Method for setting working voltage of silicon photomultiplier in gamma detection system

A technology of a silicon photomultiplier tube and a detection system, which is applied in the field of gamma ray detection, can solve the problems such as the setting method of the best working voltage of SiPM that has not been seen before, and achieve the effect of the best detection ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

[0027] The specific implementation steps are as follows:

[0028] 1) Put the gamma detection system in a constant temperature and humidity environment for 12-24 hours, so that the gamma radiation detector is in a stable state before detection. Generally, put the gamma radiation detector in a constant temperature and humidity environment for 18 hours.

[0029] 2) Select a gamma radiation source, the gamma radiation source has a definite energy spectrum, and there is only one all-energy peak in its energy spectrum;

[0030] The Cs137 gamma radiation source is mainly selected, because Cs137 has a definite energy spectrum, and it has only one all-energy peak at 661KeV.

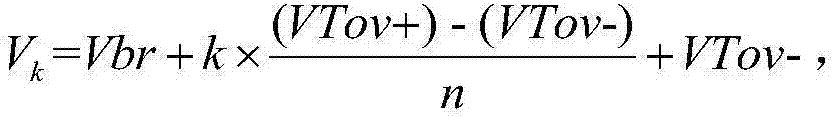

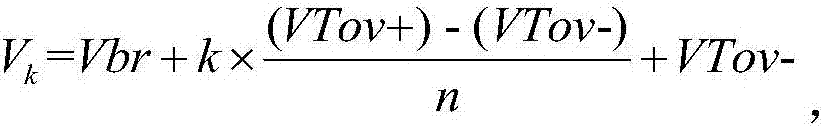

[0031] 3) Define the working voltage array V[V 0 ,V 1 ,V 2 ...V k ...V n-1 ,V n ], SNR array Y[Y 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com