Plate fixed-length intelligent cutting equipment

A cutting and fixed-length technology, which is applied to shearing equipment, metal processing equipment, shearing devices, etc., can solve the problems of manual measurement, inconvenient operation, and high work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

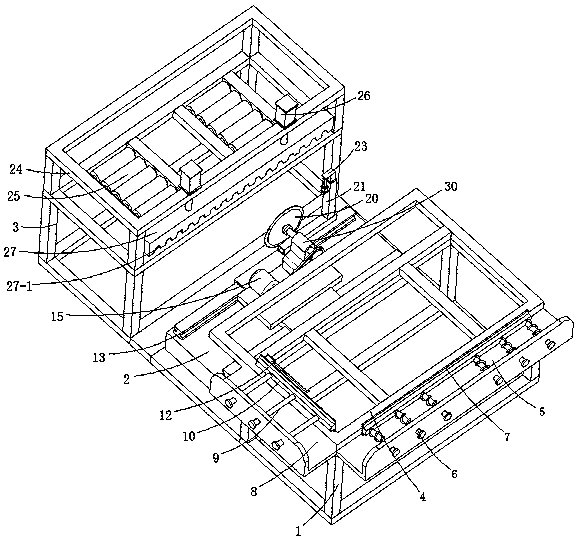

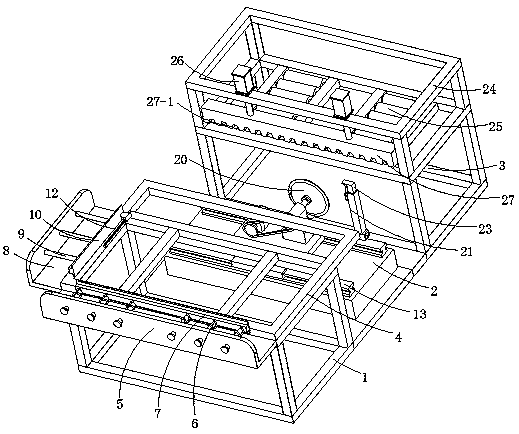

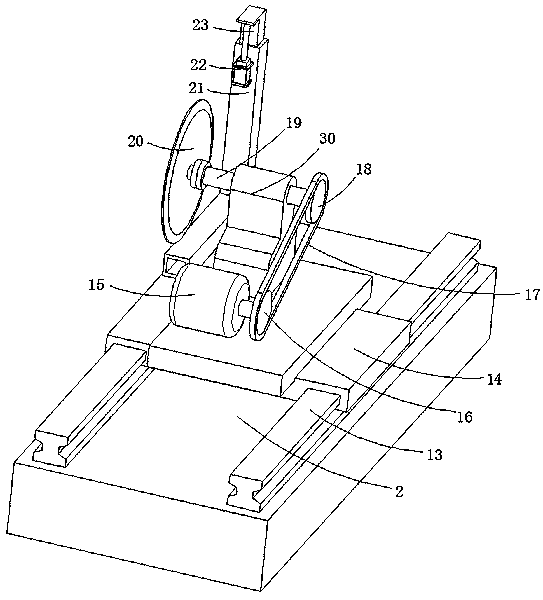

[0029] refer to Figure 1-5 , a fixed-length intelligent cutting equipment for plates, including a first support 1, a mounting plate 2 fixedly connected to the first support 1, a second support 3 fixedly connected to the mounting plate 2, and a fixed mounting plate on the top of the first support 1 The storage rack 4, the lateral side wall of the storage rack 4 is fixed with a first mounting plate 5, the first mounting plate 5 is fixed with a slide bar 6, and one end of the slide bar 6 placed inside the first mounting plate 5 is slidably connected with a first mounting plate 5. A baffle plate 7, the longitudinal side wall of the storage rack 4 is fixed with a second mounting plate 8, the second mounting plate 8 is fixed with a connecting rod 9, and the end of the connecting rod 9 away from the second mounting plate 8 is fixed with a second mounting plate 8. Baffle plate 10, the side wall of the second baffle plate 10 is fixedly provided with tape measure 12; Cutting motor 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com