Vortex ejector

An injector and vortex technology, applied in the field of auto parts, can solve the problems of poor reduction treatment effect of automobile exhaust gas, lower utilization rate of urea aqueous solution, poor mixing of exhaust gas, etc., and achieve good spray atomization quality, simple structure, and precise spraying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

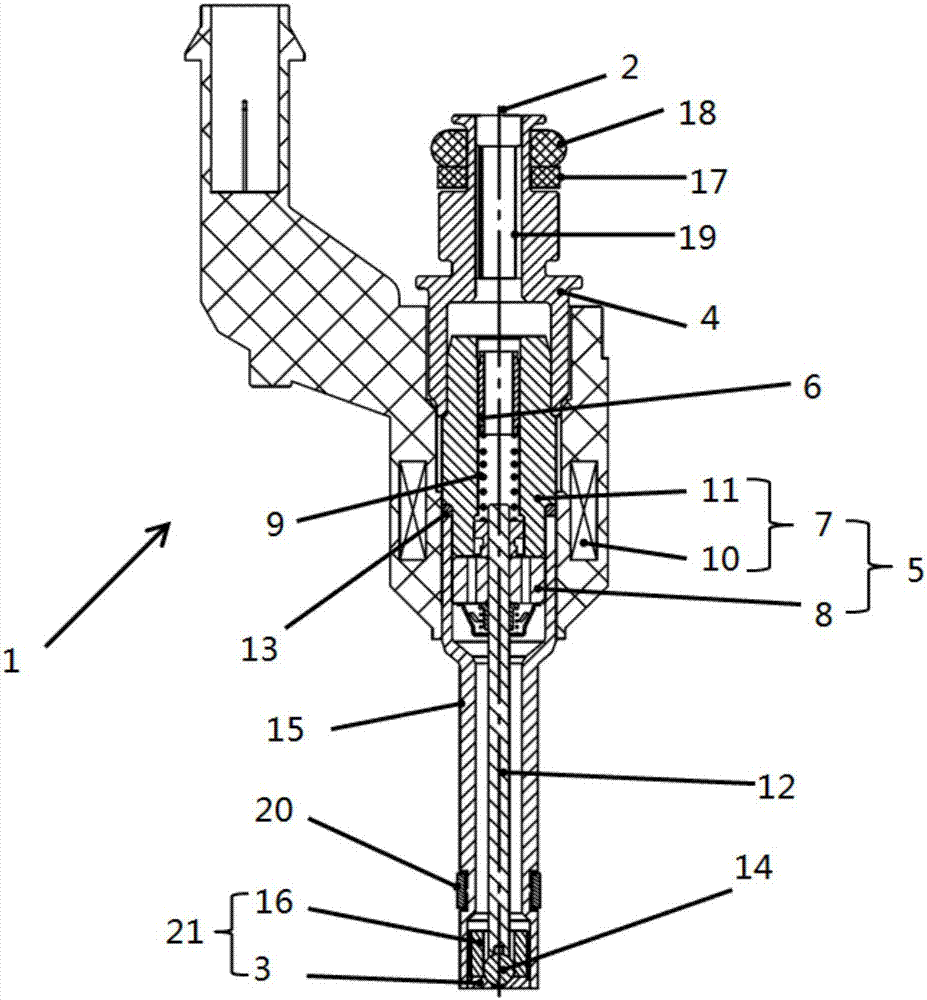

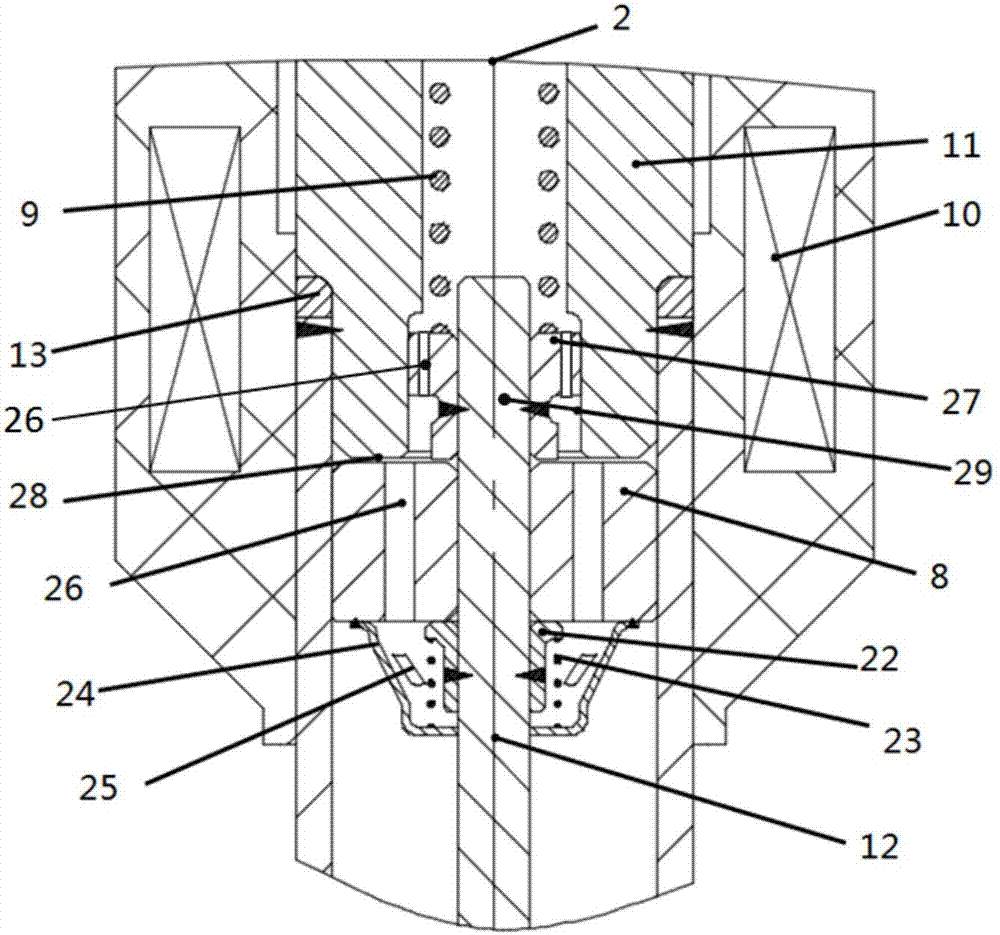

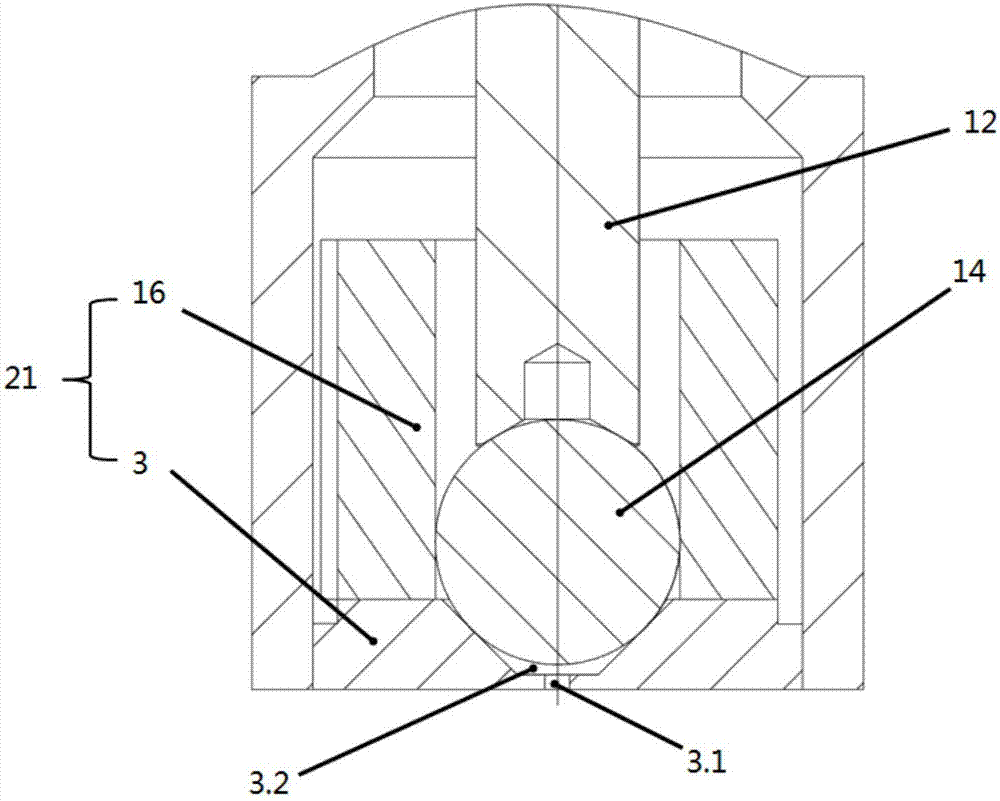

[0028] A vortex injector is characterized in that it is mainly composed of a tubular casing, an injection switch valve 21 , a ball valve 14 , a valve stem 12 , a solenoid valve assembly 5 and a main spring 9 .

[0029] Such as figure 1 Shown: 1 represents the entire swirl injector, axis 2 is its axis of symmetry. The valve seat 3 can eject the liquid to form a hollow spray. The upper body 4 of the vortex injector shell, the fixed iron core 11, the lower body 15 of the vortex injector shell and the adjusting gasket 13 are annularly welded together to form the shell of the vortex injector 1, and a ball valve 14 and a valve stem 12 are arranged in the liquid passage in the pipe. , the main spring 9 and the damping assembly preventing the valve stem from bouncing. The upper part of the vortex injector 1 is equipped with a solenoid valve assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com