Drying system for drying granular materials

A technology of granular material and drying system, applied in the direction of granular material drying, drying, dryer, etc., can solve the problem of large total energy consumption for secondary drying of the dryer, and save the total energy consumption and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

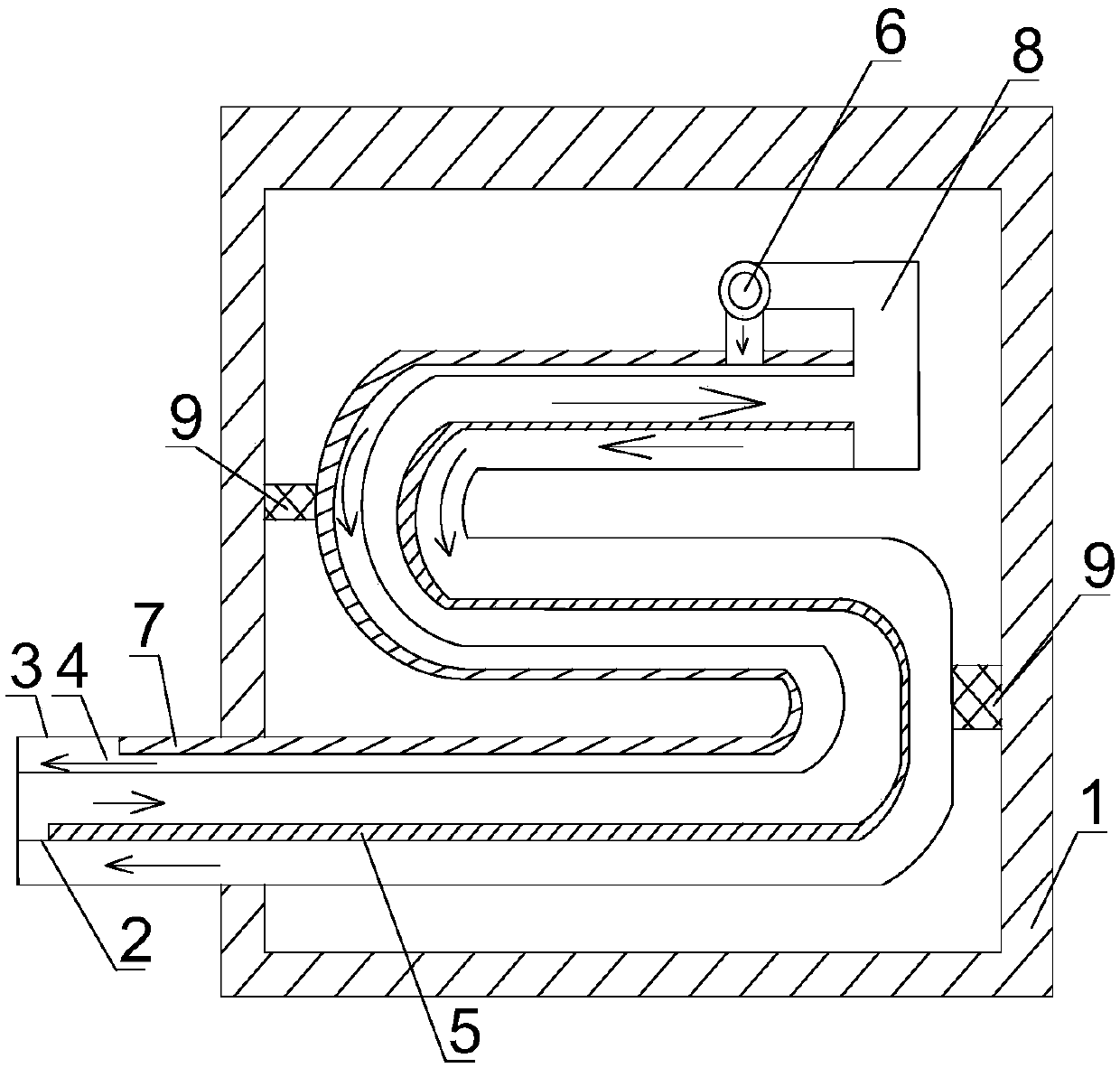

[0022] Such as figure 1 As shown, the drying system for drying granular materials of the present invention includes a body 1, a drying pipe is installed inside the body 1, and the drying pipe includes a serpentine heating pipe 2, which is sleeved on the outside of the serpentine heating pipe 2. Serpentine sleeve 3, there is an annular channel 4 between the serpentine sleeve 3 and the serpentine heating tube 2, the inner wall of the serpentine heating tube 2 is covered with an electric heating film 5, the inlet of the serpentine heating tube 2 The feed port is located at the bottom of the body 1, and the discharge port of the serpentine heating tube 2 is located at the top of the body 1. The discharge port of the serpentine heating tube 2 is connected with a circulation pump 6, and the discharge port of the circulation pump 6 is connected to the inlet of the annular channel 4. The feed port is connected, the feed port of the annular channel 4 is close to the discharge port of t...

Embodiment 2

[0025] Based on Example 1, the inner wall of the serpentine sleeve 3 is covered with a thermal insulation layer 7, the thermal insulation layer 7 includes a silicone rubber layer bonded to the inner wall of the serpentine sleeve 3, and the silicone rubber layer is close to the snake. The surface of the shaped heating pipe 2 is covered with a polyurethane insulation layer. The insulation layer is used to prevent heat loss inside the annular channel and keep the heat in the annular channel sufficient to dry materials. Silicone rubber not only has the good adhesiveness of rubber, but also has the moisture-proof, waterproof, temperature-resistant and insulating properties of silicone, and the thermal insulation performance of polyurethane. Well, it can effectively prevent heat loss.

Embodiment 3

[0027] Based on the above embodiment, a plurality of springs 9 are connected between the outer wall of the serpentine sleeve 3 and the inner wall of the body 1 , and each spring 9 is sleeved with a casing. The spring has a shock absorbing effect, and the materials entering the serpentine heating tube and the annular channel are all pressurized, and the spring has a certain buffering effect to avoid unstable fixation between the serpentine sleeve and the body; the outer shell of the spring is used for Therefore, when the spring is deformed, the displacement and deflection will not occur, so that the service life of the spring is longer, and the connection between the serpentine sleeve and the inner wall of the body is stronger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com