Pickling solution and application of weight loss analysis to detect corrosion of metal materials

A technology of metal materials and pickling liquid, which is applied in the direction of removing certain components and weighing, can solve the problems of disproportionation reaction of monovalent copper ions, affect the accuracy of weight loss analysis, and troublesome use of washing liquid, so as to reduce disproportionation Reaction, reduced substrate loss, weak cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The pickling solution for weight loss analysis and detection of corrosion of metal materials is: Measure 10 ml of concentrated hydrochloric acid and 100 ml of water, pour them into a 250 ml beaker, and stir evenly with a glass rod. Weigh 40 grams of hexamethylenetetramine, add it into the mixed hydrochloric acid and water mixture, and stir with a glass rod until the hexamethylenetetramine is completely dissolved. Use a calibrated pH meter to measure the pH value of the pickling solution, and the average value of the three measured pH values is 5.41.

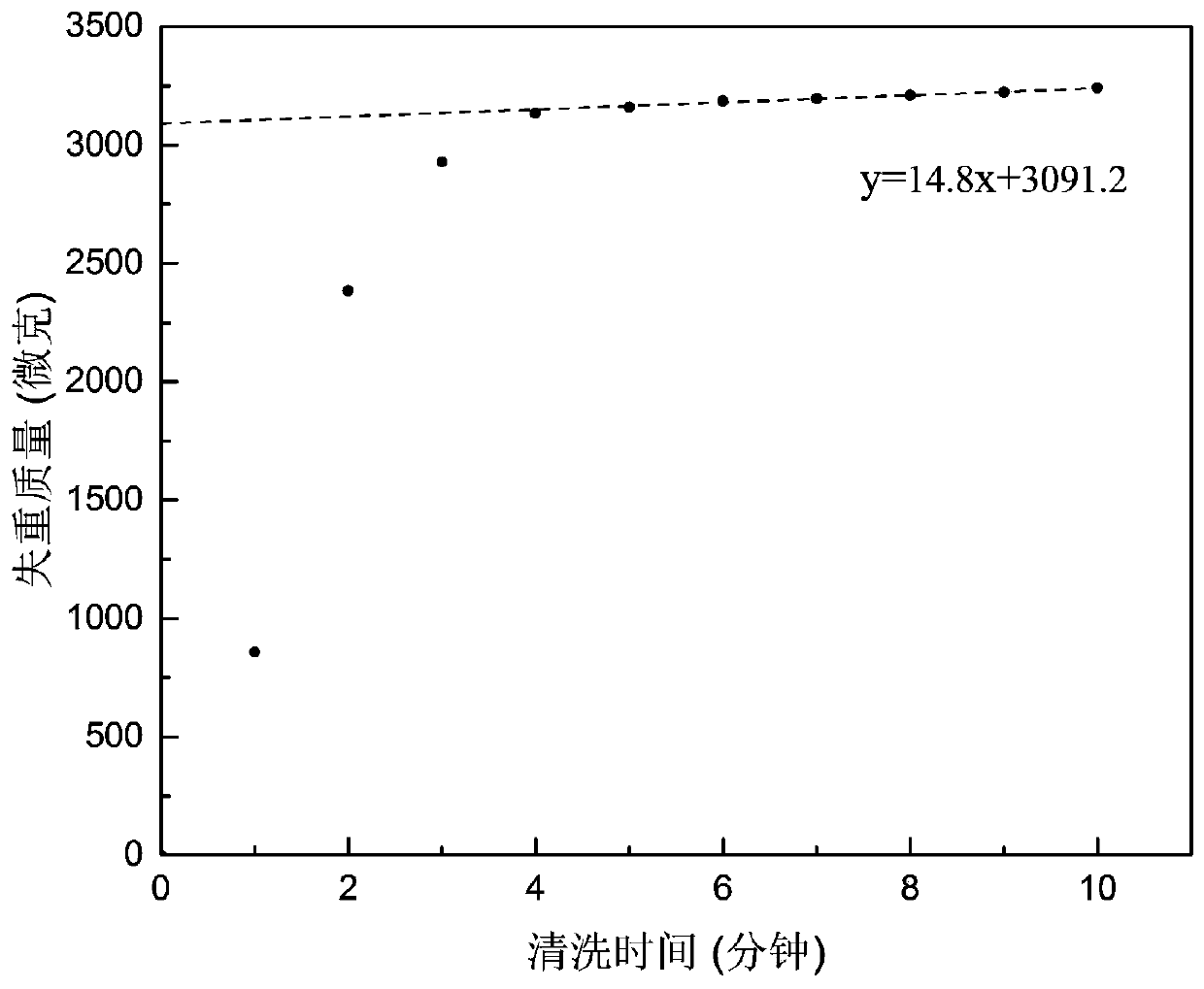

[0024] The pickling solution obtained above was used for weight loss analysis and detection. Prepare 200 ml of tap water, 200 ml of deionized water and 50 ml of absolute ethanol for cleaning the pickled sample. Put the pure copper strip rust sample with a size of 50×10×1mm into the prepared pickling solution, put the beaker containing the pickling solution into the ultrasonic instrument, turn on the ultrasonic, and time...

Embodiment 2

[0027] Take 5 pieces of parallel pure copper strip rust samples with a size of 50×10×1 mm, and use the hydrochloric acid-hexamethylenetetramine-water pickling solution used in Example 1 to perform circular cleaning again. Wherein, the cleaning process is the same as in Example 1, and the weight loss data processing is also the same as in Example 1, and it can be seen from the data that the cleaning solution reduces the problem of low weight loss data caused by the disproportionation of monovalent copper ions, and the sample is accurately obtained. Corrosion weight loss data, while ensuring a small metal substrate loss.

[0028] After completing embodiment 1, the pH value of the pickling solution was measured to be 5.41, which was the same as before the pickling solution was used. Table 1 lists the weight loss mass (mass of cuprous oxide) of each parallel test piece calculated after repeated use of the pickling solution to clean the parallel test pieces and the pH value of the ...

Embodiment 3

[0032] The pickling solution for weight loss analysis and detection of corrosion of metal materials is: Measure 10 ml of concentrated hydrochloric acid and 100 ml of water, pour them into a 250 ml beaker, and stir evenly with a glass rod. Weigh 20 grams of hexamethylenetetramine, add it into the mixed hydrochloric acid and water mixture, and stir with a glass rod until the hexamethylenetetramine is completely dissolved. Use a calibrated pH meter to measure the pH value of the pickling solution, and the average value of the three measured pH values is 4.48.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com