Hydraulic servo synchronization system

A synchronous system and hydraulic servo technology, applied in the field of electromechanical hydraulics, can solve problems such as the inability to achieve synchronization accuracy, and achieve the effects of accurate calculation, fast response, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

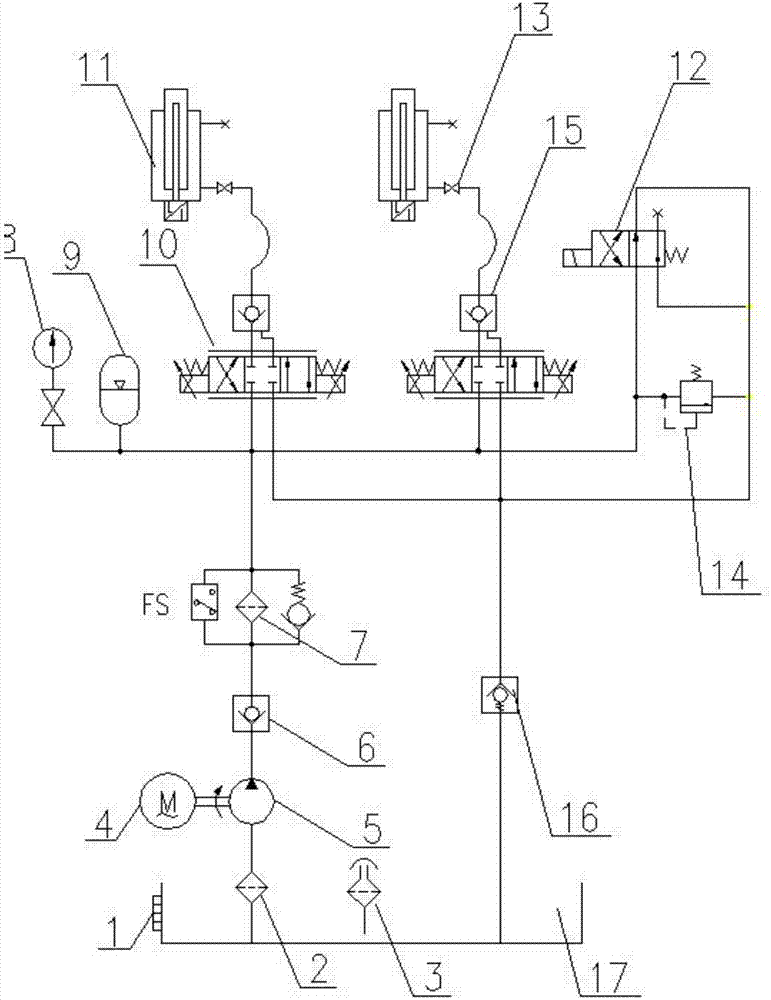

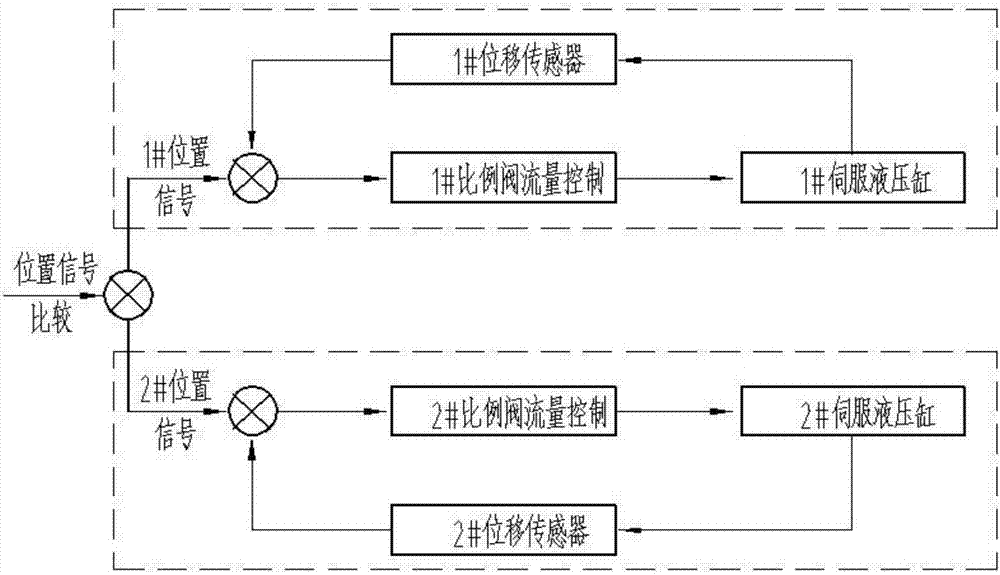

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0036] like figure 1 As shown, a hydraulic servo synchronization system includes: an oil tank 17 for storing oil;

[0037] Auxiliary units with auxiliary oil passages for delivering oil; and

[0038] There is a main unit with a first oil passage, a second oil passage and a reversing valve 12 used for reversing in parallel, and the first oil passage, the second oil passage and the reversing valve 12 are all connected with Auxiliary oil circuit connection.

[0039] In one embodiment of the present invention, the fuel tank 17 adopts a closed fuel tank 17, and a liquid level gauge 1 and an air filter 3 are installed in the fuel tank 17. The fuel tank 17 adopts a closed fuel tank 17, and the air filter 3 is used to mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com