Sprayer switch

A sprayer and switch technology, which is applied to spray devices, liquid spray devices, etc., can solve the problems of high labor intensity, short service life, and laborious operators, and achieve the effect of reducing labor intensity, avoiding long-term pressure and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

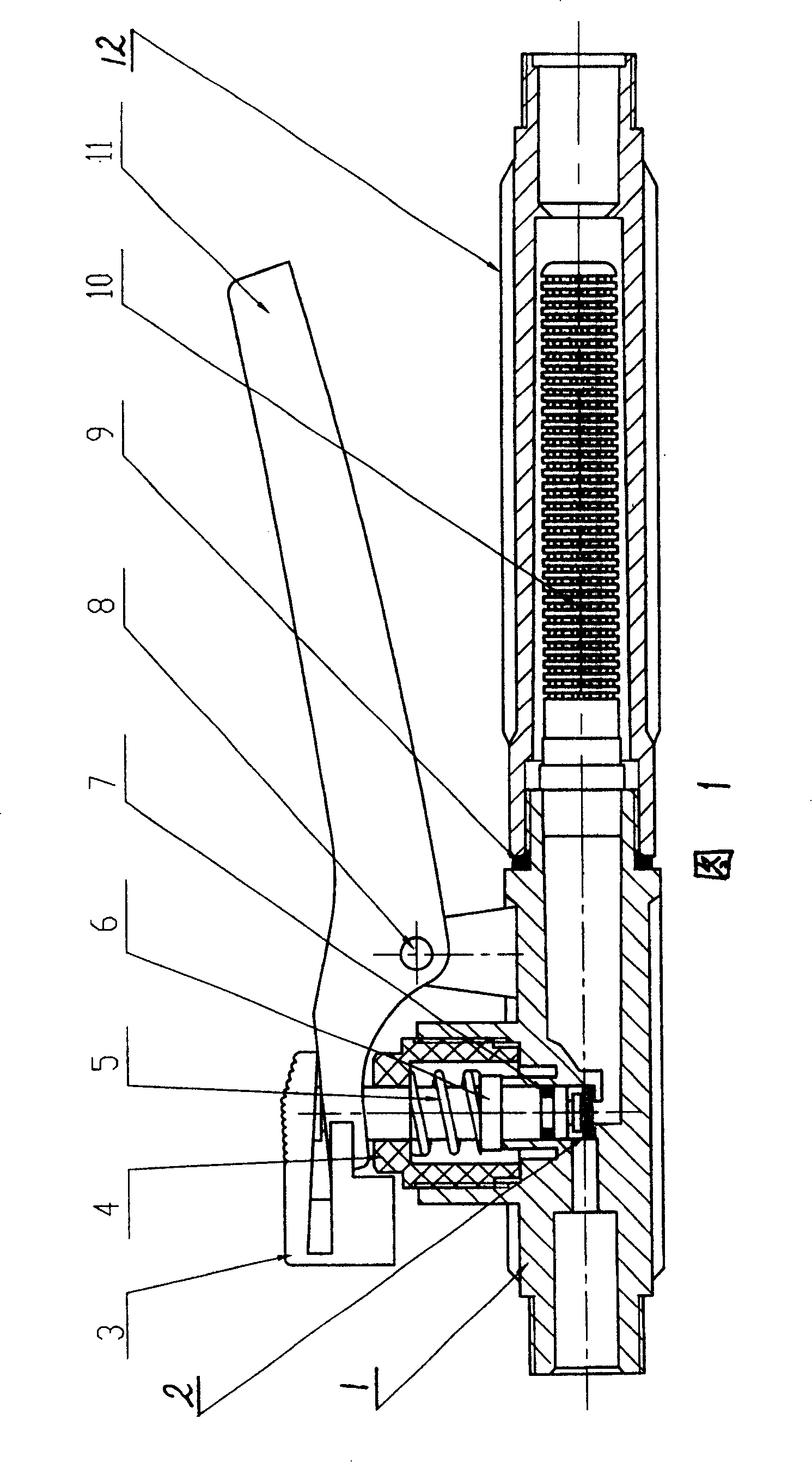

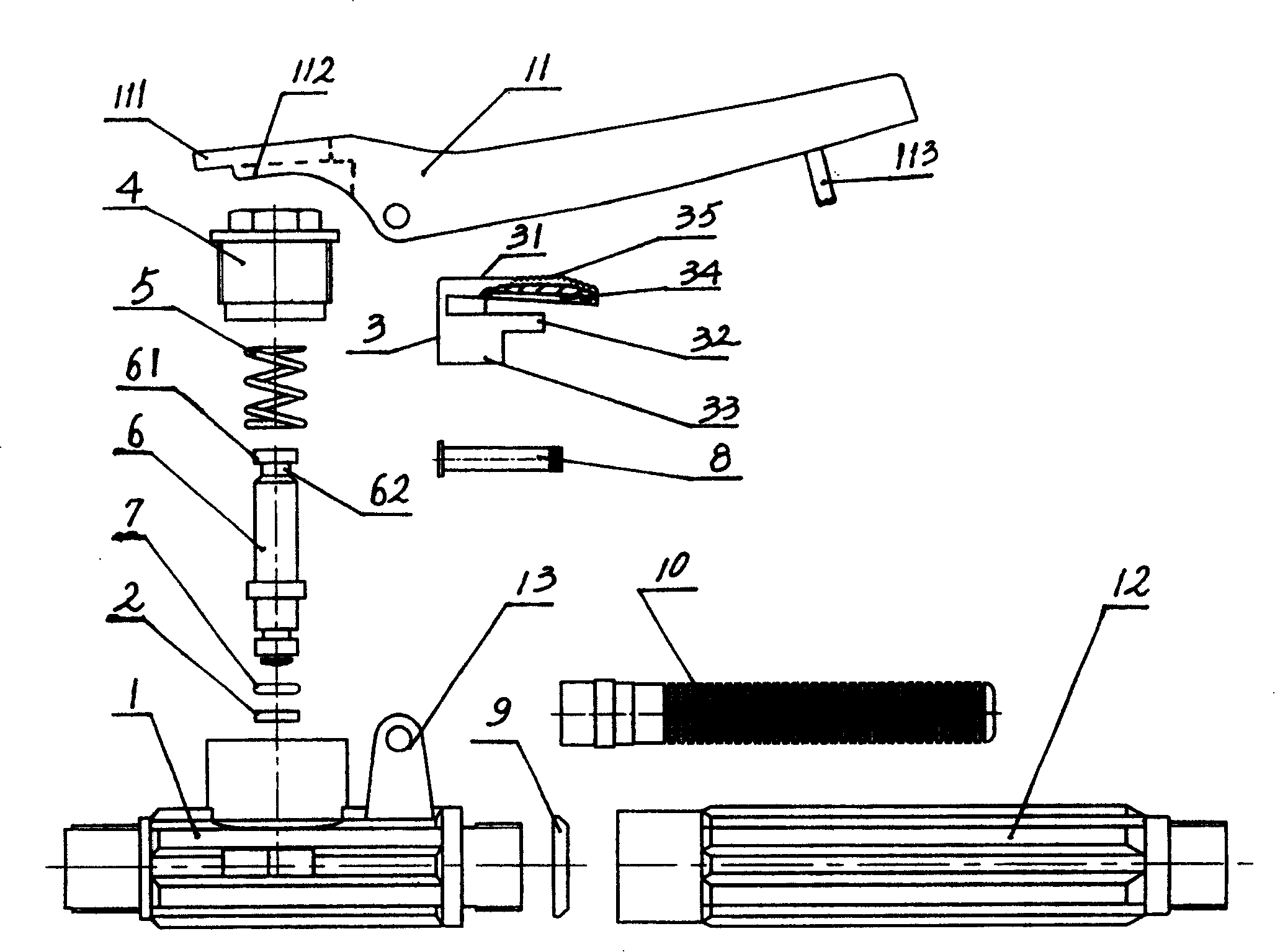

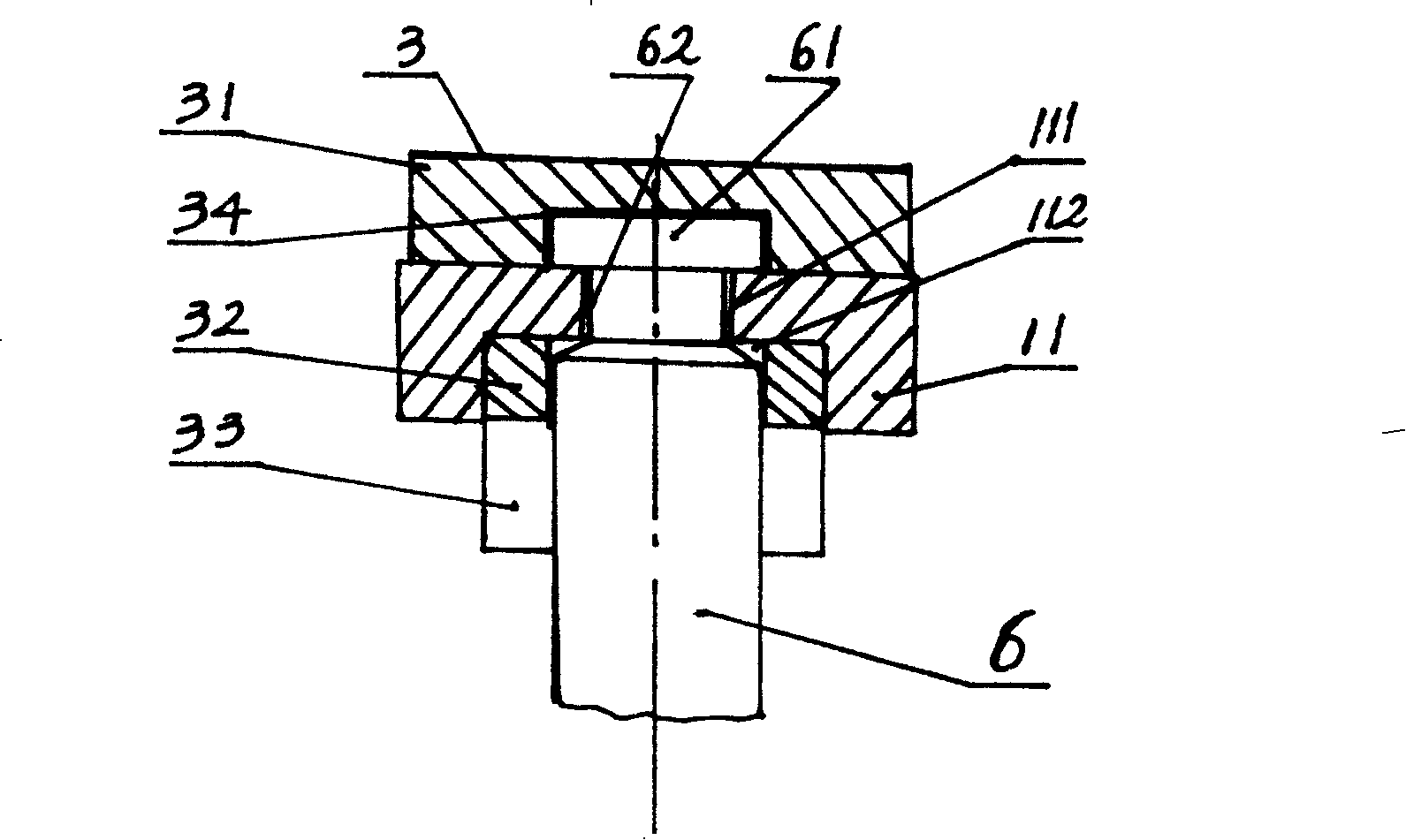

[0009] The invention discloses a sprayer switch. As shown in FIG. 1 , there is a switch main body 1, a handle 12 is connected to the center of the switch main body 1, and a valve core 6 is installed in the vertical direction of the switch main body 1. The valve core 6 There is a sealing device and a reset closing spring 5 between the body and the spring 5. There is a fixed switch nut 4 on the spring 5. The outer end (top) of the valve core is connected to a wrench 11. The wrench 11 is connected to the switch body 1, and the switch body 1 is connected to the handle. One end of the spool is formed with a bracket 13, which is connected to the wrench 11 by the bracket. The bracket is used as the lever fulcrum of the wrench during work. It is characterized in that a limit cap 3 is installed between the wrench 11 connected to the outer end of the valve core 6 and the switch nut 4, as shown in Fig. 1 Shown is that the sprayer is not working, the limit block 33 at the bottom of the lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com