Ultrahigh-pressure fully-automatic pressure relief device

A pressure relief device, fully automatic technology, applied in the direction of fluid pressure actuating device, servo motor components, mechanical equipment, etc., can solve the problems of inability to achieve linear changes in system pressure, low pressure relief accuracy, and poor distance control. The effect of avoiding long-term pressure, smooth pressure relief, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

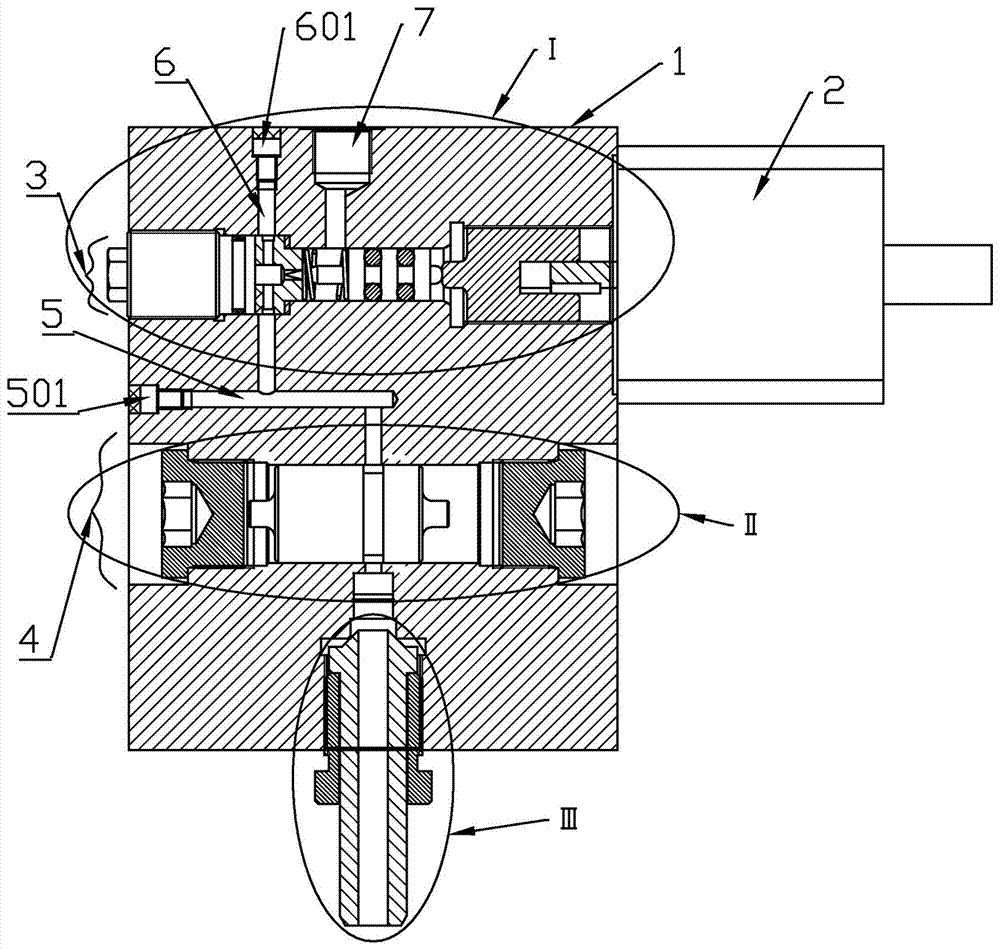

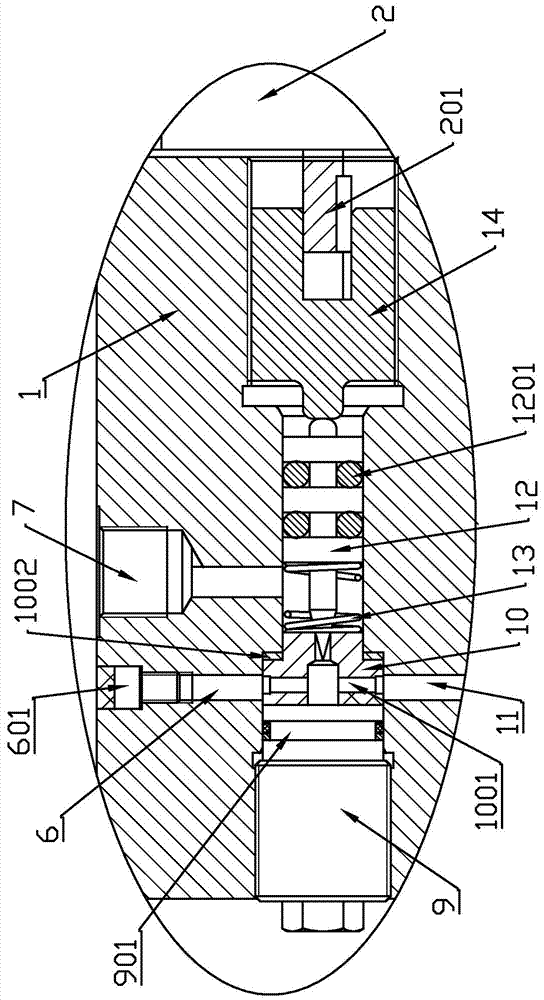

[0030] Embodiment one, such as Figure 1-3 , 6, 7 An ultra-high pressure automatic pressure relief device, including a main body 1 and a stepper motor 2 located on the right side of the main body 1, the main body 1 includes a pressure relief chamber 3 transparent on both sides, and the pressure relief chamber 3 Including the blocking cavity on the left, the regulating cavity on the middle and the threaded cavity on the right;

[0031] The plug I9 on the left side and the valve seat 10 on the right side are provided in the plugging cavity, the valve seat 10 is provided with a cross-shaped valve port 1001, and the top and bottom of the plugging cavity are respectively provided with The safety hole 6 and the first oil inlet hole 11, the safety hole 6 and the first oil inlet hole 11 are both connected to the valve port 1001, and the outlet of the safety hole 6 is provided with a safety valve I501;

[0032] There is a thimble 12 which is thinner on the left and thicker on the righ...

Embodiment 2

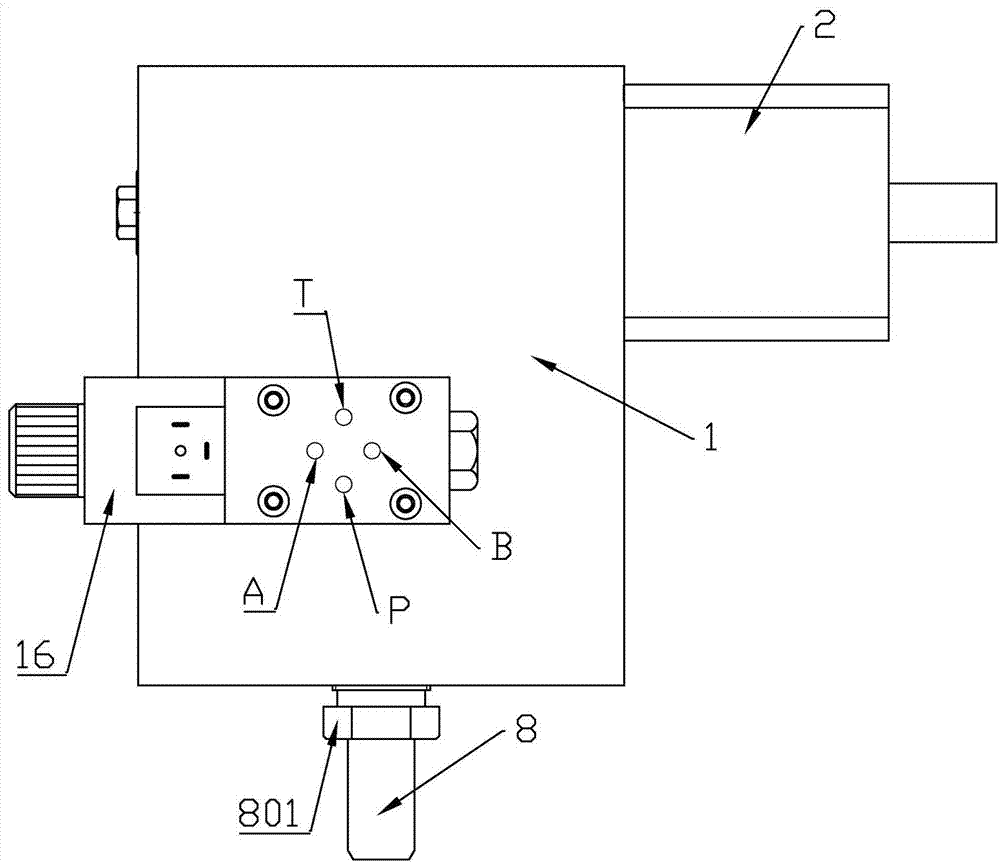

[0048] Embodiment two, such as Figure 1-7, basically the same as Embodiment 1, the difference is that it also includes a solenoid valve 16 installed on the main body 1, the solenoid valve 16 is a two-position four-way hydraulic solenoid valve 16, and the solenoid valve 16 is provided with an A port , B port, P port and T port, the main body 1 also includes a pressure-holding chamber 4 transparent at both ends, the two ends of the pressure-holding chamber 4 are blocked with screw plugs II15, and the spool of the solenoid valve 16 1601 is located in the pressure-holding chamber 4, the A port communicates with the left side of the pressure-holding chamber 4, the B oral language communicates with the right side of the pressure-holding chamber 4, the P port communicates with the hydraulic pump, and the T port communicates with the return The oil tank is connected, the valve core 1601 is provided with an annular groove 1602 close to the right end, and the second oil inlet hole 18 o...

Embodiment 3

[0049] Embodiment three, such as Figure 1-5 , is basically the same as Embodiment 1 or Embodiment 2. Preferably, the right side of the screw plug I9 is provided with a seal groove I901 for installing a gasket, and the right half of the thimble 12 is provided with at least two seal grooves for installing a gasket. Sealing groove II 1201, the right side of the valve seat 10 is provided with a copper gasket 1002 located at the rightmost end of the sealing cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com