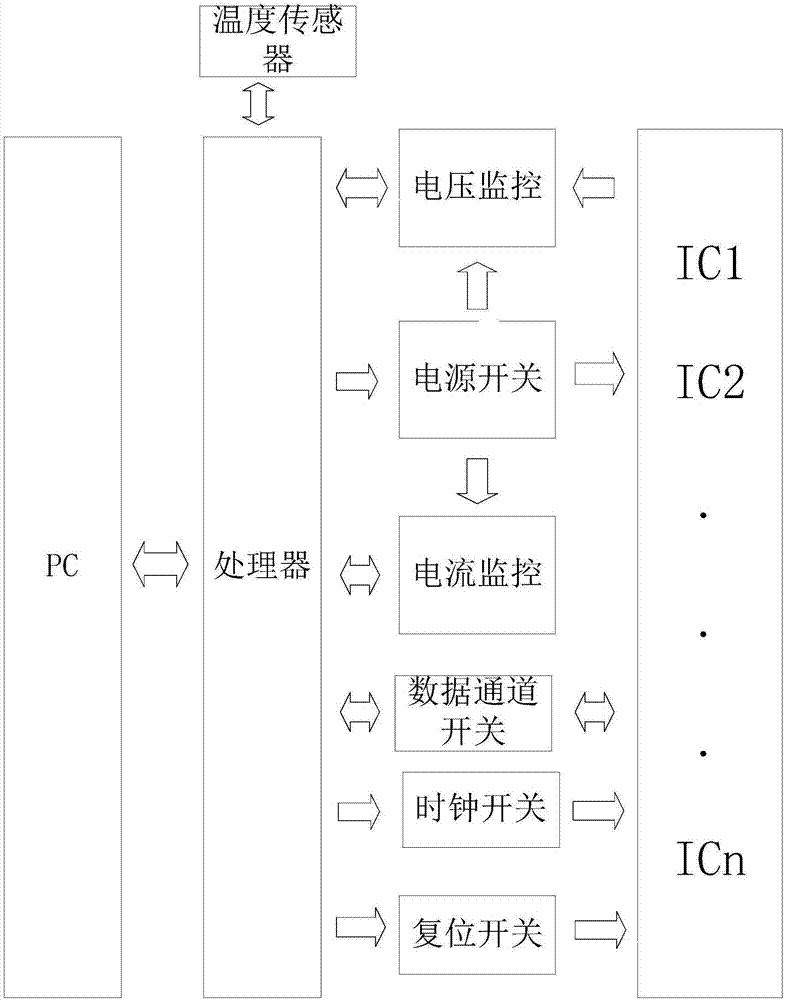

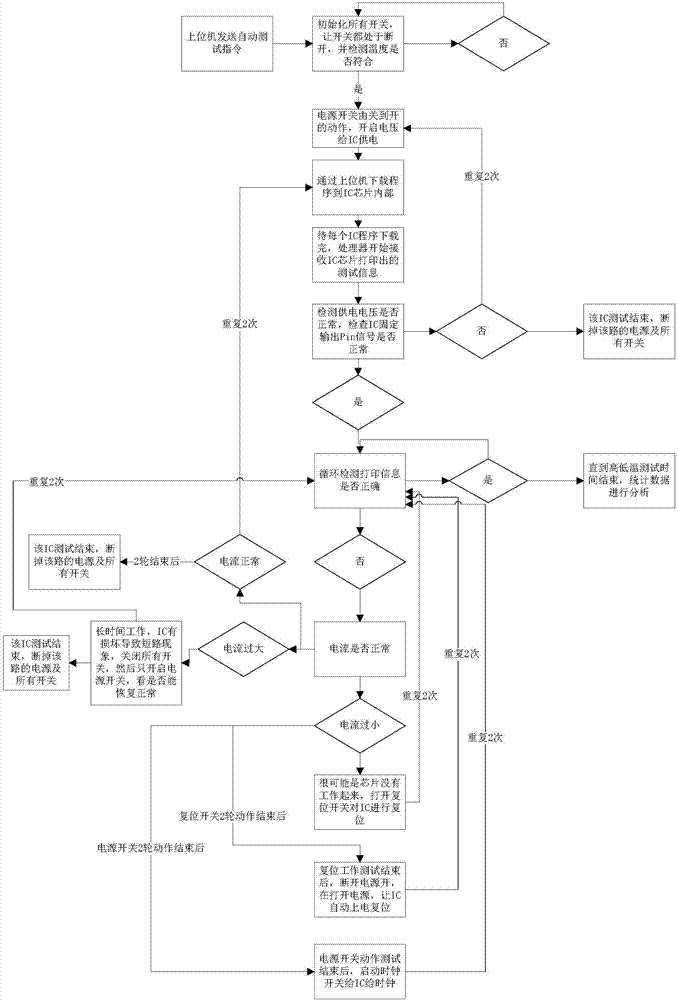

[0043] This embodiment provides a high and low temperature test device applied to IC testing, the high and low temperature test device includes a host computer, the host computer is a PC computer, a hardware circuit connected to the host computer, and a plurality of ICs connected to the hardware circuit The hardware circuit includes a processor, the processor is an ARM processor, a power module connected in parallel with the processor, a current monitoring module, a voltage monitoring module and a switch module; the upper computer is connected and communicated with the ARM processor The processor is used to control the power module, current monitoring module, voltage monitoring module and switch module; the power module is also connected to the voltage monitoring module and the current detection module; the voltage monitoring module is used to detect the IC working voltage; the current detection module is used to detect the working current of the IC; the temperature sensor is u...

Embodiment 2

[0057] On the basis of Embodiment 1, the present embodiment further illustrates the optimization of the correction switch reset correction times, and step (6) is as follows:

[0058] To repair the abnormality, first check the working current of the abnormal IC through the current monitoring module. After the current is too large to be corrected, the cycle detection and printing information are carried out to check whether the correction is successful;

[0059] If the current is too small, correct the current too small, including turning on the reset switch to perform switch reset correction. After correction, check whether the correction is successful by cyclically detecting and printing information. Switch reset and correct 3 times. The correction is successful; if it is not successful, perform 3 power-on reset corrections by turning off and on the power module. After each power-on reset correction, turn on the clock switch to give the IC a clock signal. After the IC receives...

Embodiment 3

[0061] On the basis of Embodiment 1, the present embodiment further illustrates the optimization of the correction switch reset correction times, and step (6) is as follows:

[0062] To repair the abnormality, first check the working current of the abnormal IC through the current monitoring module. After the current is too large to be corrected, the cycle detection and printing information are carried out to check whether the correction is successful;

[0063] If the current is too small, correct the current too small, including turning on the reset switch to perform switch reset correction. After correction, check the printing information to check whether the correction is successful. The switch resets and corrects 5 times. The correction is successful; if it is not successful, perform 5 power-on reset corrections by turning off and on the power module. After each power-on reset correction, turn on the clock switch to give the IC a clock signal. After the IC receives the cloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com