A multifunctional glass shaping device

A glass cup, multi-functional technology, applied in glass forming, glass re-forming, glass manufacturing equipment and other directions, can solve the problems of excessive heating of raw materials, scrapping of raw materials, difficult processing, high defective rate, and achieve low plant investment cost, The effect of fast mechanical operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

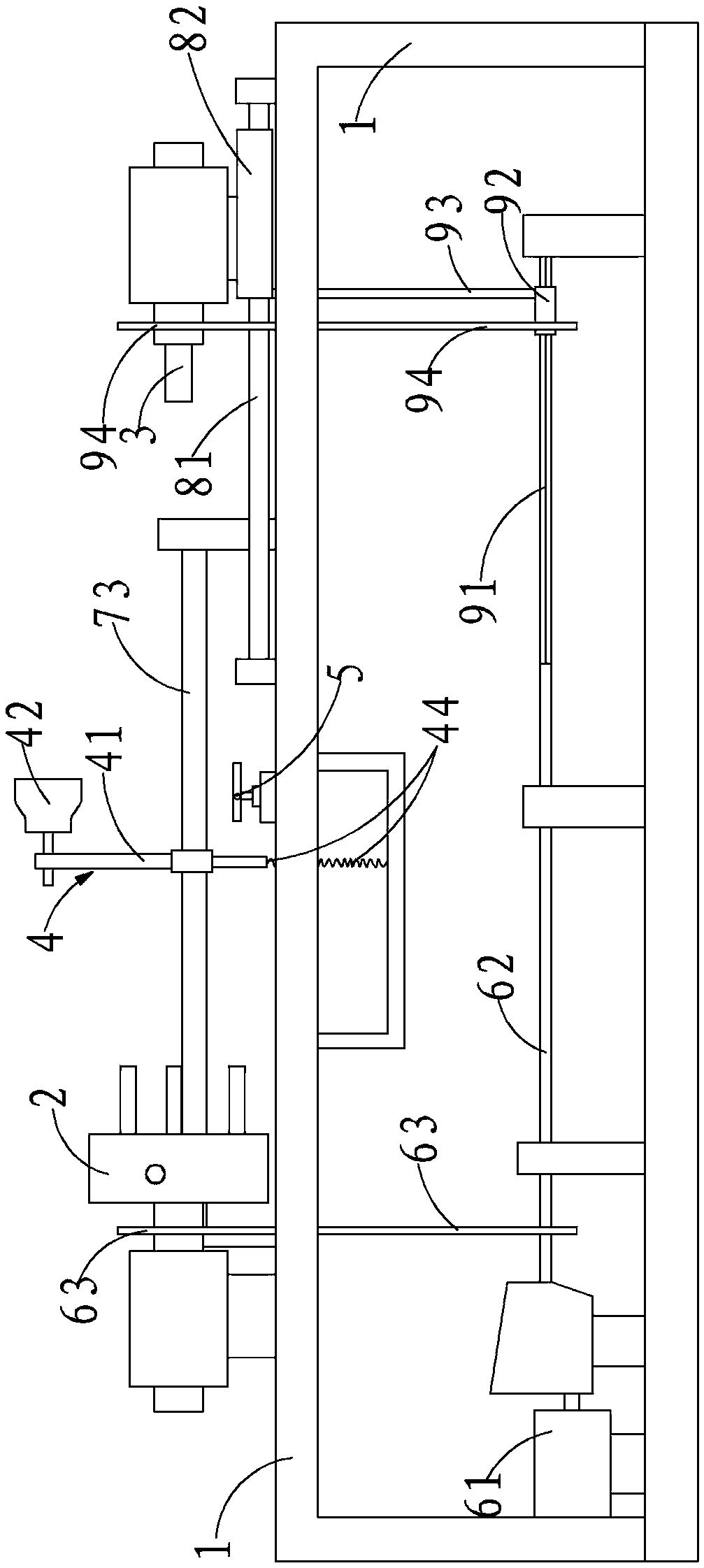

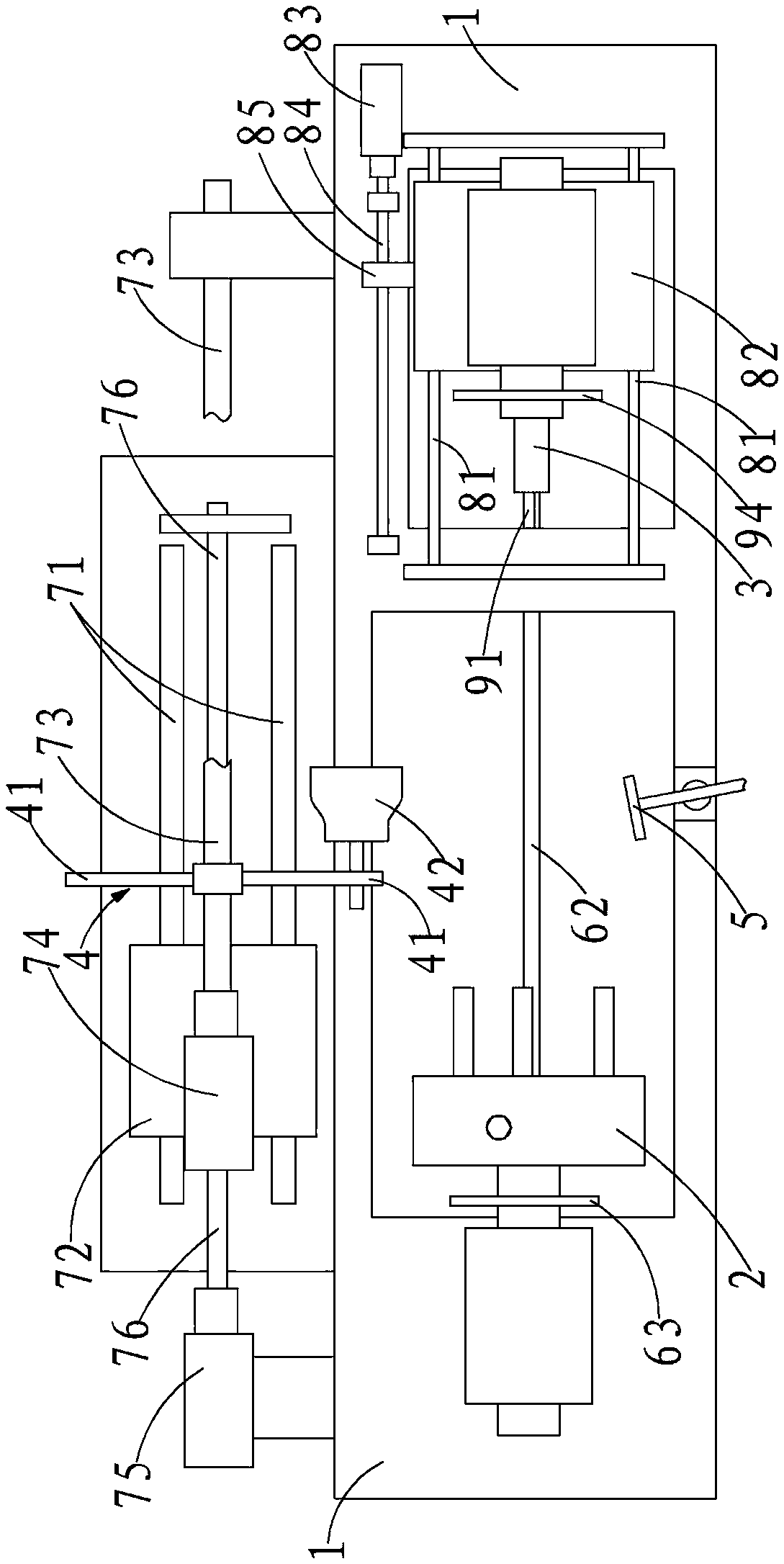

[0023] The following is attached figure 1 , 2 The present invention is further described in detail.

[0024] as attached figure 1 , 2 As shown, a multi-functional glass shaping device includes a frame 1, an active chuck 2 arranged at one end of the frame 1 to clamp and drive the glass to rotate, and an active chuck 2 arranged at one side of the frame 1 for lowering the glass. The profiling arm 4 of the press-shaped glass; the active chuck 2 is connected with the active power system; the profiling arm 4 is arranged on the frame 1 through the profiling mechanism, and the frame 1 is also provided with a The heating nozzle 5 for heating the glass, the heating nozzle 5 corresponds to the position of the action end of the profiling arm 4 after pressing down; the active chuck 2 is arranged on the frame 1 through a bearing. The active chuck 2 is a three-jaw chuck.

[0025] The main power system includes a driving motor 61 and a driving power shaft 62 connected with the power outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com