Anti-permeation rain-print-resistant anti-pollution wall finish paint and preparation method thereof

A technology of anti-penetration and wall paint, applied in the field of coatings, can solve the problems of anti-penetration, anti-rain marks and poor anti-pollution performance, and achieve the goal of improving anti-rain mark performance, reducing the degree of rain marks, and excellent stain resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

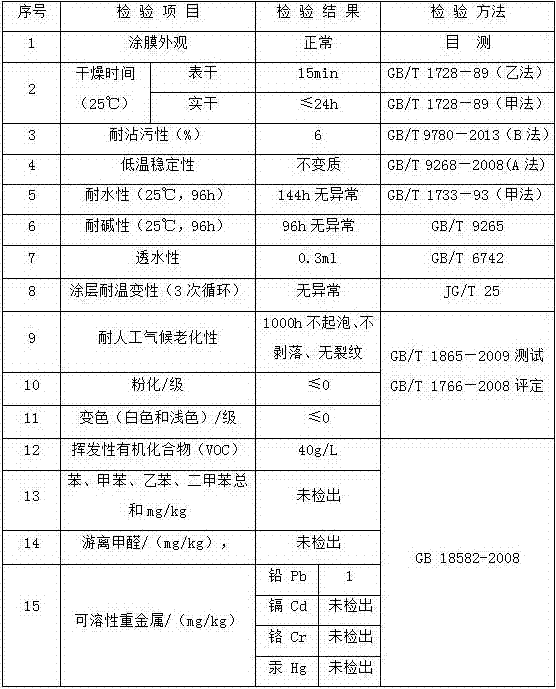

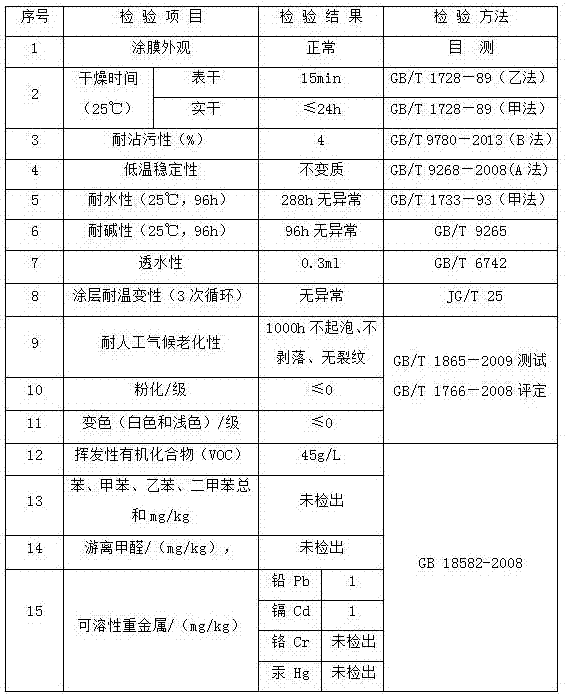

Image

Examples

Embodiment 1

[0047] The raw materials of the anti-penetration anti-rain mark anti-fouling wall paint provided in this embodiment are:

[0048] Nano-polyacrylate emulsion 50%, organic-inorganic composite material 15%, nano-silicon emulsion 5%, nano-titanium dioxide 8%, hydrophobic modified dispersant 0.5%, fluorocarbon surfactant 0.8%; film-forming aid 1.7%, Antifreeze 0.5%, PH value stabilizer 0.1%, defoamer 0.6%, thickener 0.3%, antiseptic bactericide 0.3%; the rest is deionized water.

[0049] The preparation method of the anti-penetration anti-rain mark anti-fouling wall paint provided by the embodiment of the present invention is:

[0050] Mix deionized water, fluorocarbon surfactants, dispersants, antiseptics, PH value stabilizers, and defoamers, and stir evenly through a certain shear; then add nano-titanium dioxide, organic-inorganic composite materials and shear at high speed to According to the specified fineness, add nano-polyacrylate emulsion and nano-silicon emulsion in turn u...

Embodiment 2

[0052] The raw materials of the anti-penetration anti-rain mark anti-fouling wall paint provided in this embodiment are:

[0053] Nano-polyacrylate emulsion 45%, organic-inorganic composite material 20%, nano-silicon emulsion 5%, nano-titanium dioxide 8%, hydrophobic modified dispersant 0.4%, fluorocarbon surfactant 0.6%; film-forming aid 1.5%, Antifreeze 0.5%, PH value stabilizer 0.2%, defoamer 0.4%, thickener 0.3%, antiseptic bactericide 0.3%; the rest is deionized water.

[0054] The preparation method of the anti-penetration anti-rain mark anti-fouling wall paint provided by the embodiment of the present invention is:

[0055] Mix deionized water, fluorocarbon surfactants, dispersants, antiseptics, PH value stabilizers, and defoamers, and stir evenly through a certain shear; then add nano-titanium dioxide, organic-inorganic composite materials and shear at high speed to According to the specified fineness, add nano-polyacrylate emulsion and nano-silicon emulsion in turn u...

Embodiment 3

[0057] The raw materials of the anti-penetration anti-rain mark anti-fouling wall paint provided in this embodiment are:

[0058] Nano-polyacrylate emulsion 40%, organic-inorganic composite material 20%, nano-silicon emulsion 10%, nano-titanium dioxide 10%, hydrophobic modified dispersant 0.5%, fluorocarbon surfactant 0.6%; film-forming aid 1.6%, 0.5% antifreeze, 0.15% PH value stabilizer, 0.5% defoamer, 0.4% thickener, 0.3% antiseptic and bactericide; the rest is deionized water.

[0059] The preparation method of the anti-penetration anti-rain mark anti-fouling wall paint provided by the embodiment of the present invention is:

[0060] Mix deionized water, fluorocarbon surfactants, dispersants, antiseptics, PH value stabilizers, and defoamers, and stir evenly through a certain shear; then add nano-titanium dioxide, organic-inorganic composite materials and shear at high speed to According to the specified fineness, add nano-polyacrylate emulsion and nano-silicon emulsion in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com