Three-in-one self-expanding vent film sealing drop bottle structure

An exhaust membrane, three-in-one technology, applied in the field of three-in-one self-expanding exhaust membrane structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

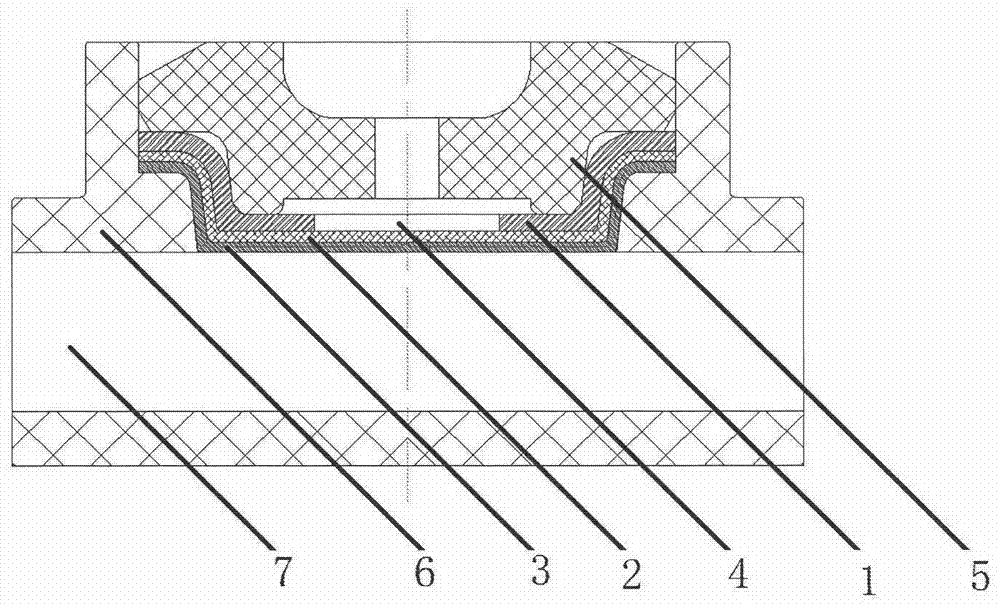

[0011] Such as figure 1 As shown, it is a kind of three-in-one self-expanding vent film sealing drop bottle structure proposed by the present invention, mainly comprising drop bottle 6, buckle 5 and three-in-one vent film, wherein the three-in-one vent film is made of It is composed of polytetrafluoroethylene membrane 3, fiber breathable support membrane 2 and mesopore elastic pad membrane 1. The order of placing and arranging the three-in-one exhaust membrane on the exhaust hole of the drop bottle is from the outside to the inside as the outermost A middle-porous elastic cushion film 1 with vent holes, a fiber breathable support film 2 in the middle layer and a polytetrafluoroethylene film 3 in the innermost layer, and a press button 5 to press the three-in-one vent film at the same time On the vent hole of the drop bottle 6, after pressing, the hollow area in the fiber breathable supporting film 2 is reinforced by the continuous elastic expansion of the mesoporous elastic pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com