Variable-structure rocket based combined power cycle engine

A technology of combined power and variable structure, applied in combined engine, machine/engine, ramjet engine, etc., can solve the problem of no combustion chamber variable structure scheme, and achieve easy realization, reduce heat load, and simple variable structure method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

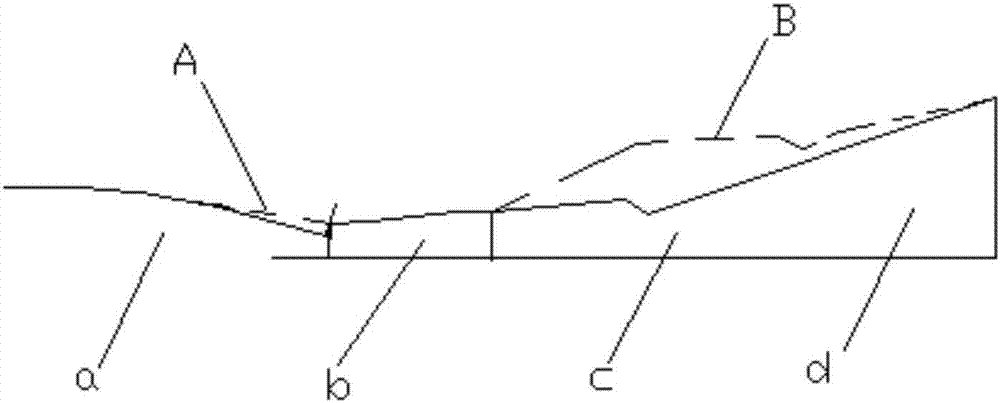

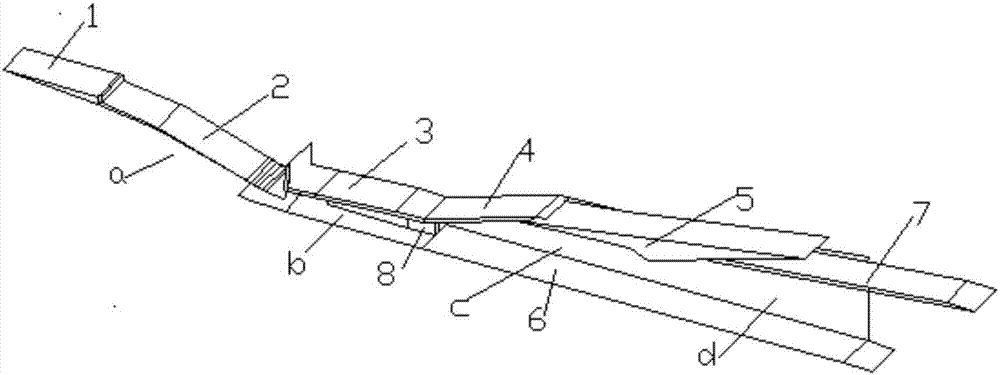

[0014] The variable structure rocket-based combined power cycle engine of the present invention, such as figure 1 and figure 2 As shown, it includes a variable structure combustion chamber c, which is a cavity surrounded by an upper top plate, side plates and a fixed bottom plate 6, and the upper top plate includes a slidingly connected combustion chamber fixed top plate 4 and an adjustable combustion chamber from front to back. The top plate 5 has the same width. The fixed top plate 4 of the combustion chamber is inclined upward from front to back, and the adjustable top plate 5 of the combustion chamber slides reciprocally along the direction of the fixed top plate 4 of the combustion chamber; the fixed top plate 4 of the combustion chamber is the incoming flow inlet port ; In the injection mode, the adjustable top plate 5 of the combustion chamber is located at the rear end of the fixed top plate 4 of the combustion chamber to maximize the expansion ratio of the combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com