Full ceramic adhesive bonding packaging technology applied to crystal resonator

A crystal resonator and packaging process technology, applied in electrical components, impedance networks, etc., can solve problems such as high production costs, increased supply risks, shortages, etc., to achieve high air tightness, avoid high production costs, adhesive good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

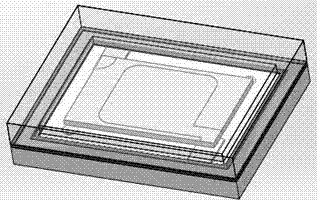

Image

Examples

Embodiment Construction

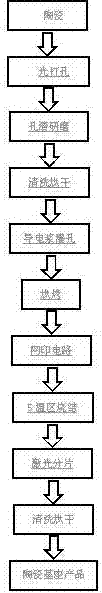

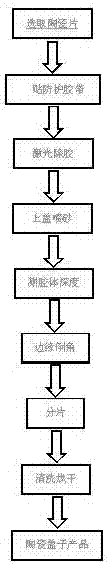

[0020] An all-ceramic adhesive bonding packaging process applied to crystal resonators, characterized in that it comprises the following steps:

[0021] 1) Production of ceramic base: select blank ceramic sheets, use a laser drilling machine to punch holes in the ceramic sheets line by line, grind the ceramic sheets with micro-through holes, and clean the holes left on the back of the ceramic sheets after laser slag, and ultrasonically clean and dry the ceramic sheet, pour conductive paste into the micro through hole of the ceramic sheet, put it in an oven to solidify, and form an electronic circuit channel, and then use screen printing to print the circuit on the front and back of the ceramic sheet , and sintered in 5 temperature zones in the sintering furnace to form metal dispensing pads and metal pads, and finally use a laser slicer to scribe the circuitized ceramic sheets, and divide the large electric polarized ceramic sheets into Small pieces, washed and dried to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com