Die-bonding adhesive pressing method and pressurizing device

A technology of pressurizing device and die-bonding glue, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the thickness of die-bonding glue and reducing the thermal resistance of the LED system, so as to reduce the thermal resistance and reduce the heat conduction path , the effect of reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

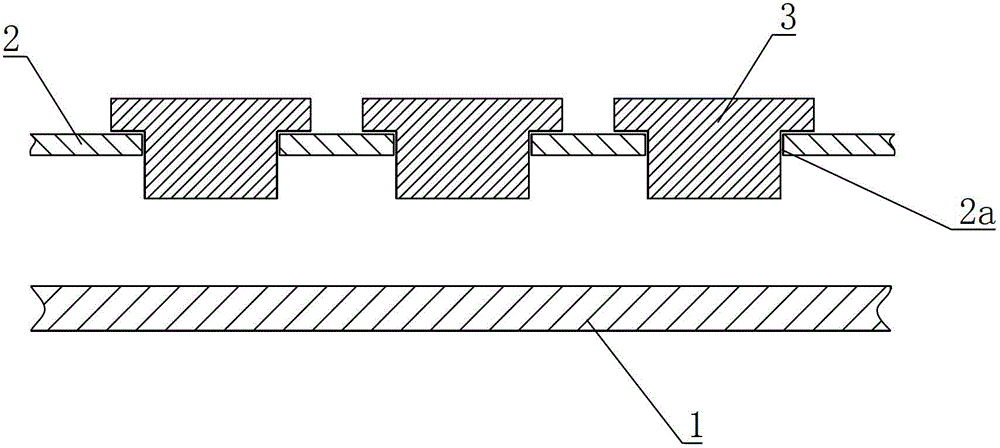

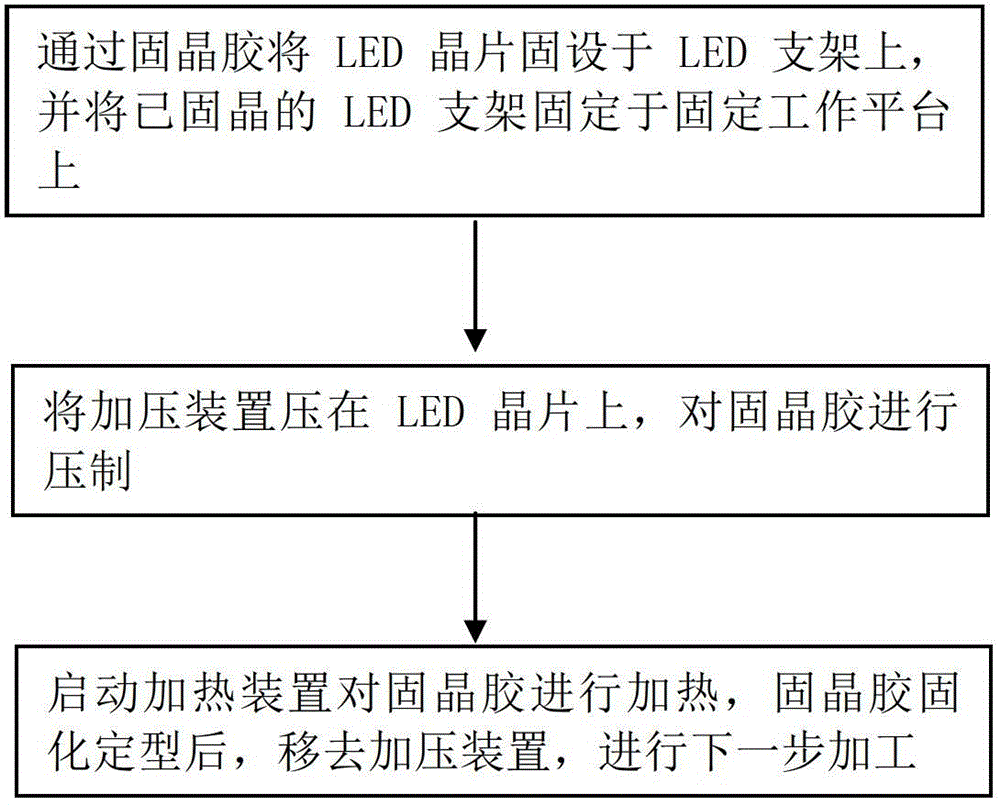

[0041] In this embodiment, an LED bracket with a cup structure is taken as an example to illustrate the present invention. Such as figure 1 As shown, the pressurizing device of this embodiment includes a fixed working platform 1, a mobile platform 2, a pressurizing block 3 and a moving control component (not shown). The fixed working platform 1 is used to place the LED bracket, and the mobile platform 2 is located above the fixed working platform 1, and the mobile platform 2 can move under the control of the mobile control part. The fixed working platform 1 and the mobile platform 2 of this embodiment are both metal plates, and the mobile platform 2 is processed with a plurality of placement holes 2a, and the placement holes 2a are distributed on the mobile platform 2 at intervals, and the placement holes 2a can be in the form of a dot matrix or a line. Arranged in an array, the position of the placement hole 2a corresponds to the position of the LED chip on the LED bracket. ...

Embodiment 2

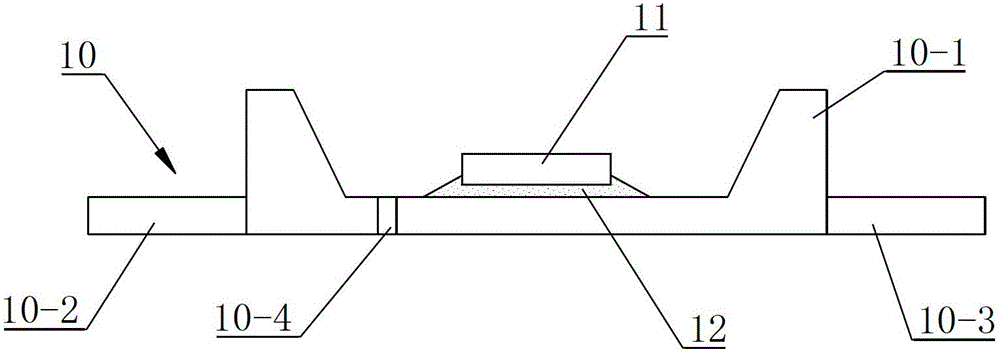

[0052] Such as Figure 8 As shown, the LED bracket of this embodiment does not have a bowl structure, and the LED bracket 10 is provided with a positive electrode 10-2 and a negative electrode 10-3, and an insulating tape 10 is placed between the positive electrode 10-2 and the negative electrode 10-3. -4 quarantined. The LED bracket 10 has a die-bonding area where the LED chip 11 is fixed, and the LED chip 11 is fixed on the LED bracket 10 through a die-bonding glue 12 .

[0053] refer to Figure 9 , the bottom surface of the mobile platform 2 of the pressurizing device in this embodiment is provided with a height limiting block 2b, and the height limiting block 2b is integrally processed and formed with the mobile platform 2. The height limiting block 2b can also be arranged on the mobile platform by welding or other connection methods. Platform 2 underside. A plurality of placement holes 2a are processed on the mobile platform 2, and the placement holes 2a are distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com