Geometry of an aeraulic circuit for a hand-held vacuum

A vacuum cleaner, hand-held technology, applied in the directions of vacuum cleaners, suction filters, applications, etc., can solve the problems of high noise, load loss, reduced compactness of handheld vacuum cleaners, and undirected discharge of air flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

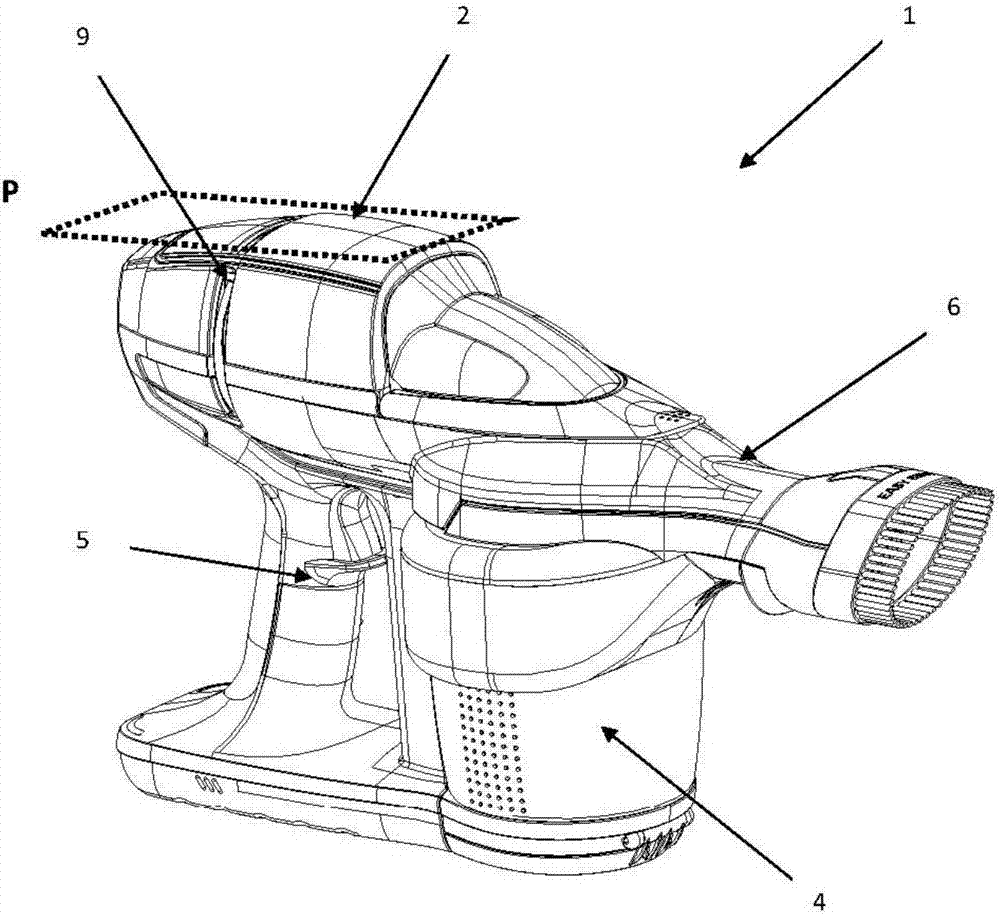

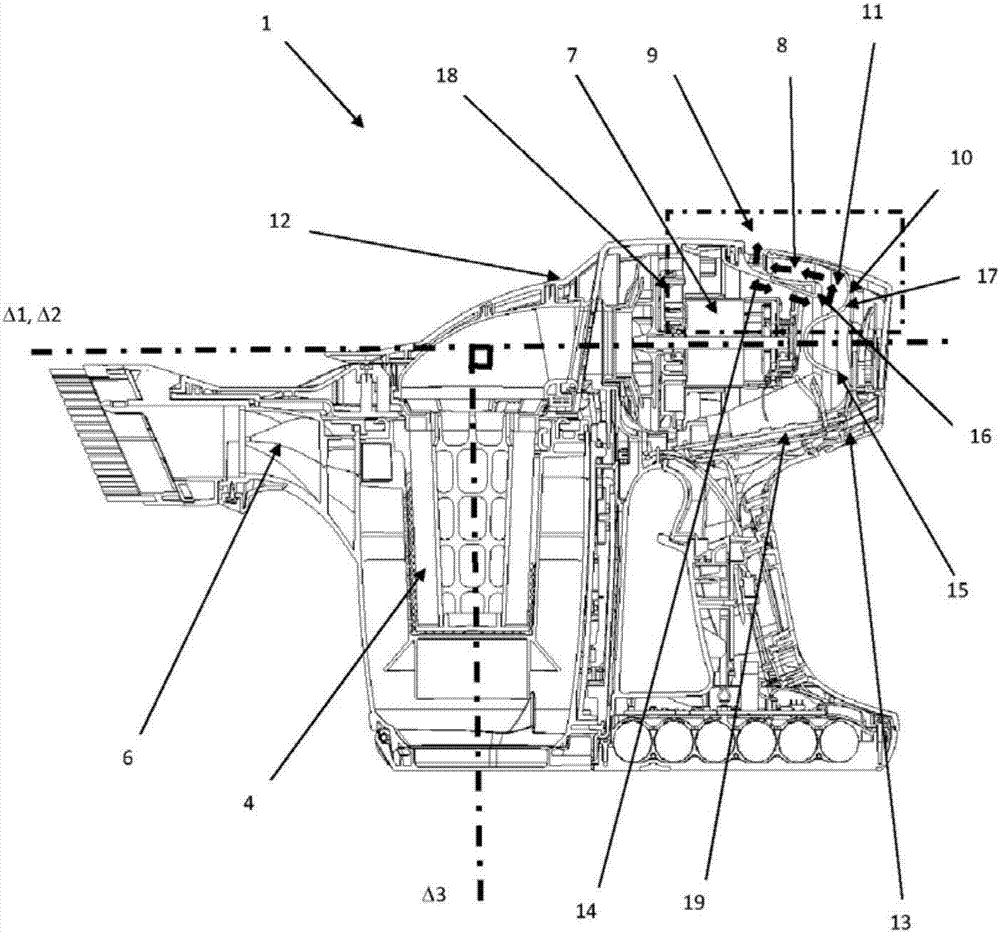

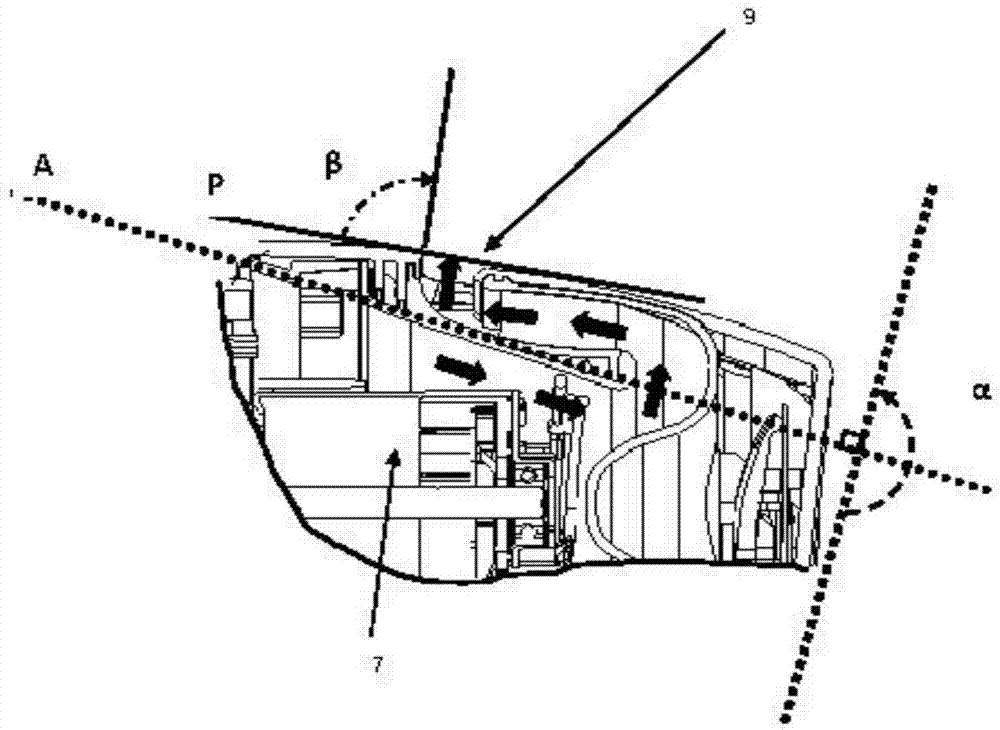

[0034] Such as figure 1 As shown, the handheld vacuum cleaner 1 is composed of a main body 2 . Said body 2 comprises at one of its ends a main suction duct 6 and at its other end an auxiliary exhaust duct 8 . The auxiliary exhaust duct 8 includes an external outlet 9 . Between these two ducts, the body 2 contains a suction mechanism 7 that generates an air flow through the main suction duct 6 and the auxiliary exhaust duct 8 . In other words, air is sucked in through the main suction duct 6 and expelled at the external outlet 9 through the auxiliary exhaust duct 8 . In an implementation variant, sound-insulating foam, not shown, can be provided in the auxiliary exhaust duct 8 in order to further reduce the velocity of the air and thus reduce the noise.

[0035] The handle 5 is fixed on the main body 2 . The grip handle allows the user to operate the handheld vacuum cleaner 1 . In the embodiment of the present invention, the handle 5 is located under the main body 2 for ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com