Experimental system and method for gas loss measurement during coal sample crushing

A technology of crushing process and measurement method, which is applied in the direction of weighing by removing certain components, can solve the problems of large error in the loss of gas, hidden dangers of coal mine safety production safety, and influence on the accuracy of gas content measurement values, so as to improve the measurement The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

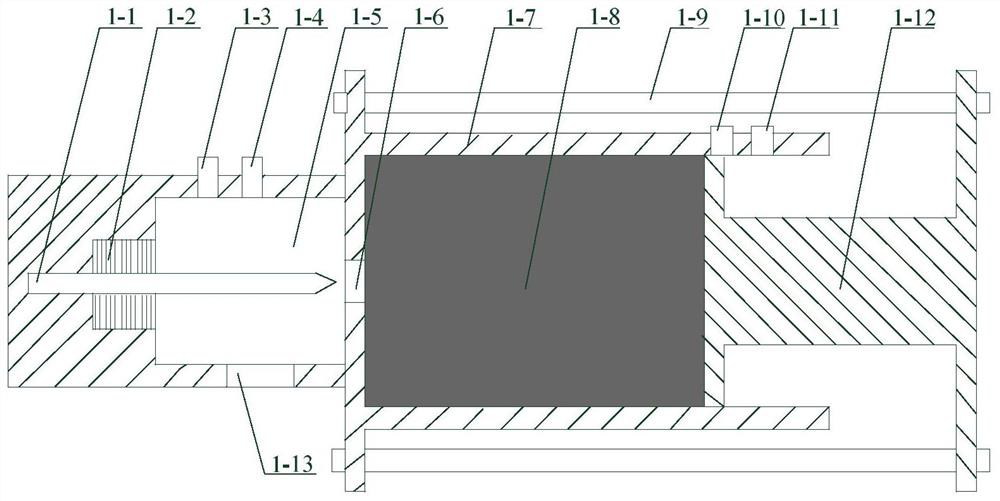

[0024] Before the experiment is carried out, the coal samples of the coal seam in the coal mine shall be collected first, the raw coal shall be crushed with a crusher, and then the dried coal samples shall be put into the vibrating sieve for screening, and shaped coal shall be prepared according to the principle of similarity and a certain proportion. Complete the assembly of the experimental system, and connect the main experimental device and other auxiliary systems according to the composition of the experimental system: the linear motor 1-2 is connected to the linear motor control system, the gas outlet A (1-3) of the crushed coal bunker and the gas outlet of the coal bunker ( 1-11) are all connected to the vacuum system, the gas outlet B (1-4) of the crushed coal bunker is connected to the digital mass flow meter and the gas collection system in turn, and the gas charging port (1-10) of the coal bunker is connected to the gas loading system. The pressure loading push rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com