Multi-channel high-efficiency pyrolysis device

A multi-channel, pyrolysis technology, applied in the direction of indirect heating carbonization, special carbonization, biofuels, etc., can solve the problems of affecting production efficiency, low thermal conductivity of biochar, low thermal conductivity of biomass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

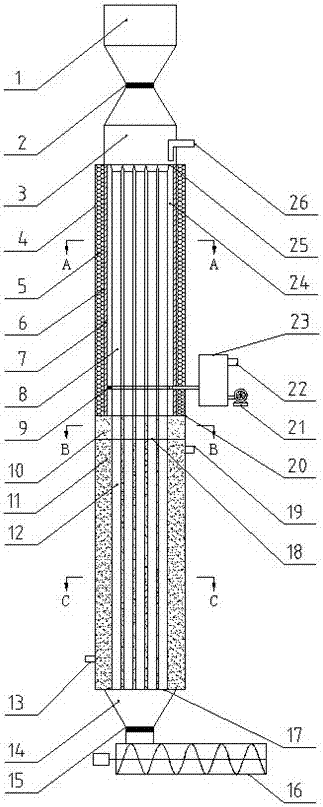

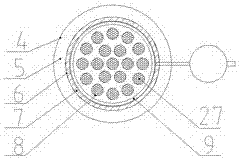

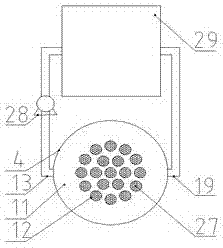

[0016] A kind of multi-channel high-efficiency pyrolysis device of the present invention is further described below with reference to accompanying drawing and the specific embodiment that the inventor provides:

[0017] figure 1 A front cross-sectional view of a multi-channel high-efficiency pyrolysis device of the present invention is given, including a feed system, a pyrolysis system, a heat insulation system, a cooling system and a charcoal discharge system;

[0018] The feed system is composed of an upper hopper 1, a No. 1 gate valve 2, a raw material settling chamber 3 and a flue gas outlet 26, wherein the upper hopper 1 and the raw material settling chamber 3 are connected by a No. 1 gate valve 2, and the raw material settling chamber 3 is fixed on On the upper plate 25 of the pyrolysis chamber, and communicated with the pyrolysis pipe 8, the flue gas outlet 26 is welded on the raw material settling chamber 3;

[0019] The pyrolysis system is composed of furnace outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com