Method for preventing rubber water-stop belt from deviating

A technology of rubber waterstops and rubber waterstops, which is applied to building components, building insulation materials, buildings, etc., to achieve the effects of improving construction efficiency, simple construction procedures, and convenient materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further specifically described below through specific examples, but the present invention is not limited to the examples.

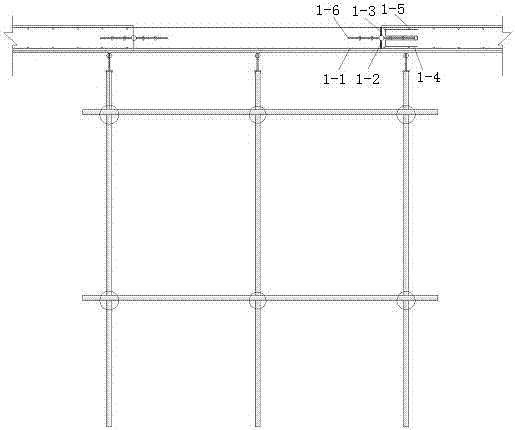

[0017] As shown in the figure; construction process: bind the steel bars at the bottom of the slab, install the first steel wire mesh, install the rubber waterstop, install the second steel mesh, install the rubber waterstop fixing device, bind the surface layer steel bars, and pour concrete , construction joint cleaning, finished product protection.

[0018] A method for preventing the displacement of rubber waterstops according to the present invention comprises the following construction steps:

[0019] Step 1. After the formwork support system is accepted and accepted, the construction of the reinforcement project is started; firstly, the binding work of the steel mesh 1-1 at the bottom of the slab is completed according to the design requirements;

[0020] Step 2. After the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com