Method for reducing influence of temperature change on optical fiber sensor measurement signal

A fiber optic sensor, temperature change technology, applied in the direction of mitigating undesired effects, etc., can solve the problems of low measurement accuracy and ineffective measurement, achieve the effect of wide application, improve attenuation loss, and solve the problem of temperature cross-sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

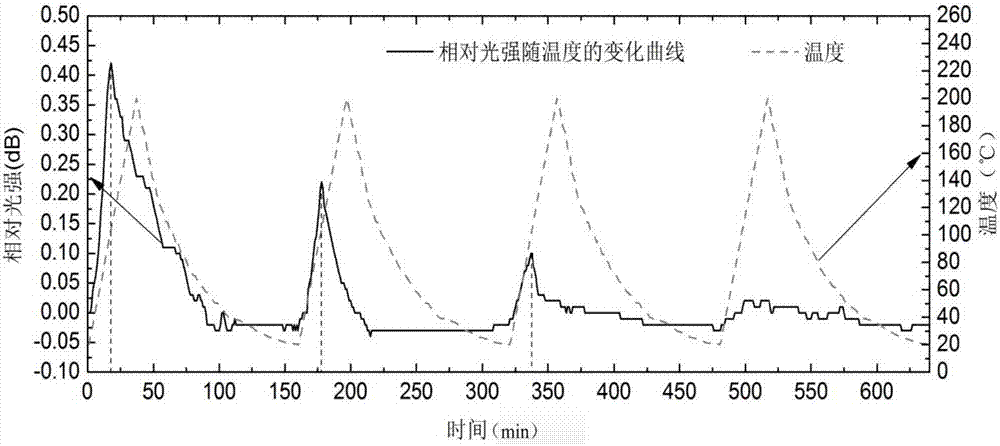

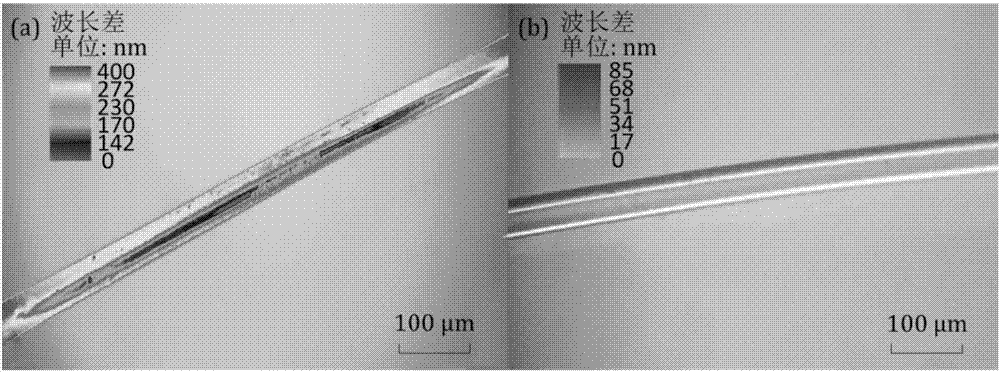

[0031] The tapered optical fiber sensor in this example is made by longitudinal melting and stretching of optical fiber. This process will generate a large amount of residual stress in the optical fiber tapered region, making this type of sensor extremely sensitive to temperature. The specific implementation method of the present invention will be described below in conjunction with the accompanying drawings and the reduction of the influence of temperature changes on the measurement signal of the tapered optical fiber sensor as an example, and the present invention is not limited to this embodiment. Concrete steps of the present invention include:

example 1

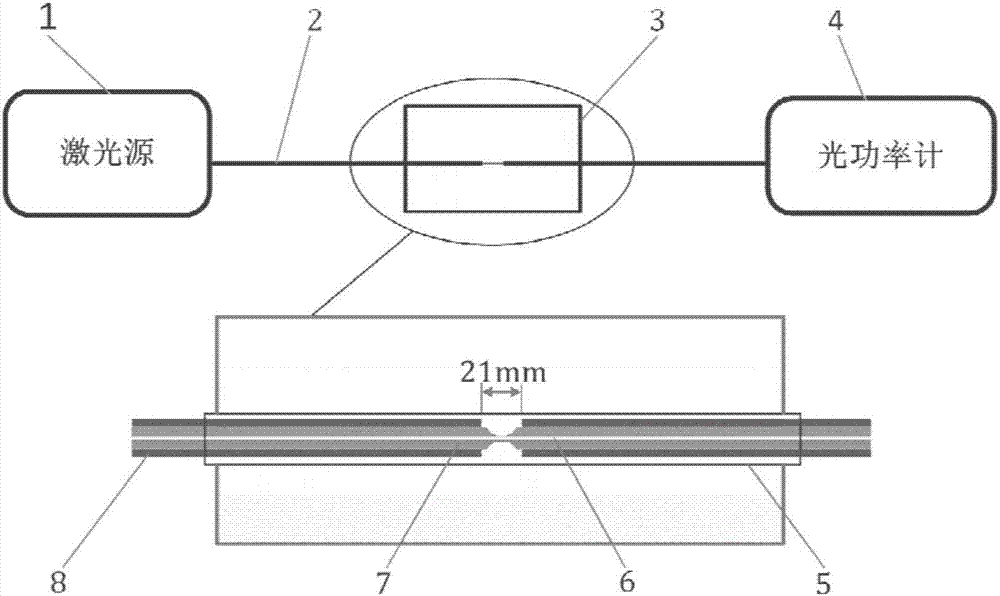

[0033] 1. Cut the single-mode silica fiber 2 (Corning single-mode fiber) 1.5m, and put a 0.3mm diameter quartz capillary into the fiber 2. Then use an optical fiber cutter to cut flat the end faces of the two optical fibers 2, and weld standard connectors on the end faces of the two optical fibers. In order to monitor the tapering process of the optical fiber 2, a 1550 nm laser source 1 is connected to one end of the optical fiber 2 through a standard connector, and an optical power meter 4 is connected to the other end, such as figure 1 shown in the upper part.

[0034] 2. Remove the 1.5cm-long optical fiber coating layer 8 from the middle part of the optical fiber, and clean the area with alcohol. Then it is clamped on the optical fiber tapering instrument for tapering. Set the tapering speed to 0.5 mm / s, the flame temperature to 1000 °C, and the diameter of the cone to 35 μm. Check the change of the light intensity of the optical power meter 4 after tapering to judge the...

example 2

[0041] The difference between this example and Example 1 is that multiple optical fiber sensors are processed at the same time, but when processing multiple optical fiber sensors at the same time, it is necessary to ensure that the maximum temperature difference between adjacent optical fibers is less than 20 degrees Celsius, and the rest is the same as the above Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com