Cold-resistant drive belt primer and preparation method thereof

A cold-resistant and tape technology, applied in the field of cold-resistant transmission tape primer and its preparation, can solve problems such as unsatisfactory improvement in cold-resistant performance, and achieve the effects of improving low-temperature crystallization, accelerating peristalsis, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

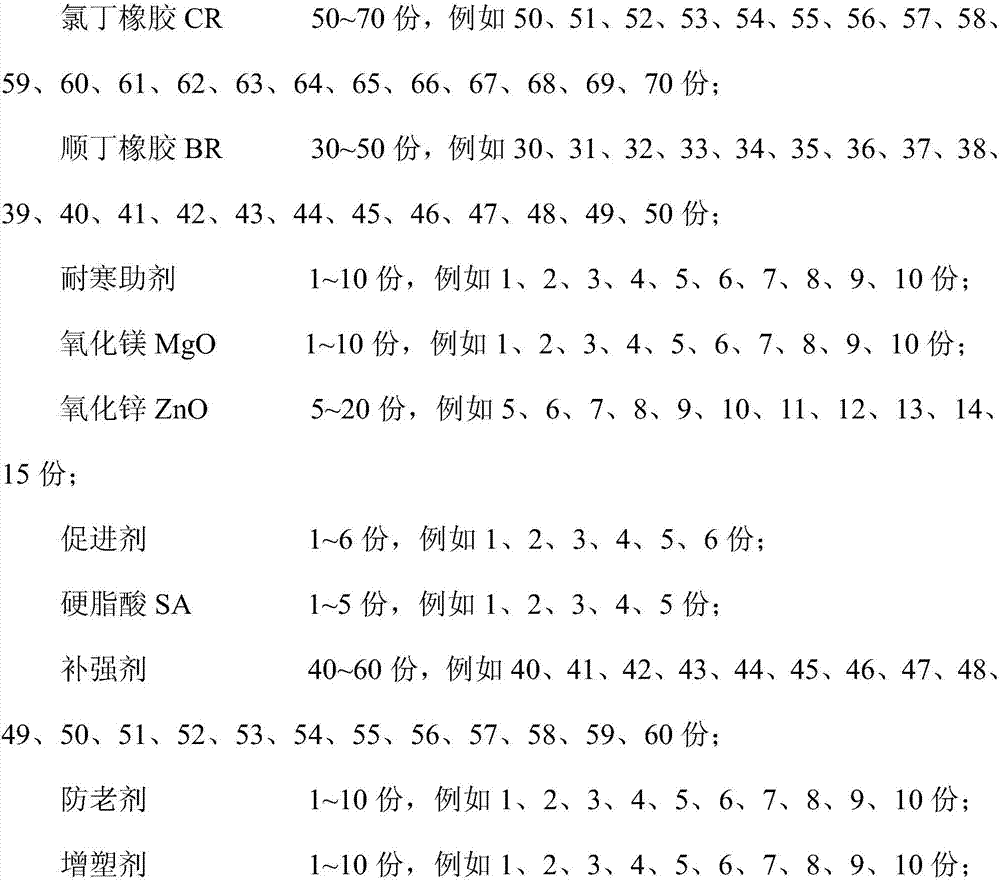

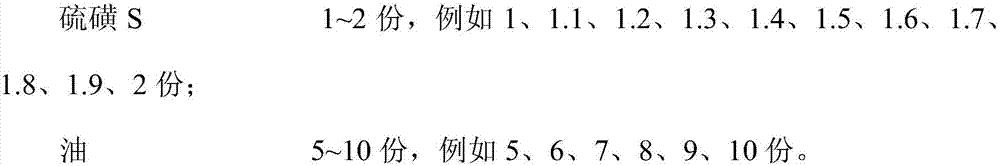

Method used

Image

Examples

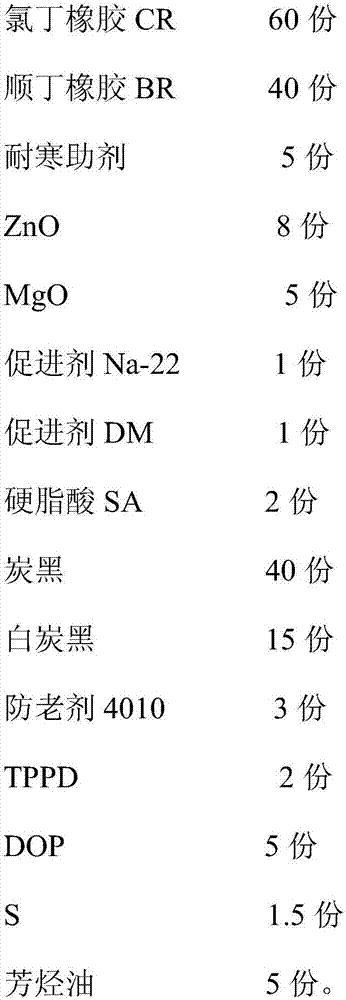

Embodiment 1

[0033] The cold-resistant transmission belt primer of the present embodiment, its preparation raw material comprises by weight: 60 parts of neoprene rubber CR, 40 parts of butadiene rubber BR, 5 parts of butyl oleate, 8 parts of ZnO, 5 parts of MgO, 1 part of Accelerator Na-22, 1 part of accelerator DM, 2 parts of stearic acid SA, 40 parts of carbon black, 15 parts of white carbon black, 3 parts of antioxidant 4010, 2 parts of TPPD, 5 parts of DOP, 2 parts of sulfur S, 5 parts Aromatic oil.

[0034] The preparation method of the above-mentioned cold-resistant transmission tape primer, comprises the steps:

[0035] 1) After mixing the neoprene CR and butadiene rubber BR of the formula amount, add it to the open mill, and roll it down after being wrapped for use;

[0036] 2) Mix the reinforcing agent and oil of the formulated amount to obtain blend A, and mix the formulated amount of magnesium oxide MgO, zinc oxide ZnO, accelerator, stearic acid SA, anti-aging agent, and plasti...

Embodiment 2

[0040] The cold-resistant transmission belt primer of the present embodiment, its preparation raw material comprises by weight: 50 parts of neoprene rubber CR, 50 parts of butadiene rubber BR, 4 parts of dibutyl sebacate, 6 parts of ZnO, 5 parts of MgO, 4 parts of accelerator Na-22, 2 parts of accelerator DM, 3 parts of stearic acid SA, 30 parts of carbon black, 20 parts of white carbon black, 2 parts of antioxidant 4010, 5 parts of TPPD, 6 parts of DOP, 2 parts of sulfur S , 7 parts aromatic oil.

[0041] The preparation method of the cold-resistant transmission tape primer of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0043] The cold-resistant transmission belt primer of the present embodiment, its preparation raw material comprises by weight: 70 parts of neoprene rubber CR, 30 parts of butadiene rubber BR, 8 parts of dibutyl sebacate, 6 parts of ZnO, 5 parts of MgO, 2 parts of accelerator Na-22, 4 parts of accelerator DM, 3 parts of stearic acid SA, 30 parts of carbon black, 10 parts of white carbon black, 4 parts of antioxidant 4010, 7 parts of TPPD, 6 parts of DOP, 1.8 parts of sulfur S , 10 parts aromatic oil.

[0044] The preparation method of the cold-resistant transmission tape primer of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com