Push type liquid pump

A liquid pump, push-type technology, applied in the field of liquid pumps, can solve problems such as deformation of the ball or valve seat, difficulty in control, and difficulty in proper sealing of one-way ball valves, and achieve the effect of avoiding deformation and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]First of all, by the way, the "up" and "down" mentioned in this article are determined relative to the liquid pump being placed in a vertical orientation (that is, the liquid pump is set so that its axis direction is consistent with the vertical direction) .

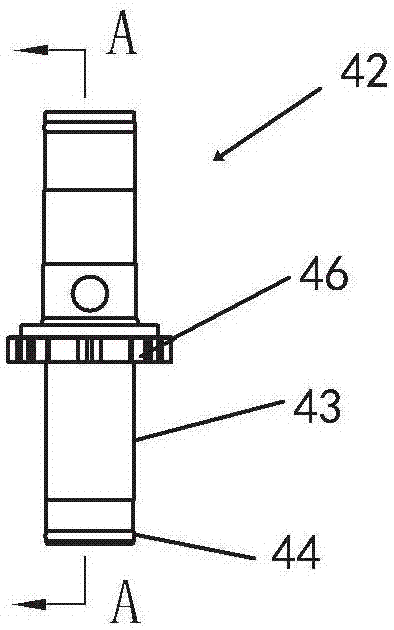

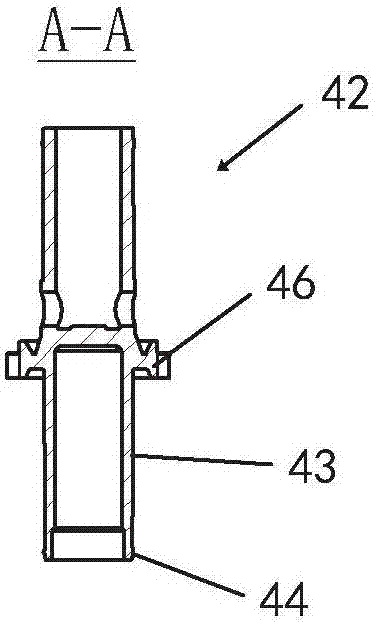

[0034] see figure 1 - 4b, which shows a first embodiment of the invention. The liquid pump mainly includes a pressure head 10 with an outlet, a cylinder 20 defining a liquid storage tank 30, and is slidably arranged in the liquid storage tank 30 along the axial direction and connected with the pressure head 10 so as to be able to move up and down in the liquid storage tank 30. The reciprocating piston assembly 40, the helical metal compression spring 50 (that is, the elastic return device) arranged in the liquid storage tank 30 for applying an upward bias to the piston assembly 40 in the axial direction, and the The lower one-way valve 60 at the bottom of 30 is used to control the one-way communication between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com