Numerical control drilling machine locating press device for large excavator clamping plate machining

A technology of numerical control drilling machine and pressing device, which is applied to positioning devices, metal processing equipment, metal processing machinery parts, etc. The effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

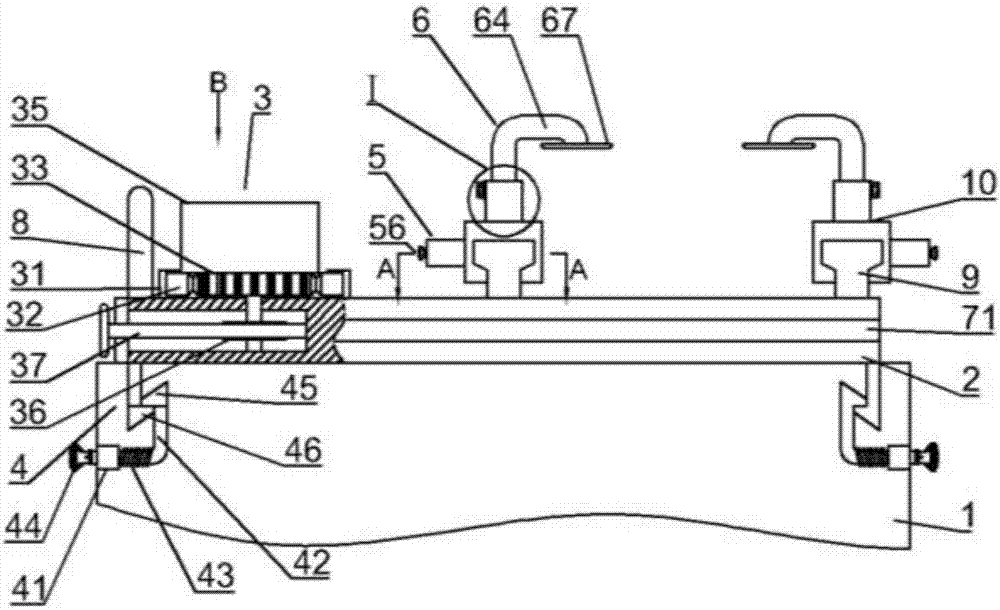

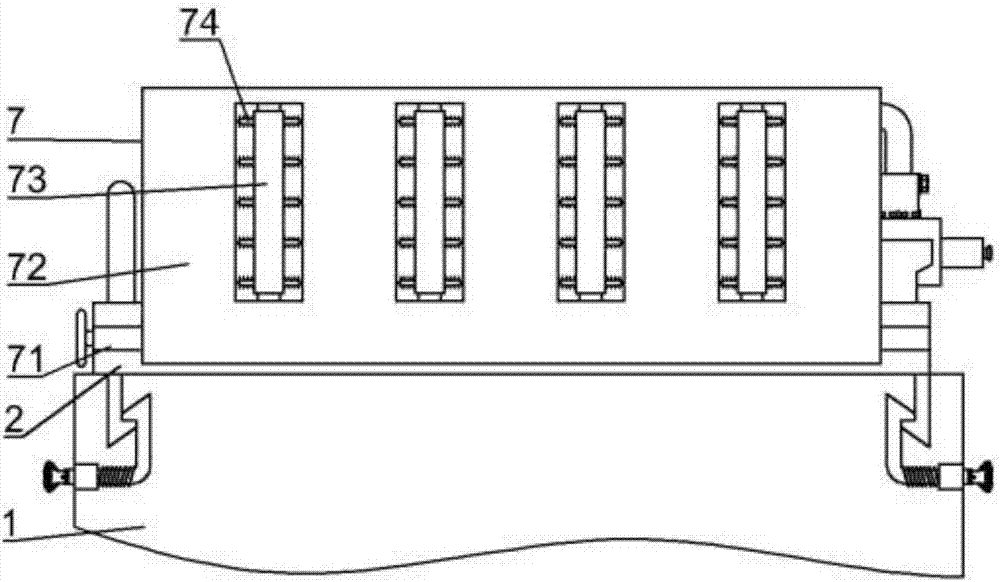

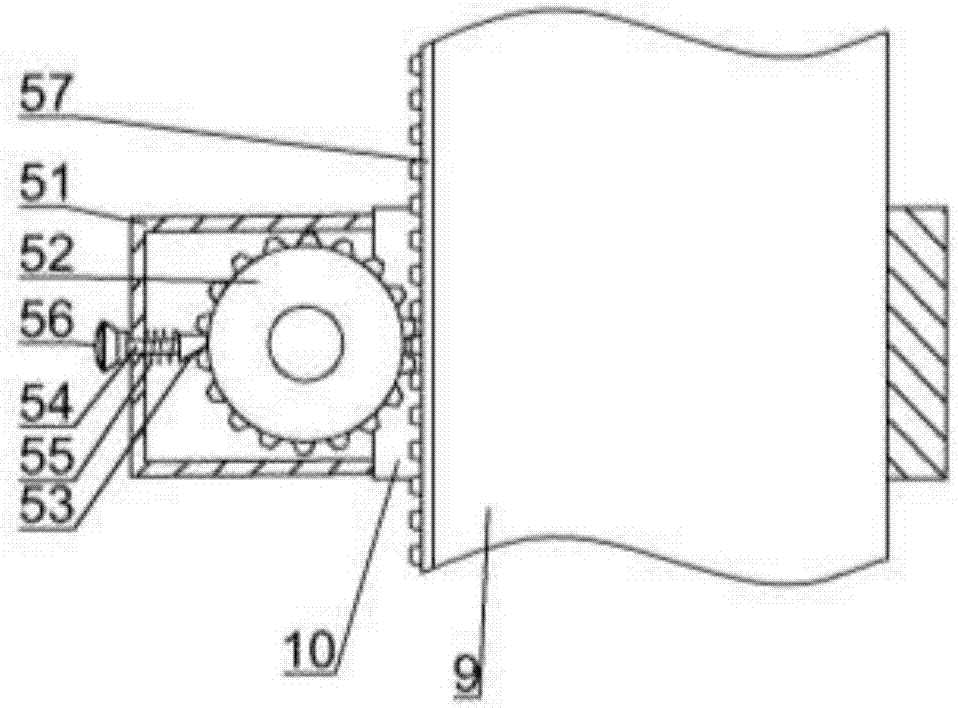

[0022] see Figure 1-5 , a CNC drilling machine positioning and pressing device for large-scale excavator splint processing, including a drilling machine platform 1, a support table 2, an X-direction positioning plate 8, a Y-direction clamping device 3, a slide rail 9, a sliding sleeve 10 and a Z downward pressure Device 6, the upper part of the drilling machine platform 1 is provided with a support platform 2, the upper left side of the support platform 2 is fixedly connected with an X-direction positioning plate 8, and the support platform 2 located on the right side of the X-direction positioning plate 8 is equipped with a Y-direction Clamping device 3, the side of the drilling machine platform 1 is fixedly equipped with a quick limiting device 4, the upper part of the drilling machine platform 1 is fixedly connected with two parallel slide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com