Automatic leveling device for 3D printer

A 3D printer and automatic leveling technology, applied in the field of 3D printing, can solve the problems of unreasonable overall design, poor practicability, and insufficient leveling accuracy, and achieve the effect of simple structure, good stability, and reasonable overall design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

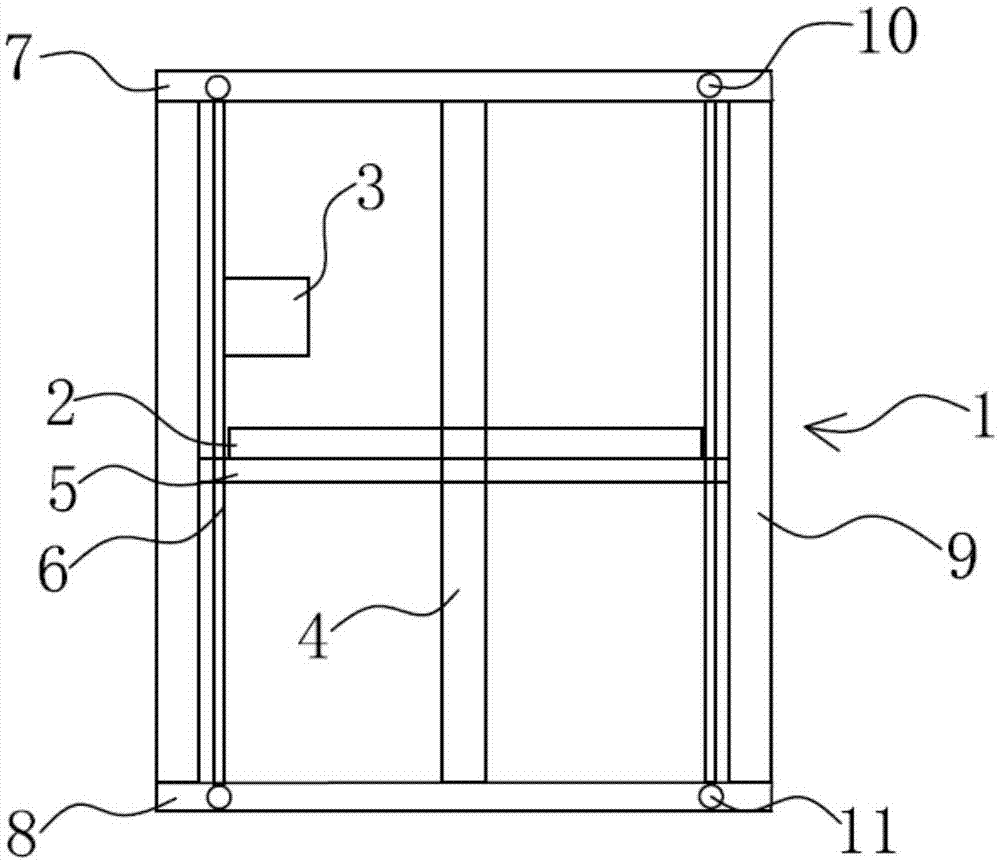

[0013] Such as figure 1 As shown, the automatic leveling device for the 3D printer includes a frame body 1, a printing platform 2 is slidably connected to the frame body 1, and a printing nozzle 3 fixed on the frame body 1 is arranged above the printing platform 2, and the lower part of the printing nozzle 3 A pressure sensor is arranged on the end face, and the pressure sensor is connected with the main control device. The middle part of the lower end of the printing platform 2 is fixedly connected with a driving rod 4, and the driving rod 4 is connected with a driving mechanism capable of driving the printing platform 2 to move longitudinally. The lower end is provided with an equilateral triangular support plate 5, and the frame body 1 is provided with a plurality of sliding rods 6, and the equilateral triangular support plate 5 is provided with sliding holes compatible with the sliding rods 6, and a sliding hole is formed between the sliding rods 6 and the frame body 1. ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com