Air-leakage-preventing bearing sealing structure for automobile engine

A technology for automotive engine and bearing sealing, applied to shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems of increasing bearing friction resistance, increasing material cost, reducing bearing life, etc., and achieves simplified bearing sealing structure, materials and The effect of low processing cost and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

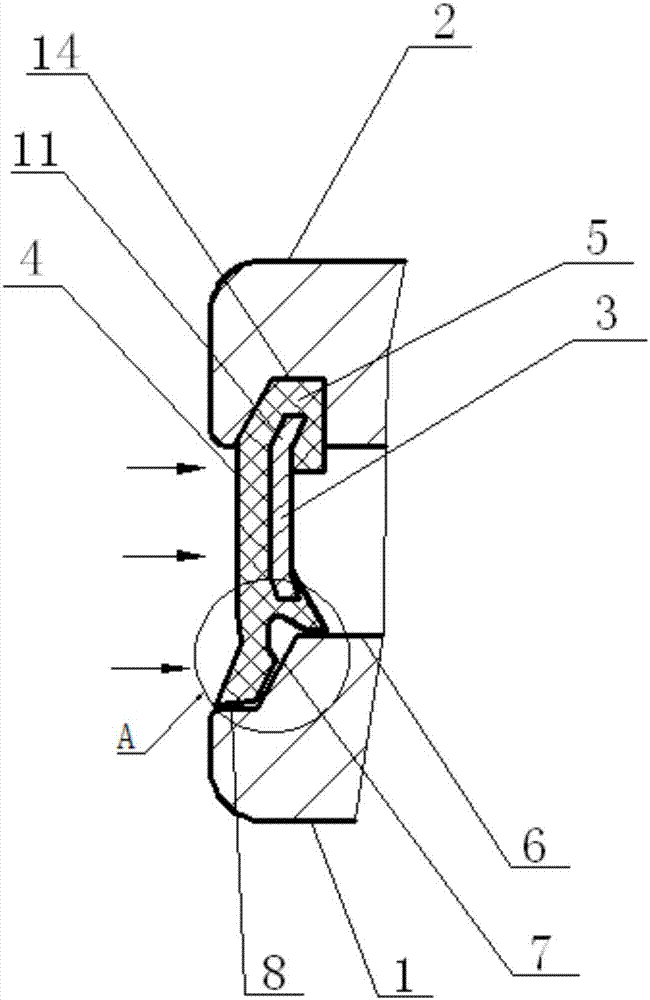

[0027] During installation, first make the sealing inner lip 9 with the second sub-bracket 12 conflict with the inner step 6, and make one side of the sealing outer lip 10 with the third sub-bracket 13 conflict with the outer step 8, and the other side with the slope 7 Compression fit; then through the elastic extrusion deformation of the second sub-bracket 12 and the third sub-bracket 13, the installation part 5 is embedded in the groove 14 of the outer ring to realize the installation of the seal and the bearing ring.

[0028] In this way, when the grease in the bearing groove flows out, the leakage of the grease can be effectively prevented by sealing the inner lip 9; and when the air flow axially presses the upper part of the seal, because the upper part of the seal is in close contact with the groove 14 of the outer ring, effectively Prevent the airflow from entering the bearing; when the airflow axially presses the part A of the seal, since the outer lip 10 of the seal is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com