Thin film encapsulation structure and preparation method of organic electroluminescent device

An electroluminescent device and thin-film packaging technology, which is applied in the manufacturing of organic semiconductor devices, electric solid-state devices, and semiconductor/solid-state devices, etc. The effect of reducing the loss of light reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

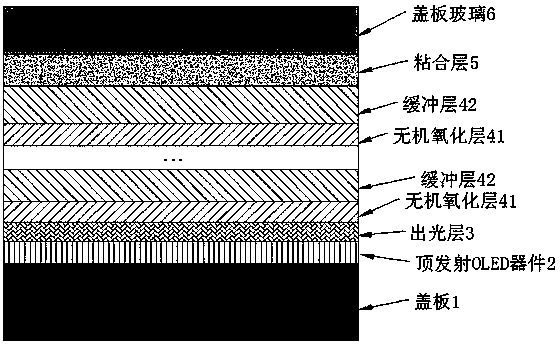

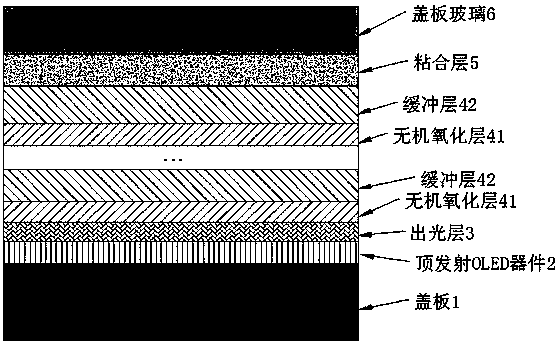

[0032] Such as figure 1 Shown:

[0033] A thin-film encapsulation structure of an organic electroluminescence device, which is prepared through the following steps:

[0034] (1) A top-emitting OLED device 2 is formed on a glass substrate 1 by a thermal evaporation method.

[0035] (2) Prepare the light layer 3 on the cathode of the OLED device by thermal evaporation.

[0036] (3) In step (2), the thickness of the light exit layer is 30nm, the refractive index is 1.65, and the material is SiO.

[0037] (4) ALD is used to deposit an inorganic oxide layer 41 on the light-extracting layer 3 .

[0038] (5) In step (4), the thickness of the inorganic oxide layer 41 is 24nm, and the structure is Al2O3(4nm) / TiO2(4nm) / Al2O3(4nm) / TiO2(4nm) / Al2O3(4nm) / TiO2(4nm) / .

[0039] (6) A buffer layer 42 is spin-coated on the inorganic oxide layer 41 .

[0040] (7) In step (6), the buffer layer 42 is polysiloxane with a thickness of 1 μm.

[0041] (8) Steps (4) and (6) are repeated three ti...

Embodiment 2

[0046] Such as figure 1 Shown:

[0047] A thin film encapsulation structure of an organic electroluminescent device, which is prepared by the following method:

[0048] (1) A top-emitting OLED device 2 is formed on a silicon substrate 1 by a thermal evaporation method.

[0049] (2) Prepare the light layer 3 on the cathode of the OLED device by thermal evaporation.

[0050] (3) In step (2), the light emitting layer is composed of SiO and SiOx. Wherein, SiO has a thickness of 20 nm and a refractive index of 1.67; SiOx has a thickness of 20 nm and a refractive index of 1.6.

[0051] (4) ALD is used to deposit an inorganic oxide layer 41 on the light-extracting layer 3 .

[0052] (5) In step (4), the thickness of the inorganic oxide layer 41 is 30nm, and the material is Al 2 o 3 , the refractive index is 1.57.

[0053] (6) A buffer layer 42 is spin-coated on the inorganic oxide layer 41 .

[0054] (7) In step (6), the buffer layer 42 is polysiloxane with a thickness of 600...

Embodiment 3

[0060] Such as figure 1 Shown:

[0061] A thin-film encapsulation structure of an organic electroluminescence device, which is prepared through the following steps:

[0062] (1) A top-emitting OLED device 2 is formed on a glass substrate 1 by a thermal evaporation method.

[0063] (2) Prepare the light layer 3 on the cathode of the OLED device by thermal evaporation.

[0064] (3) In step (2), the thickness of the light emitting layer is 40nm, the refractive index is 1.65, and the material is SiO.

[0065] (4) ALD is used to deposit an inorganic oxide layer 41 on the light-extracting layer 3 .

[0066](5) In step (4), the thickness of the inorganic oxide layer 41 is 50nm, and the structure is Al2O3(5nm) / ZrO2(5nm) / Al2O3(5nm) / ZrO2(5nm) / Al2O3(5nm) / ZrO2(5nm) / Al2O3(5nm) / ZrO2(5nm) / Al2O3(5nm) / ZrO2(5nm) / .

[0067] (6) A layer of buffer layer 42 is scraped on the inorganic oxide layer 41 using a scraper coating technique.

[0068] (7) In step (6), the buffer layer 42 is polysilox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com