A heavy oil fission viscosity reduction treatment device

A processing device and a technology for reducing viscosity, which can be used in the treatment of hydrocarbon oil, the refining and cracking process of only multi-stage series, and the petroleum industry. It can solve the problems of low production efficiency and inability to save thin oil resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

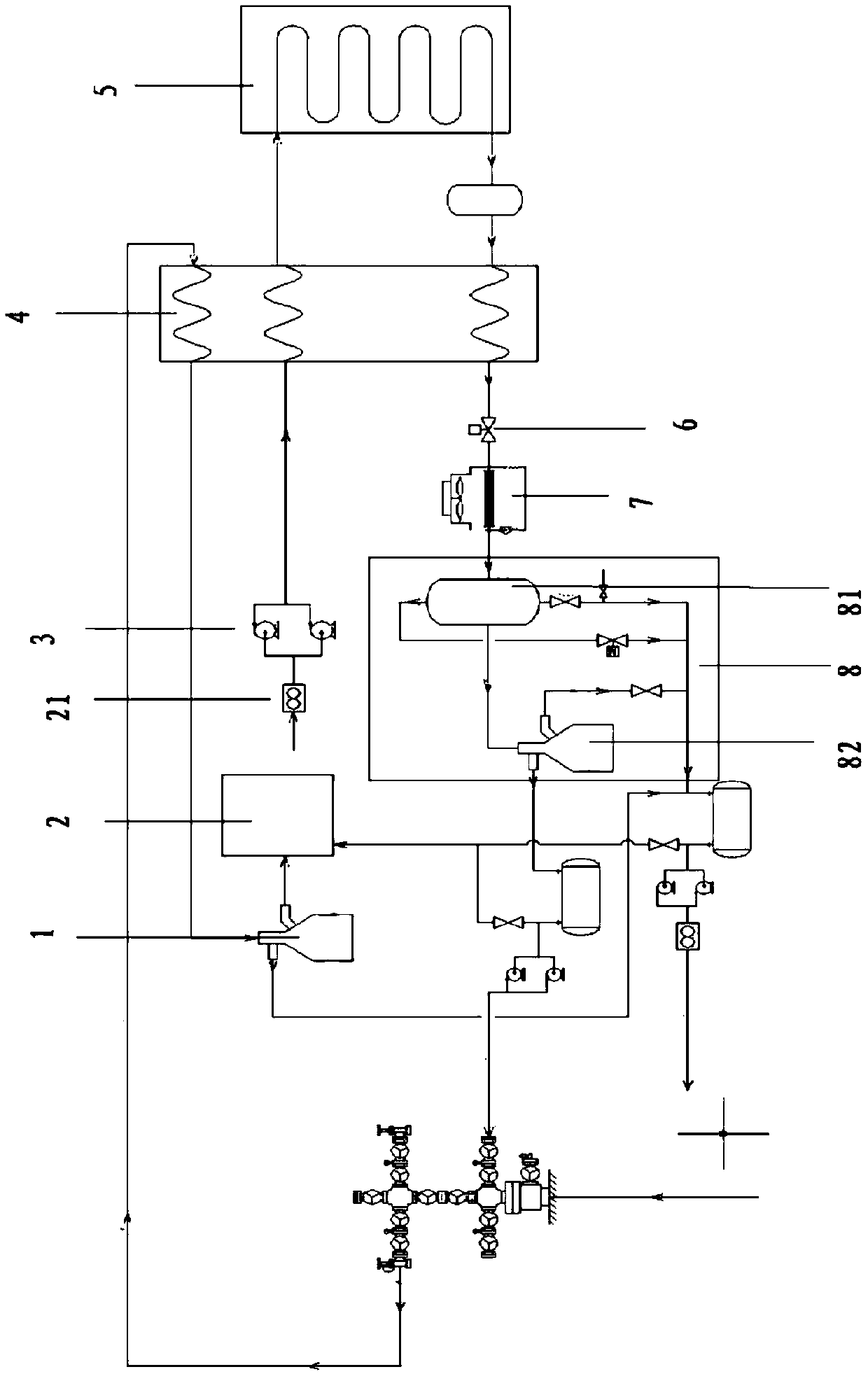

[0030] This embodiment provides a heavy oil fission viscosity reduction treatment device, please refer to figure 1 , the device includes:

[0031] Centrifuge 1, the centrifuge 1 receives the mixed liquid from the mixed liquid in the well, and separates the mixed liquid from oil and water to obtain crude oil and water; the centrifuge 1 also includes: a vertical shaft; a drum, the rotating drum The drum is connected to the upper end of the vertical shaft and is driven to rotate by a motor through a transmission device; the feeding pipe is located at the center of the drum; the disc is located inside the drum and is connected to the feeding pipe The lower end is connected to expand the deposition area of the drum. The discs are stacked with each other with gaps, and the number of the discs is at least two.

[0032] Specifically, according to the water content analysis of the crude oil sampled from the No. 2 Oil Production Plant of Tahe Oilfield, the test results show that the...

Embodiment 2

[0054] This embodiment provides a fission viscosity reduction treatment method for heavy oil. The mixed solution (95° C.) is advanced into the centrifuge 1 to separate 10% water contained in the mixed solution. This part of the water has a high degree of mineralization. If it is not separated, the salt in the water will form salt scale inside the pipeline and the inner wall of the heating furnace tube, which will block the pipeline, make the heating furnace unable to exchange heat, and eventually lead to system failure. The crude oil after separation is about 19t / d, and enters the buffer tank 2 for buffering. The buffer tank 2 is equipped with a liquid level gauge display, and the front end is equipped with automatic drip irrigation. The function of the buffer tank 2 is to buffer incoming crude oil to prevent the booster pump 3 from being sucked up due to large flow changes. Then the crude oil enters the booster pump 3 to pressurize to 10-25MPa and then is heated to 345°C by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com