Electronic expansion valve and valve core thereof

A technology of electronic expansion valve and spool, which is applied to the parts in contact between the valve element and the valve seat, the lifting valve, the valve device, etc., which can solve the problems of failure of the function of adjusting the flow rate, increased noise, and no change in the flow rate. Achieve the effects of increasing the effective flow area, reducing the area of the vortex area, and increasing the mass flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The core of the present invention is to provide an electronic expansion valve and its valve core. The structural design of the valve core can reduce the area of the vortex area formed at the bottom of the valve core when the opening is large, increase the effective flow area of the fluid, and reduce the The effect of flow regulation.

[0041] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] For ease of understanding and brevity of description, the electronic expansion valve and its valve core will be described together below, and the beneficial effects will not be discussed again.

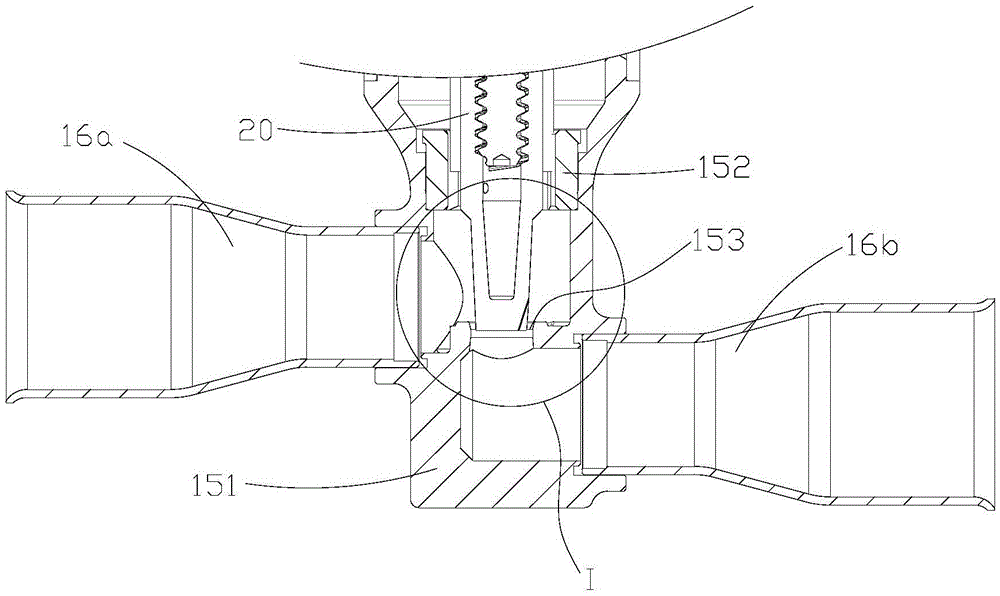

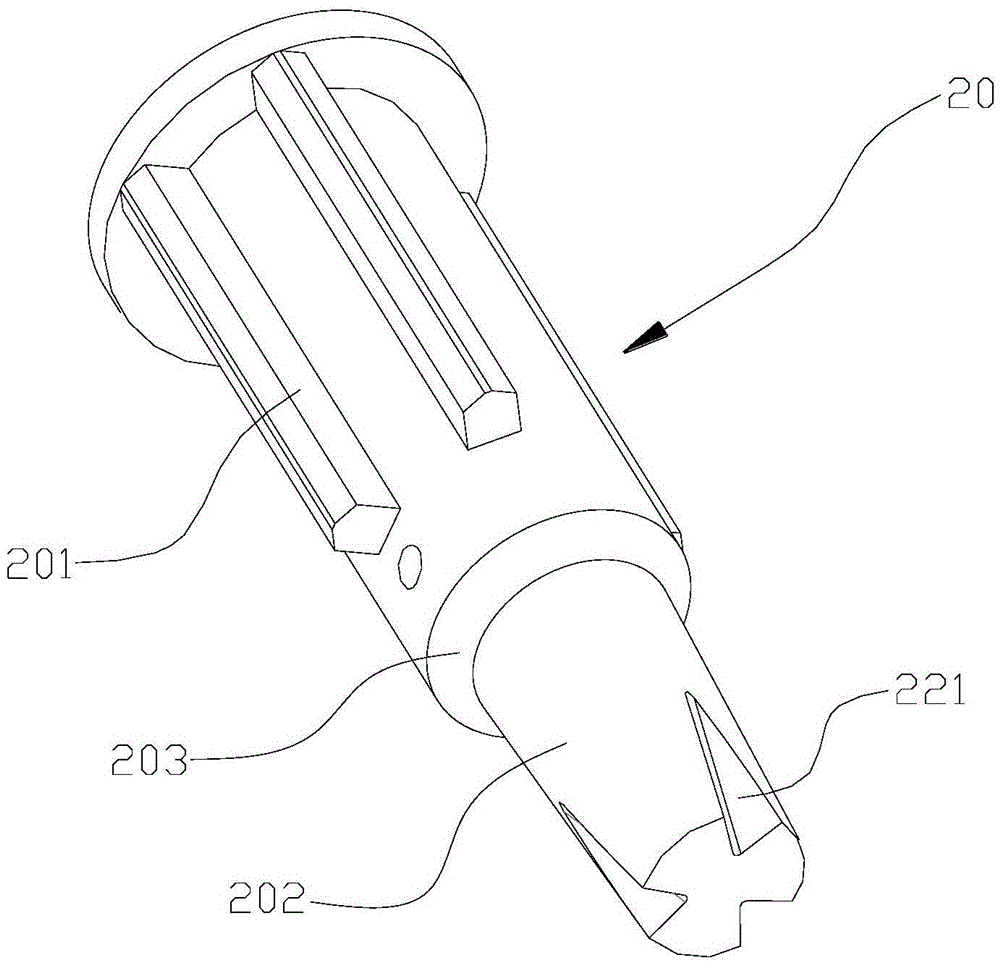

[0043] In this embodiment, the structure of the electronic expansion valve can refer to figure 1 and figure 2 It is understood that the electronic expansion valve includes a driving part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com