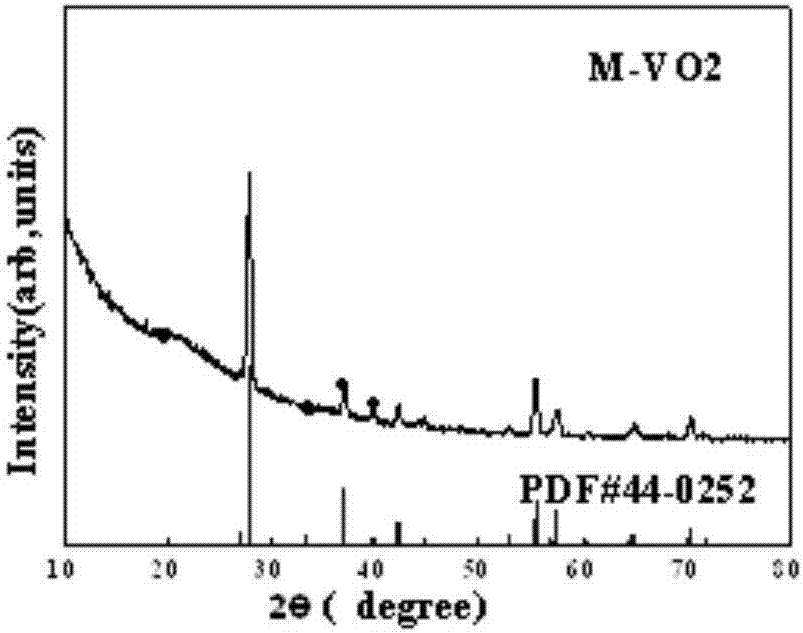

Preparation method of environmentally-friendly thermochromic vanadium dioxide film

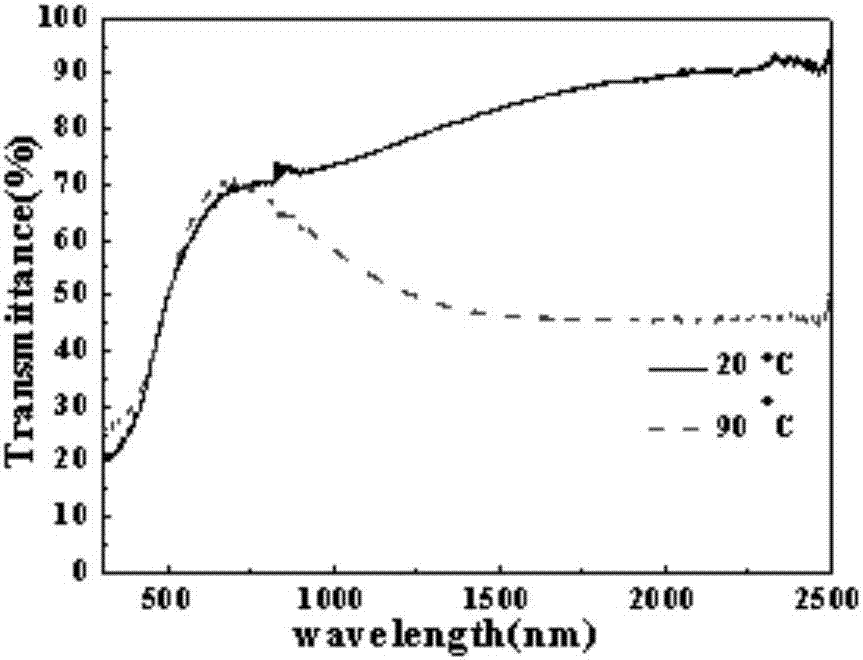

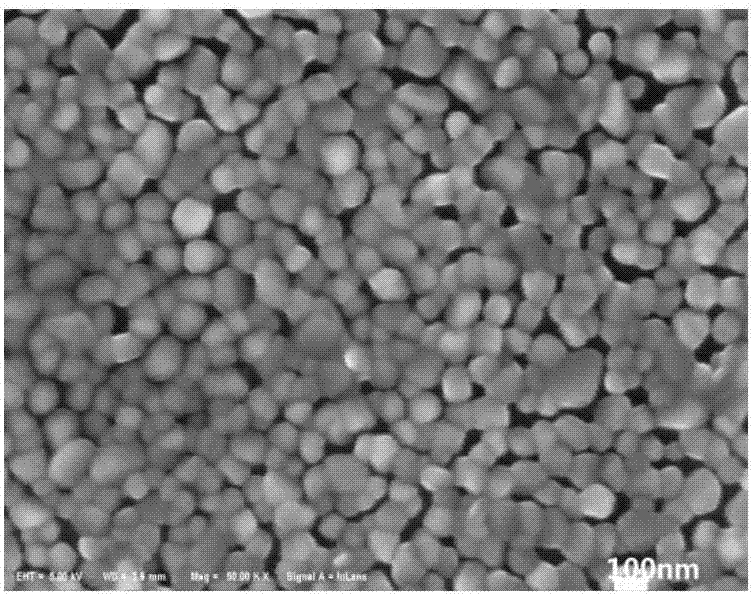

A vanadium dioxide and thermochromic technology, which is applied in the field of preparation of environment-friendly thermochromic vanadium dioxide thin films, can solve the problems of low visible light transmittance, complicated process, influence visual effects and the like, and achieves visible light transmission. High rate, small surface roughness, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The thermochromic vanadium dioxide thin film is prepared by an environmentally friendly method, and the steps are as follows:

[0028] 1) First, use detergent solution, water, and absolute ethanol to ultrasonically clean the quartz glass substrate (2.5mm×2.5mm) for 10-20min to remove dirt, grease and other impurities on the surface, and place it in absolute ethanol stored in storage for use;

[0029] 2) Configure the precursor sol: add 0.5g vanadium pentoxide to 30mL deionized water, and then add 0.484g ascorbic acid after stirring (the molar ratio of vanadium pentoxide to ascorbic acid is 1:1), and stir at room temperature for 30min to obtain a uniform solution. When the solution turns dark brown-green at room temperature, add 2 mL of concentrated hydrochloric acid, then heat and stir in a water bath at 60°C until the solution is blue and transparent, then add 3.0 g of polyvinylpyrrolidone, and stir at room temperature to obtain the precursor Sol;

[0030] 3) Prepara...

Embodiment 2

[0033] The thermochromic vanadium dioxide thin film is prepared by an environmentally friendly method, and the steps are as follows:

[0034] 1) First, ultrasonically clean the quartz glass substrate (2.5mm×2.5mm) for 10-20min with detergent solution, water, and absolute ethanol to remove dirt, grease and other impurities on the surface, and place it in absolute ethanol stored in storage for use;

[0035] 2) Prepare precursor sol: add 3.0g vanadium pentoxide to 30mL deionized water, then add 1.453g ascorbic acid after stirring, stir at room temperature for 30min to obtain a uniform solution, and add 4mL when the solution turns dark brown-green at room temperature Concentrated hydrochloric acid, then heated and stirred in a water bath at 40°C until the solution was blue and transparent, then added 1.175g of polyvinylpyrrolidone, and stirred at room temperature to obtain a precursor sol;

[0036]3) Preparation of vanadium dioxide thin film: drop the precursor sol obtained in st...

Embodiment 3

[0040] The thermochromic vanadium dioxide thin film is prepared by an environmentally friendly method, and the steps are as follows:

[0041] 1) First, use detergent solution, water, and absolute ethanol to ultrasonically clean the quartz glass substrate (2.5mm×2.5mm) for 10-20min to remove dirt, grease and other impurities on the surface, and place it in absolute ethanol stored in storage for use;

[0042] 2) Prepare the precursor sol: add 1.0g vanadium pentoxide to 30mL deionized water, then add 0.484g ascorbic acid after stirring, stir at room temperature for 30min to obtain a uniform solution, and add 12mL when the solution turns dark brown-green at room temperature Concentrated hydrochloric acid, then heated and stirred in a water bath at 60°C until the solution was blue and transparent, then added 2.378g of polyvinylpyrrolidone, and stirred at room temperature to obtain a precursor sol;

[0043] 3) Preparation of vanadium dioxide thin film: drop the precursor sol obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com