A functional bacterium for degrading oily sludge and its application

An oil sludge and bacteria technology, applied in the field of environmental microorganisms, can solve the problems of long repair cycle, shorten the repair time and improve the degradation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1, Isolation, Purification and Identification of Oily Sludge Degrading Bacteria C-5

[0034] (1) Preparation of culture medium

[0035] Enrichment medium: LB medium, beef extract 3g, peptone 10g, sodium chloride 5g, distilled water 1000ml, pH adjusted to 7.0-7.2, if using solid medium, add 2% agar.

[0036] Inorganic salt medium: NaCl 1.0g, (NH4) 2 · SO 4 0.617g, KH 2 PO 4 0.50g, K 2 HPO 4 1.0g, MgSO 4 0.50g, CaCl 2 0.1g, KCl 0.10g, FeSO 4 ·7H 2 O 0.01g, distilled water 1000ml, adjust the pH to 7.0-7.2, if it is mixed with solid medium, add 2% agar.

[0037] Selection medium: inorganic salt medium + agar + 0.1% oil

[0038] Acclimatization medium: inorganic salt medium + agar + (0.1%, 0.2%, 0.5%, 1%) oil

[0039] Re-screening medium: inorganic salt medium + 1% oil

[0040] All the above media were sterilized in a high-pressure steam sterilizer at 121°C for 20 min before use.

[0041] (2) Sample source:

[0042] Oily sludge: collected from oil-co...

Embodiment 2

[0081] Example 2 Performance measurement of oily sludge degrading bacteria C-5.

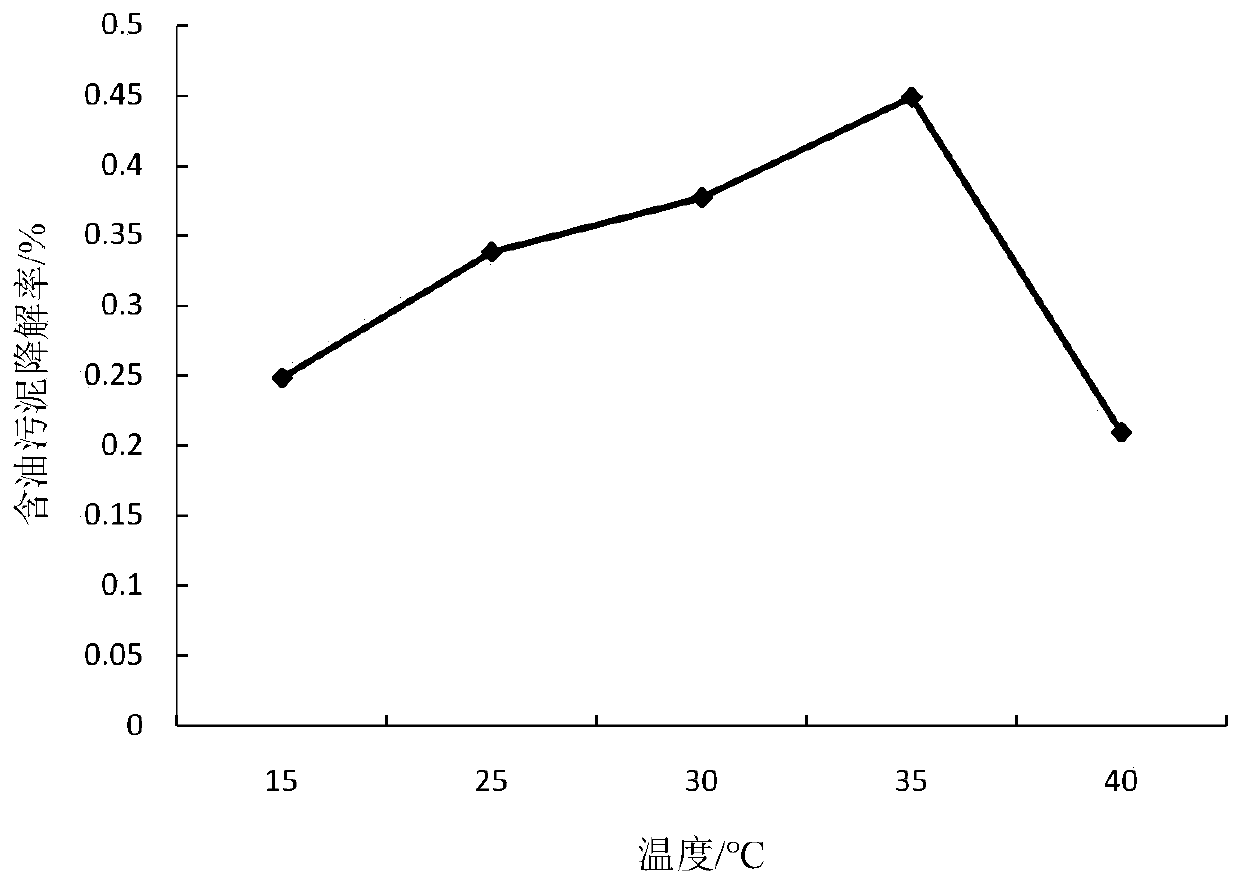

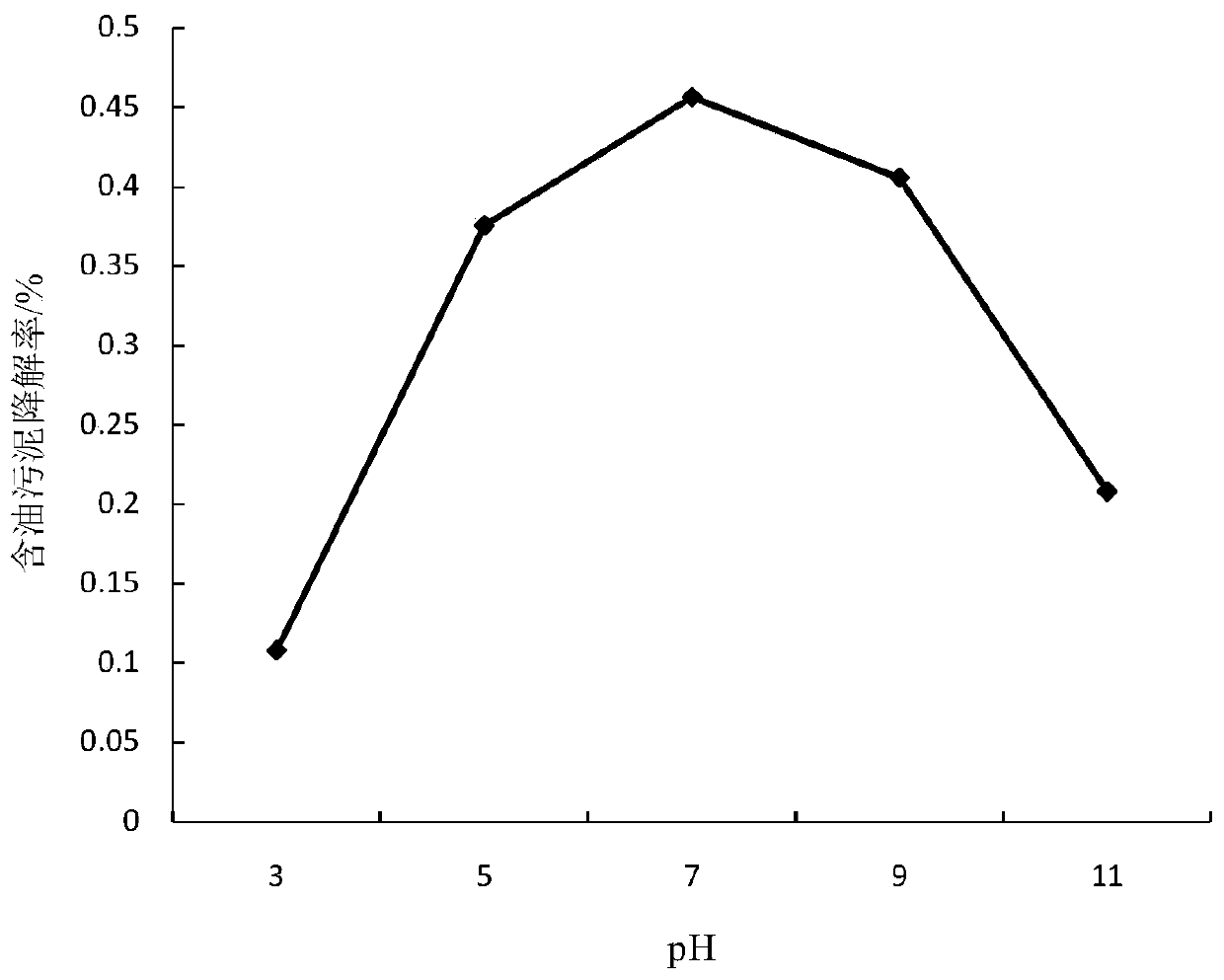

[0082] (1) Degradation of crude oil by bacterial strains at different temperatures

[0083] The bacterial suspension of the C-5 strain was inserted into the inorganic salt medium according to the inoculum amount of 10% (v / v), and the crude oil content was added to 1000 mg / L. An equal amount of phosphate buffer (pH) was used instead of the bacterial suspension as a control. Set 5 groups of different reaction temperatures: 15°C, 25°C, 30°C, 35°C, 40°C, considering the ability of C-5 strain to degrade crude oil at different temperatures. After the sample was placed in a constant temperature incubator at 190 rpm and incubated at 35°C for 7 days, the crude oil content in the sample was measured, and the degradation rate was calculated. This experiment and all experimental groups involved in the following are equipped with 3 parallel and blank control groups. The test results can be found in the att...

Embodiment 3

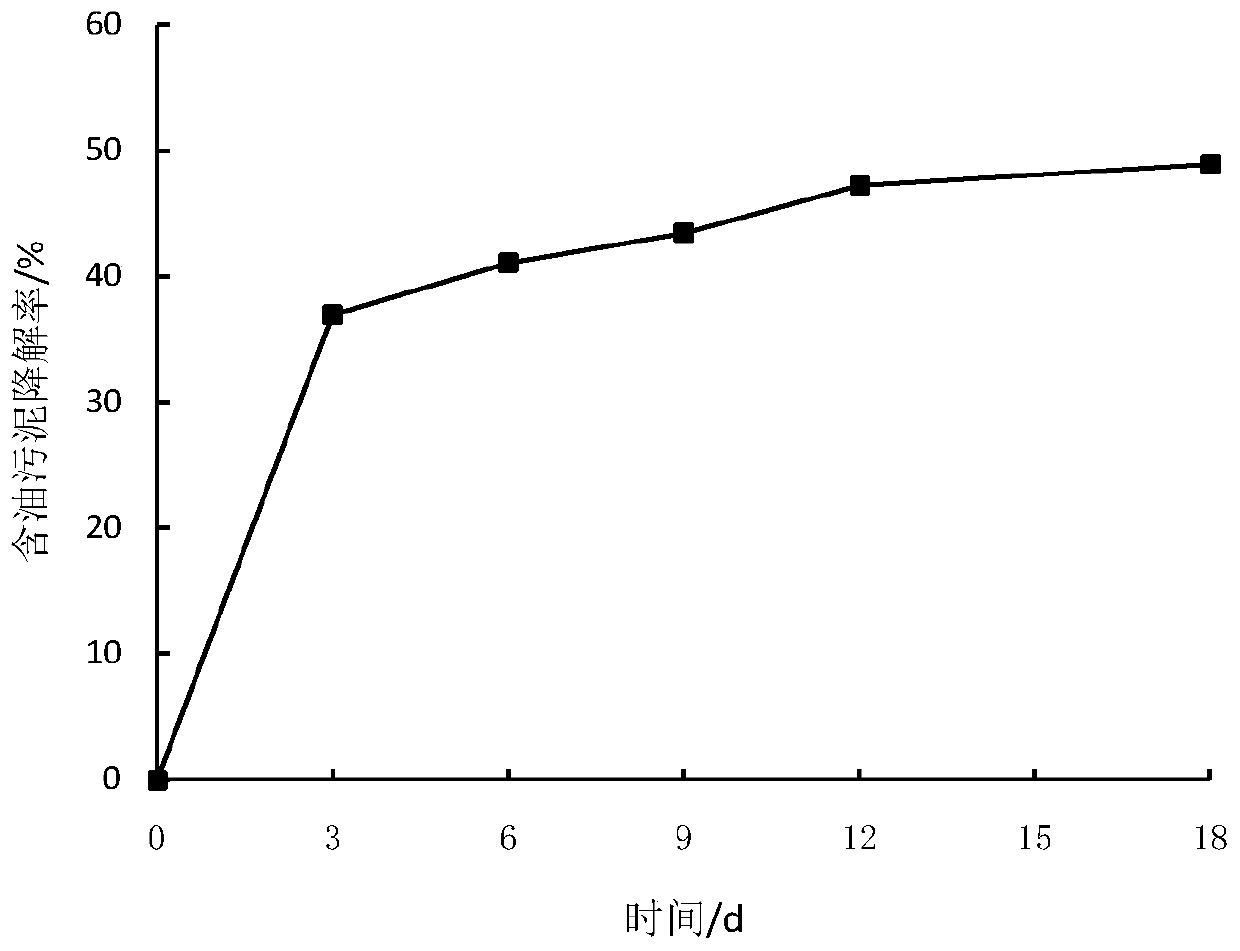

[0096] Example 3 Comparative experiment on the degradation of organic components of oil-based mud drilling cuttings by C-5 functional bacteria

[0097] experimental method

[0098] C-5 Functional Bacteria Degradation Experiment Group: Prepare five 500ml Erlenmeyer flasks, weigh 50g oil-based mud drilling cuttings respectively, add a certain amount of inorganic salt medium to each Erlenmeyer flask, and keep the water content at about 86%. For each strain at its optimum pH (7.0), optimum temperature (35°C), optimum N-P ratio (12:1) and optimum NaCl concentration (0.5%, ie 5g / L), the inoculum was 10% respectively Insert the functional bacteria C-5, and culture it in a shaker at 190rpm / min at 35°C for 15 days, then centrifuge the oil-based mud drilling cuttings at 5000rpm / min for 10 minutes, pour off the supernatant, and let the sludge air dry naturally.

[0099] Put the air-dried oil sludge into a 250ml Erlenmeyer flask, add 100ml of petroleum ether (30-60°C) and extract in a sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com