Telescopic mast and self-deploying and collapsing tower crane including the telescopic mast

A folding tower type and automatic unfolding technology, which can be used in the field of elevating cantilever cranes, telescopic masts, and tower cranes, and can solve the problems of complex design and manufacture of telescopic masts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

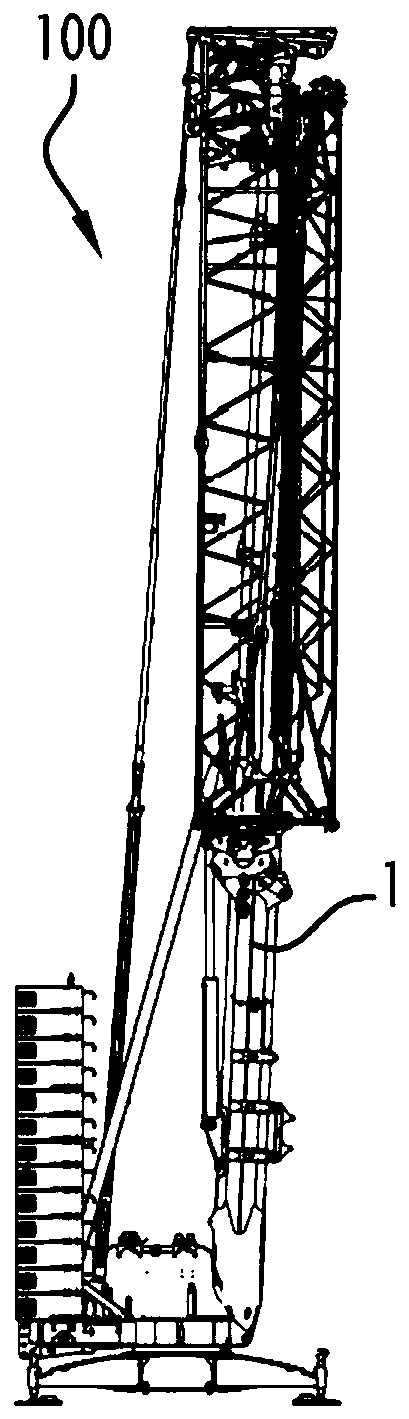

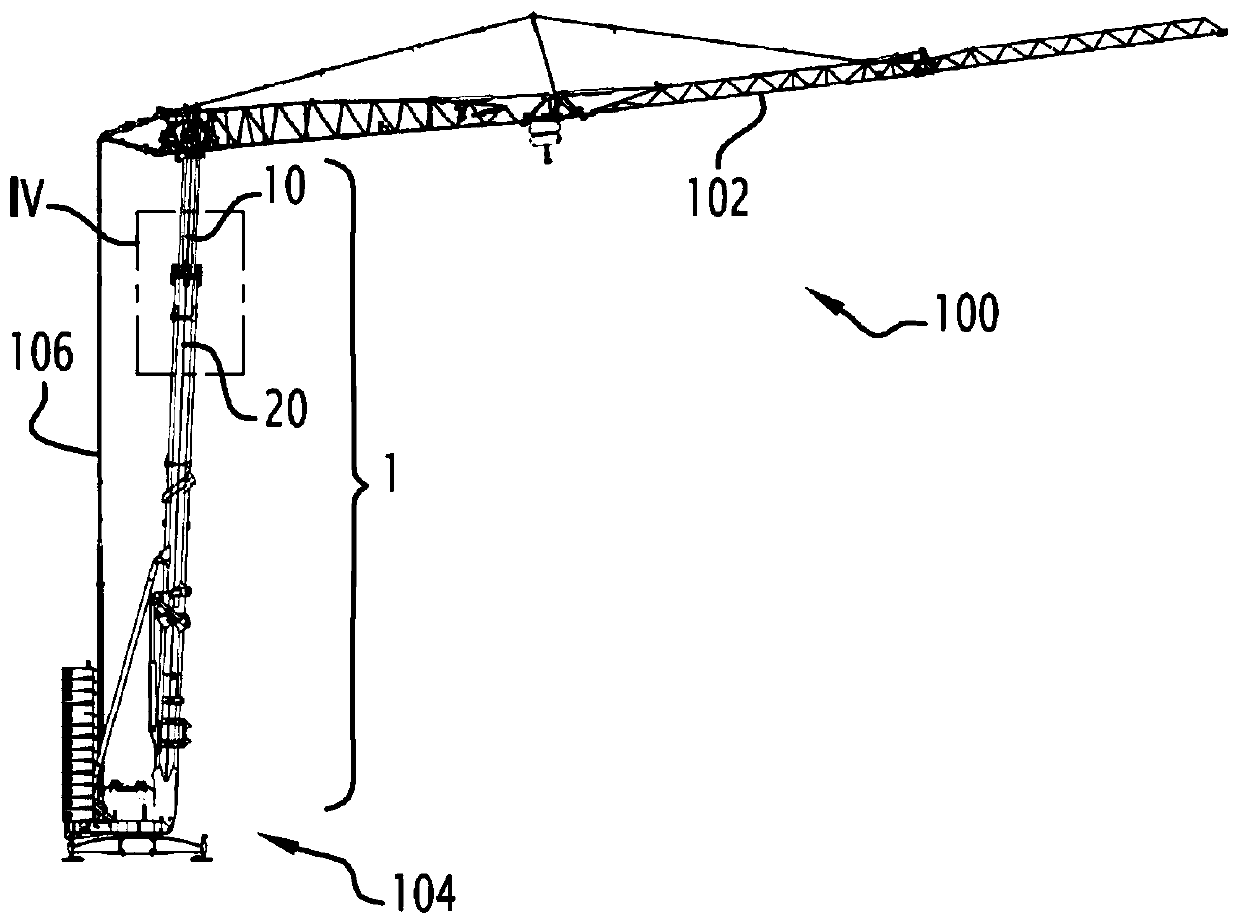

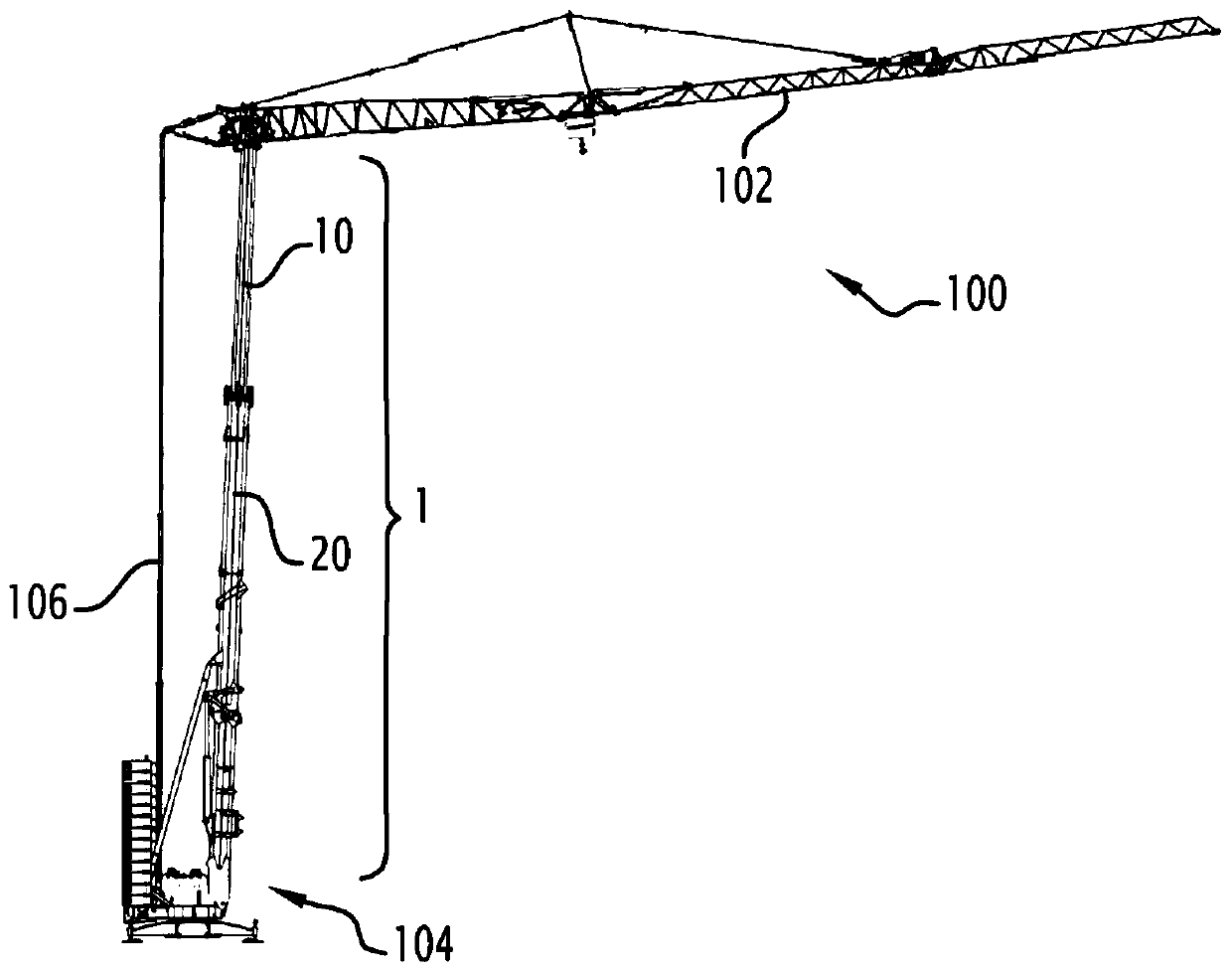

[0092] figure 1 , figure 2 with image 3 An automatically deploying and collapsing tower crane 100 comprising a jib 102 and a telescoping mast 1 is shown. Figure 4 to Figure 12 A telescoping mast 1 is shown.

[0093] The telescoping mast 1 comprises a first mast part 10 and a second mast part 20 . The first mast section 10 has a generally tubular shape consisting of flat metal sheets 12 welded and folded to form two half-shells. The second mast section 20 has a generally tubular shape consisting of flat metal sheets 22 which are welded and folded to form two half-shells.

[0094] The first mast part 10 and the second mast part 20 are configured such that the first mast part 10 can slide in the second mast part 20 along the longitudinal axis Z10 when the tower crane 100 is unfolded or folded. The cross-section of the second mast part is larger than the cross-section 20 of the first mast part 10 so that the first mast part 10 can slide in the second mast part 20 .

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com