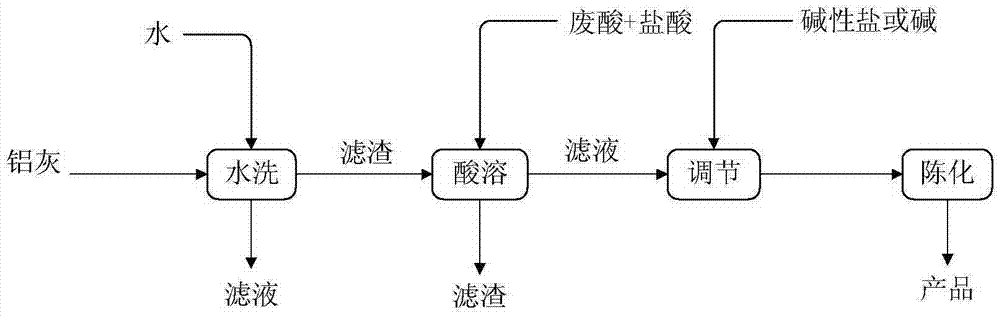

Method for producing aluminum polychlorid water purifying agent from waste hydrochloric acid and aluminum ash

A technology of polyaluminum chloride and waste hydrochloric acid, applied in the fields of aluminum chloride, chemical instruments and methods, aluminum halide, etc., can solve problems such as aluminum ash pollution, achieve the effect of ensuring stability and promoting rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add a certain amount of industrial hydrochloric acid to the waste hydrochloric acid solution until the hydrogen ion concentration is 3g / l, wash the aluminum ash three times with tap water, and put the aluminum ash into the prepared waste hydrochloric acid solution according to the liquid-solid ratio of 10ml / g , reacted at 80°C for 1.5h, and separated the liquid and solid after the reaction to obtain an aluminum-containing solution; added calcium carbonate to the aluminum-containing solution in two batches, and carried out a polymerization reaction until all the calcium carbonate was dissolved and the pH value of the solution was 3 ~5; then aged in a water bath at 60°C for 10 hours to obtain a polyaluminum chloride water purifier.

[0038] The aluminum oxide content of the prepared polyaluminum chloride water purifying agent is 12.3%, and the basicity is 78.4%.

Embodiment 2

[0040] Add a certain amount of industrial hydrochloric acid to the hydrogen ion concentration in the waste hydrochloric acid solution to be 3g / l, wash the aluminum ash with tap water 3 times, and put the aluminum ash into the prepared waste acid at a liquid-solid ratio of 20ml / g. React at 80°C for 1.5 hours. After the reaction is completed, liquid-solid separation is carried out to obtain an aluminum-containing solution; calcium carbonate is added to the aluminum-containing solution in two batches, and the polymerization reaction is carried out until the calcium carbonate is completely dissolved and the pH value of the solution is 3~ 5; then aging in a water bath at 60°C for 10 hours to obtain a polyaluminum chloride water purifier.

[0041] The prepared polyaluminum chloride water purifying agent has an alumina content of 10% and a basicity of 62.8%.

Embodiment 3

[0043] Add a certain amount of industrial hydrochloric acid to the hydrogen ion concentration in the waste hydrochloric acid solution to be 3g / l, wash the aluminum ash with tap water 3 times, and put the aluminum ash into the prepared waste acid at a liquid-solid ratio of 10ml / g. React at 90°C for 1.5 hours, and carry out liquid-solid separation at the end of the reaction to obtain an aluminum-containing solution; add calcium carbonate to the aluminum-containing solution in two batches, and perform a polymerization reaction until all the calcium carbonate is dissolved and the pH value of the solution is 3~ 5; then aging in a water bath at 60°C for 10 hours to obtain a polyaluminum chloride water purifier.

[0044] The aluminum oxide content of the prepared polyaluminum chloride water purifier is 10.1%, and the basicity is 88%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com