Anchoring-device-free prestress high-strength steel stand mesh U-shaped concrete member reinforcing method

A technology of prestressed steel strand and anchoring device, which is applied in bridge reinforcement, building construction, erection/assembly of bridges, etc., can solve the problems of easy cracking, increase the self-weight of the beam, increase the thickness of the mortar reinforcement layer, etc., to achieve convenient construction, Improve construction efficiency and use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

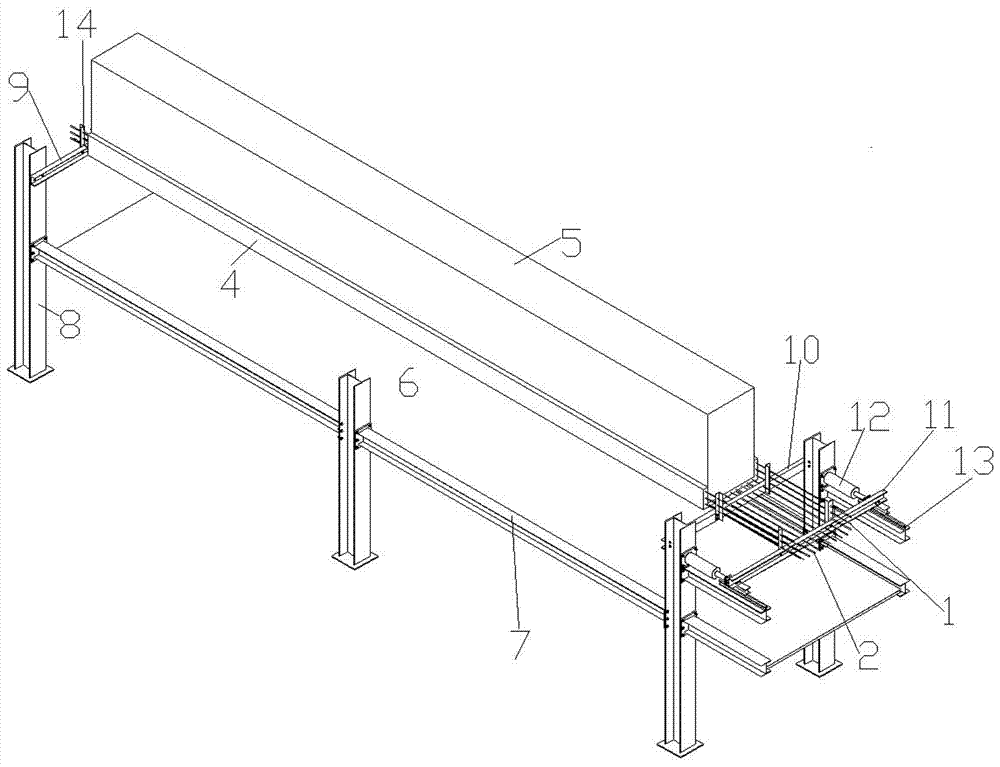

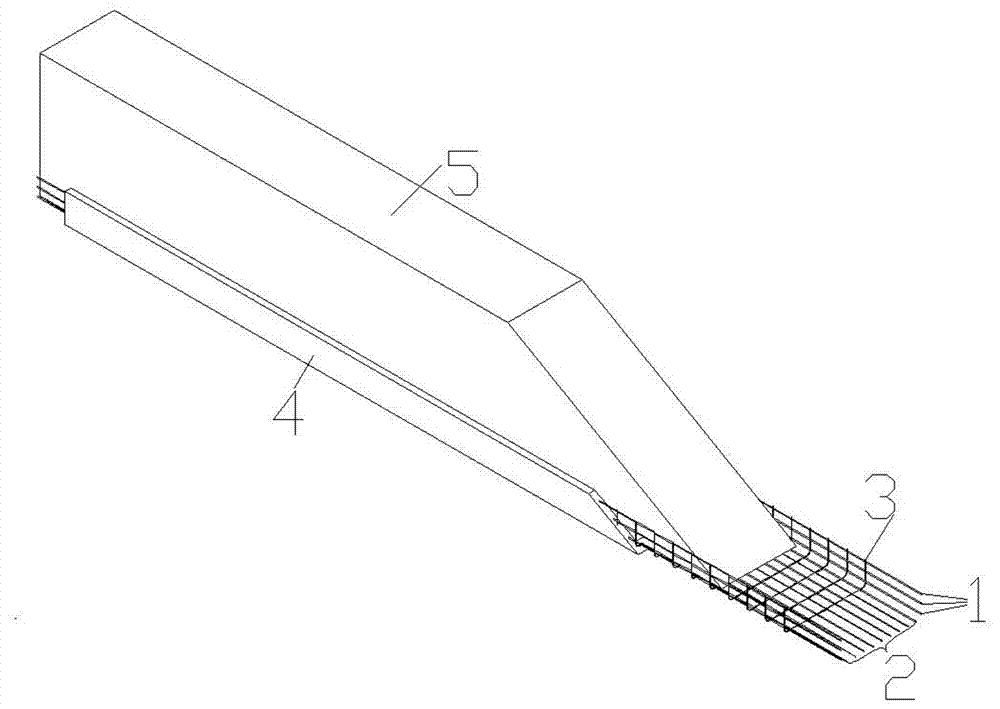

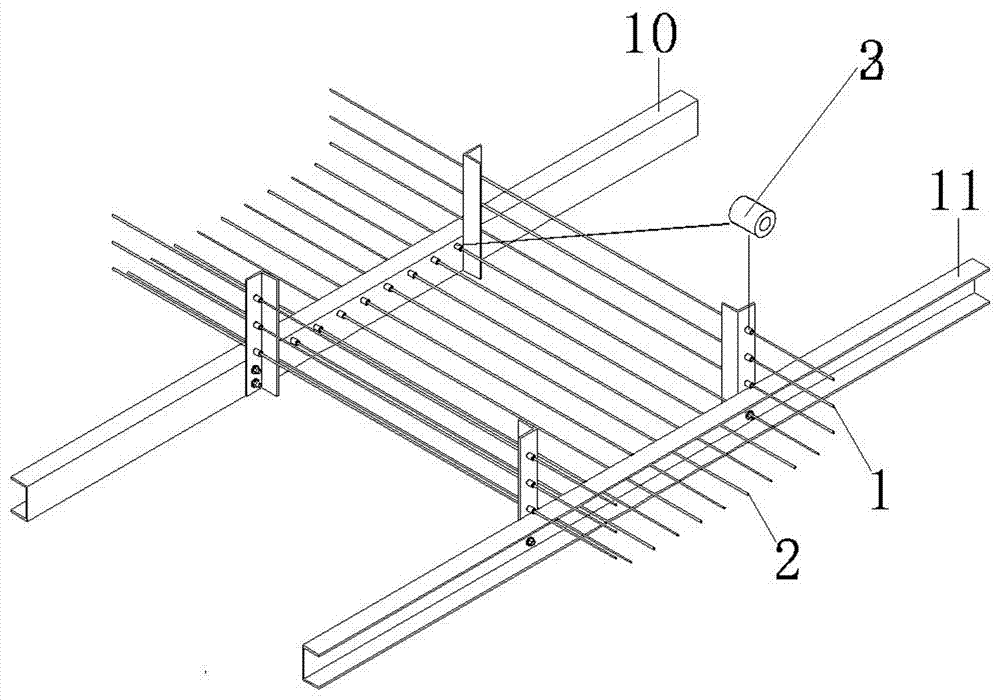

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as Figure 1-4 As shown, a method for U-shaped reinforcement of concrete members with prestressed high-strength steel strand nets without anchoring devices, including the bottom of the reinforced concrete beam to be reinforced is provided with a U-shaped reinforcement system for reinforcement, and the U-shaped reinforcement system includes cladding The U-shaped mortar fixed layer at the bottom of the reinforced concrete beam to be reinforced, the prestressed steel strands of the bottom plate arranged at longitudinal intervals, the prestressed steel strands of the web plate and the transverse U-shaped steel strands arranged at intervals in the transverse direction (the prestressed steel strands of the bottom plate are used in the actual implementation process) High-strength steel strands, web prestressed high-strength steel strands and transve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com