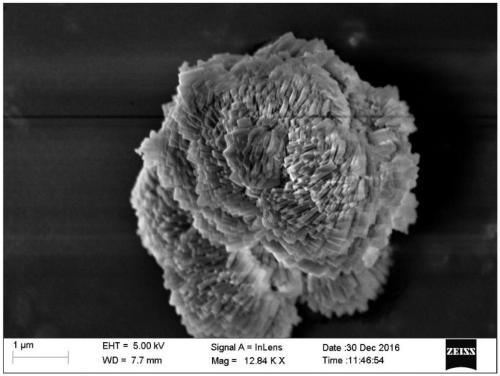

Sapo-34 hierarchical porous molecular sieve self-assembled in nanosheet spiral shape and preparation method thereof

A SAPO-34 and molecular sieve technology, applied in the field of molecular sieve research, can solve the problems of difficult separation of nano-sized molecular sieve crystals, high development and application costs, achieve good catalytic performance, facilitate large-scale industrial production, and simplify process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The molar ratio of the silicon source, aluminum source, phosphorus source oxide and organic amine template agent A, organic amine template agent B and deionized water that are finally moved into the reactor is SiO 2 :Al 2 o 3 :P 2 o 5 :A:B:H 2 O=0.6:1.0:2:4:0.2:75, A is tetraethylammonium hydroxide (35wt% aqueous solution), B is dimethyloctadecylammonium chloride (42% methanol solution).

[0037] (1) Take by weighing 11.769g tetraethylammonium hydroxide (35wt% aqueous solution), after adding 0.405g deionized water and 3.302g dimethyl octadecyl ammonium chloride methanol solution (42% methanol solution), stir 0.3 hours, a homogeneous mixture was obtained.

[0038] (2) Weigh 2.915g aluminum isopropoxide and 0.63g silica sol (containing 40wt% silicon dioxide aqueous solution), join in the above-mentioned mixed solution, stir at room temperature for 1 hour, then add 3.224g phosphoric acid (85wt% aqueous solution) dropwise , aging at room temperature for 1 hour;

[00...

Embodiment 2

[0043] The molar ratio of the silicon source, aluminum source, phosphorus source oxide and organic amine template agent A, organic amine template agent B and deionized water that are finally moved into the reactor is SiO 2 :Al 2 o 3 :P 2 o 5 :A:B:H 2 O=0.4:0.6:2:8:0.2:200, A is tetraethylammonium hydroxide (35wt% aqueous solution), B is dimethyloctadecylammonium chloride (65wt% aqueous solution).

[0044] (1) Weigh 9.50g tetraethylammonium hydroxide (35wt% aqueous solution), add 3.733g deionized water and 0.431g dimethyl octadecyl ammonium chloride (65wt% aqueous solution), and stir for 0.3 hours to obtain Homogenous mixture.

[0045] (2) Weigh 0.58g aluminum sulfate (containing Al 2 o 3 99.95wt%) and 0.24g tetraethyl orthosilicate (98wt%) were added to the above mixture, stirred at room temperature for 0.5 hours, 0.65g phosphoric acid (85wt% aqueous solution) was added dropwise, and aged at room temperature for 0.5 hours.

[0046] (3) Transfer the aged mixed solution ...

Embodiment 3

[0050] The molar ratio of the silicon source, aluminum source, phosphorus source oxide and organic amine template agent A, organic amine template agent B and deionized water that are finally moved into the reactor is SiO 2 :Al 2 o 3 :P 2 o 5 :A:B:H 2 O=0.8:1.0:6:10:0.2:300, A is tetraethylammonium hydroxide (25wt% aqueous solution) and B is dimethyloctadecylammonium chloride (60% methanol).

[0051] (1) Weigh 39.769g tetraethylammonium hydroxide (25wt% aqueous solution), add 6.214g deionized water and 11.166g dimethyl octadecyl ammonium chloride methanol solution (60% methanol), stir for 0.3 hours , to obtain a homogeneous mixture.

[0052] (2) Weigh 0.35g aluminum hydroxide and 0.12g white carbon black (containing SiO 2 90wt%), added to the above mixture, stirred at room temperature for 1 hour, added dropwise 2.646g phosphoric acid (85wt% aqueous solution), aged at room temperature for 0.8 hours.

[0053] (3) Transfer the mixed solution after aging in step (2) to a sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com