Adjustable clamp special for milling plane

The technology of milling plane and fixture is applied in the field of special adjustable fixture for milling plane, which can solve the problems of low manufacturing precision, large roughness value, poor clamping effect, etc., and achieve the effects of convenient operation, good clamping effect and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

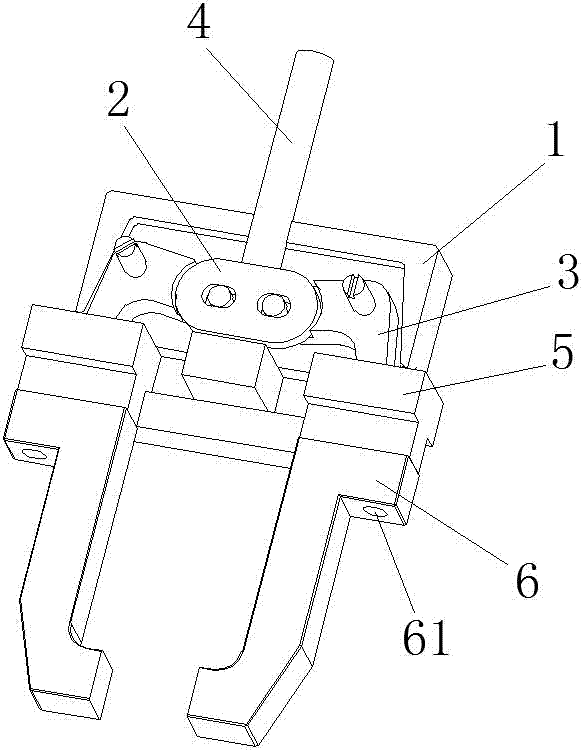

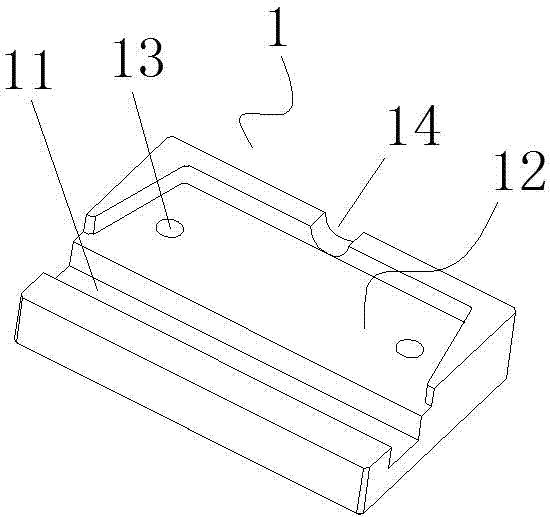

[0024] as attached figure 1 with Figure 3 ~ Figure 5 As shown, the special adjustable clamp for milling plane of the present invention provides a technical solution that includes a clamp base 1, a waist-shaped connector 2, a corner piece 3, a push handle 4, a convex slider 5, a clamping arm 6, and a bar-shaped Chute 11, trapezoidal groove 12, circular hole 13, semicircular groove 14, waist-shaped hole 21, fixing pin 22, circular corner hole 31, tightening pin 32, ball hinge 33, rotating hole 34, the first installation Holes 51 and second mounting holes 61, the upper surface of the trapezoidal groove 12 is provided with a circular hole 13 that does not penetrate the bottom surface, and two corner pieces, one left and one right, are respectively embedded in the upper surface of the trapezoidal groove 12 3. Each of the corner fittings 3 has a 90° corner structure, and a circular corner hole 31 is provided at the corner, a ball hinge 33 is provided at one end of the corner, and ...

Embodiment 2

[0026] as attached Figure 2 to Figure 5 As shown, the special adjustable clamp for milling plane of the present invention provides a technical solution that includes a clamp base 1, a waist-shaped connector 2, a corner piece 3, a push handle 4, a convex slider 5, a clamping arm 6, and a bar-shaped Chute 11, trapezoidal groove 12, circular hole 13, semicircular groove 14, waist-shaped hole 21, fixing pin 22, circular corner hole 31, tightening pin 32, ball hinge 33, rotating hole 34, the first installation Holes 51 and second mounting holes 61, the upper surface of the trapezoidal groove 12 is provided with a circular hole 13 that does not penetrate the bottom surface, and two corner pieces, one left and one right, are respectively embedded in the upper surface of the trapezoidal groove 12 3. Each of the corner fittings 3 has a 90° corner structure, and a circular corner hole 31 is provided at the corner, a ball hinge 33 is provided at one end of the corner, and a rotating hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com