Berry tea frying machine

A technology for frying tea machine and berry tea, applied in the field of frying tea, can solve the problems of poor sanitary conditions, unstable quality of manual frying, threats and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

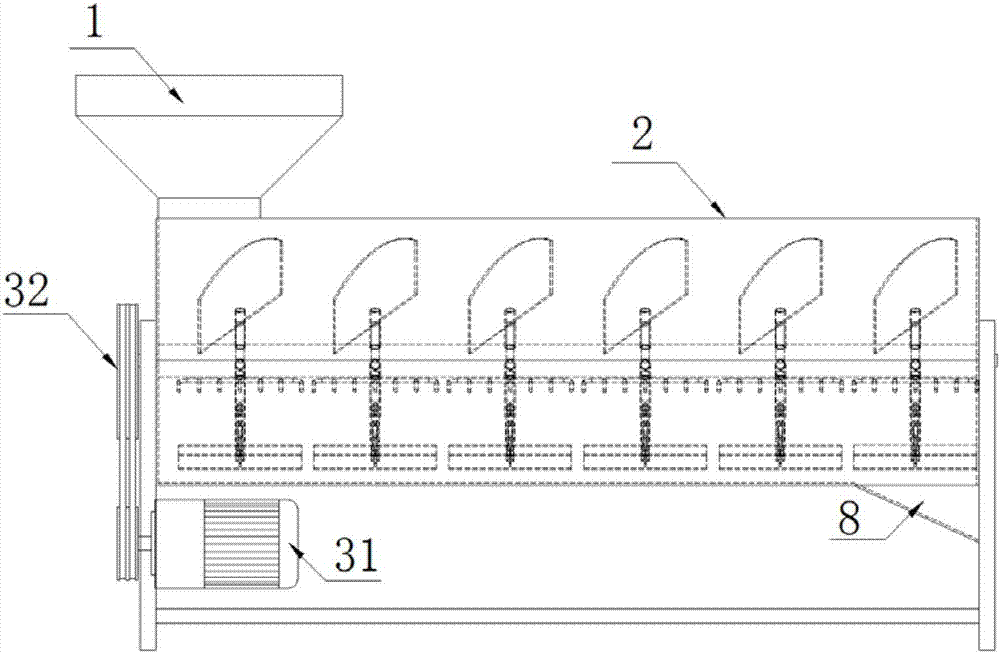

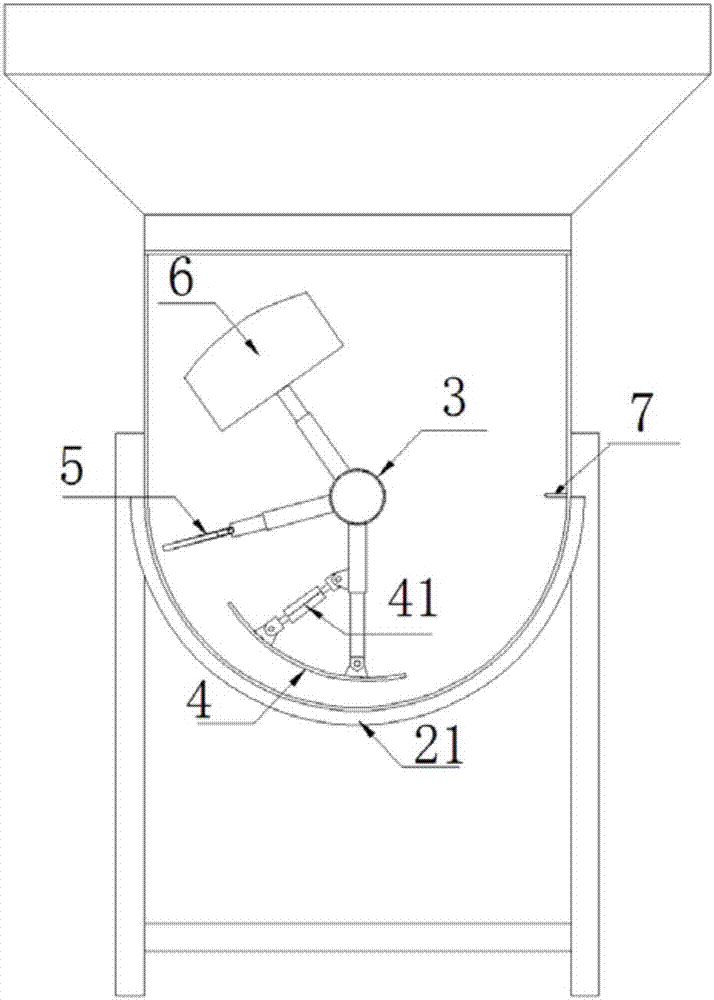

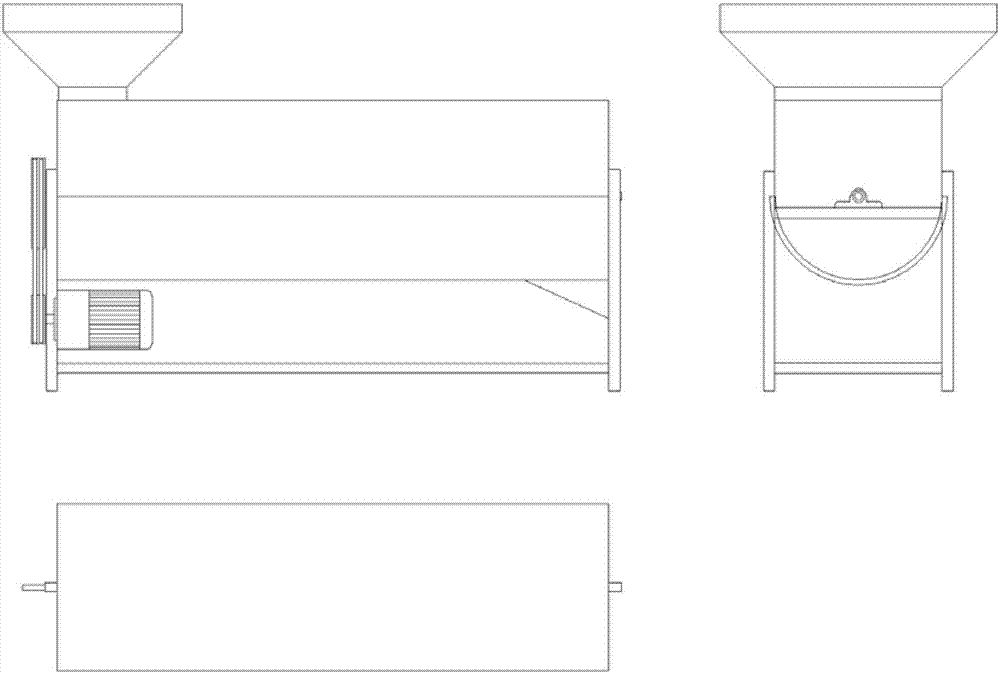

[0021] combine Figure 1-Figure 5 , a kind of raspberry tea frying machine of the present invention, comprises feeding hopper 1, pot body 2, heating element 21, tea outlet 8, and feeding hopper 1 is arranged on the head of pot body 2, and tea outlet 8 is arranged on Below the tail of the pot body 2, the heating element 21 is located at the bottom of the pot body 2; the pot body 2 is provided with a main shaft 3 and a kneading and breaking mechanism. 7. The main shaft 3 is located at the center of the pot body 2. The main shaft 3 is started by the main shaft driving motor 31 and the belt mechanism 32. The rubbing board 4, the breaking rod 5 and the tea sweeping board 6 are arranged on the main shaft 3 in sequence, and the dissolving nail 7 is vertically arranged on the On the inner wall of the pot body 2; the rubbing plate 4 is an arc-shaped plate, and the loosening nail 51 is set on the loosening rod 5, and the loosening nail 51 and the loosening nail 7 are mutually staggered....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com