High-pressure large-flow quick opening valve

A large flow, high pressure technology, applied in the direction of valve lift, valve details, valve devices, etc., can solve the problems of poor reliability, slow response, complex structure, etc., and achieve the effect of compact structure, adjustable speed, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]First of all, it should be noted that the orientation words such as front, back, left, right, up, and down in the present invention are only descriptions for the convenience of those skilled in the art to understand according to the accompanying drawings, and are not technical solutions of the present invention. The limitations made should be understood by those skilled in the art according to actual usage conditions.

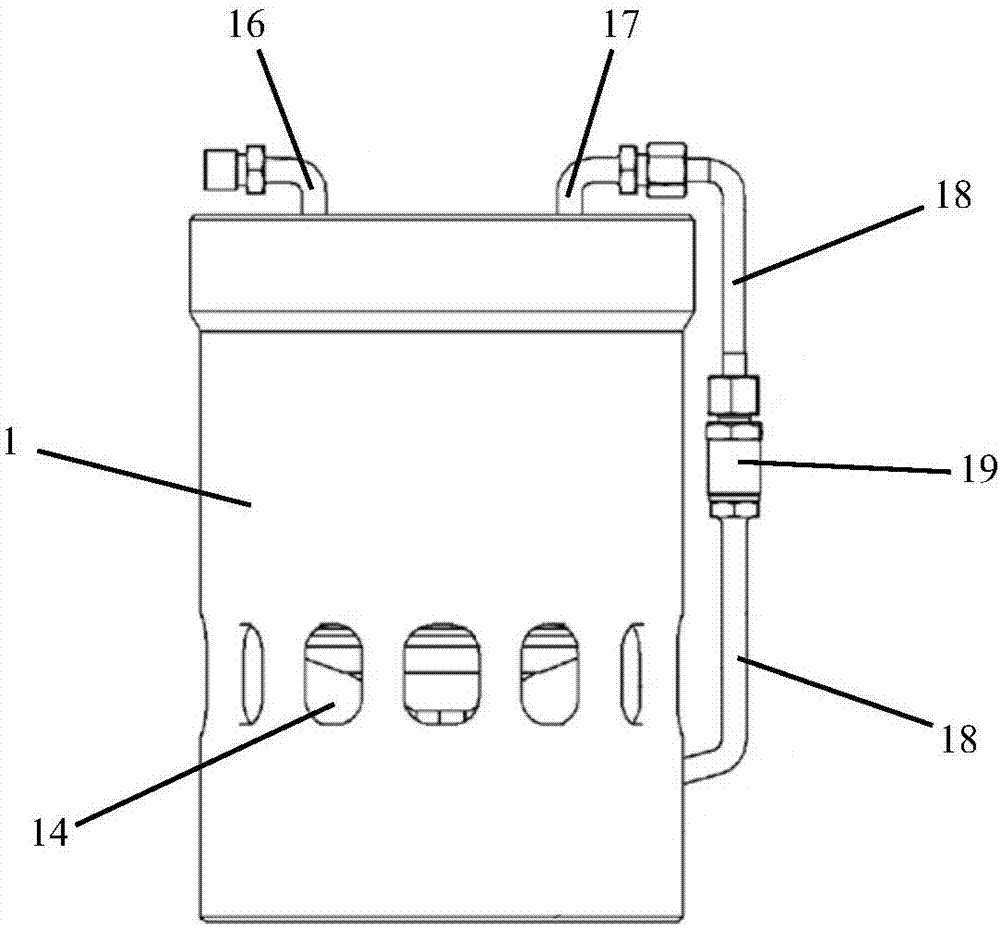

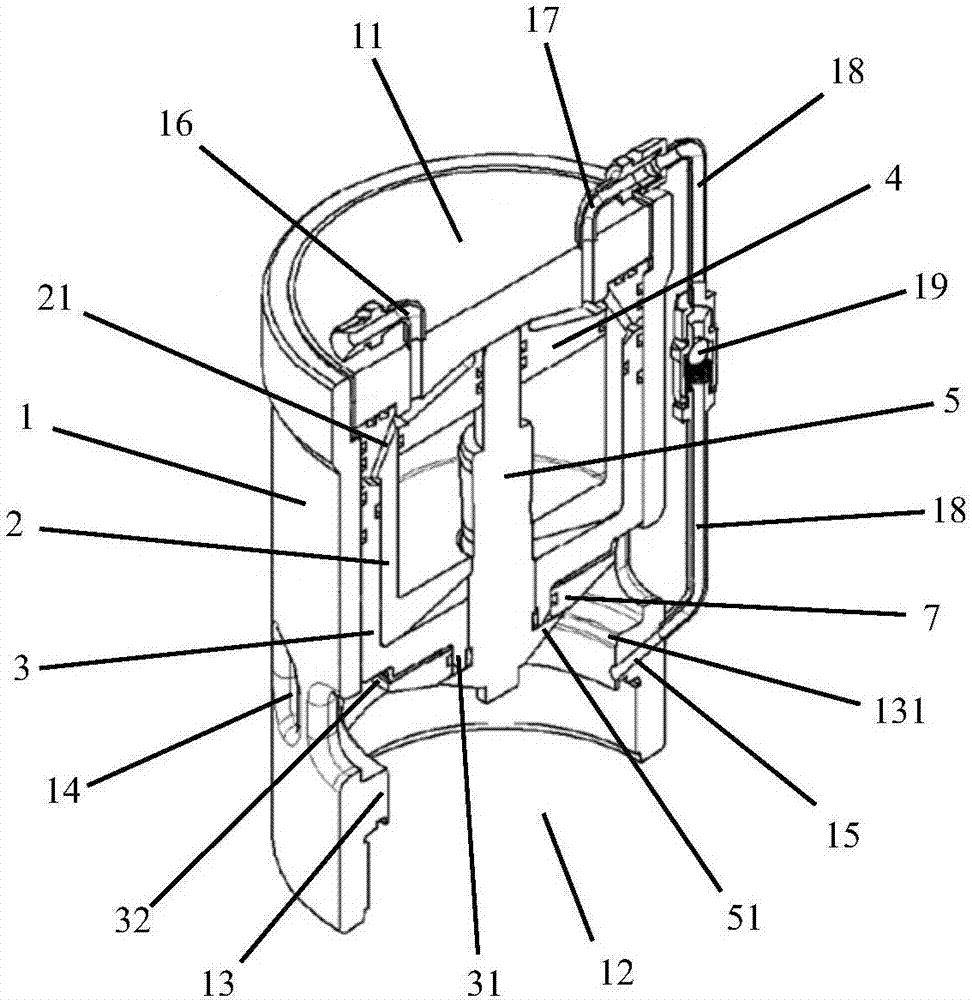

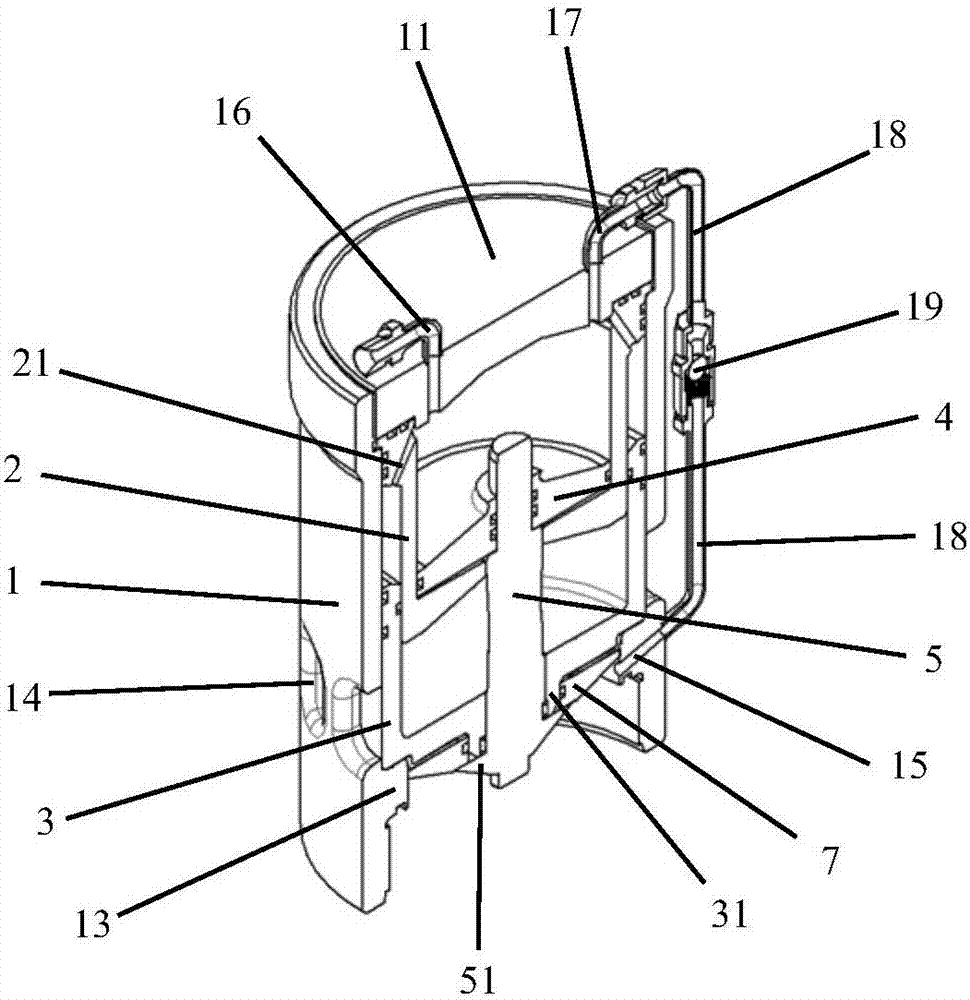

[0021] Such as Figure 1 to Figure 4 Shown is a specific embodiment of a high-pressure and large-flow quick-opening valve of the present invention, including a valve body 1 , a throttle sleeve 2 , a main valve 3 , an air barrier sleeve 4 and a throttle rod 5 . The valve body 1 is tubular and provided with an upper end cover 11, and the lower end of the valve body 1 is provided with an air circuit connection port 12, which can adopt various connection methods such as threads or flanges. The throttle sleeve 2 is provided with a peripheral wall and a bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com