Cutting device for producing glass cup body

A technology of cutting device and glass cup, applied in glass forming, glass re-forming, glass manufacturing equipment and other directions, can solve the problems of excessive heating, high defective rate, scrapping of raw materials, etc., and achieve the cost of plant investment. The effect of low cost, low cost and standard operation action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

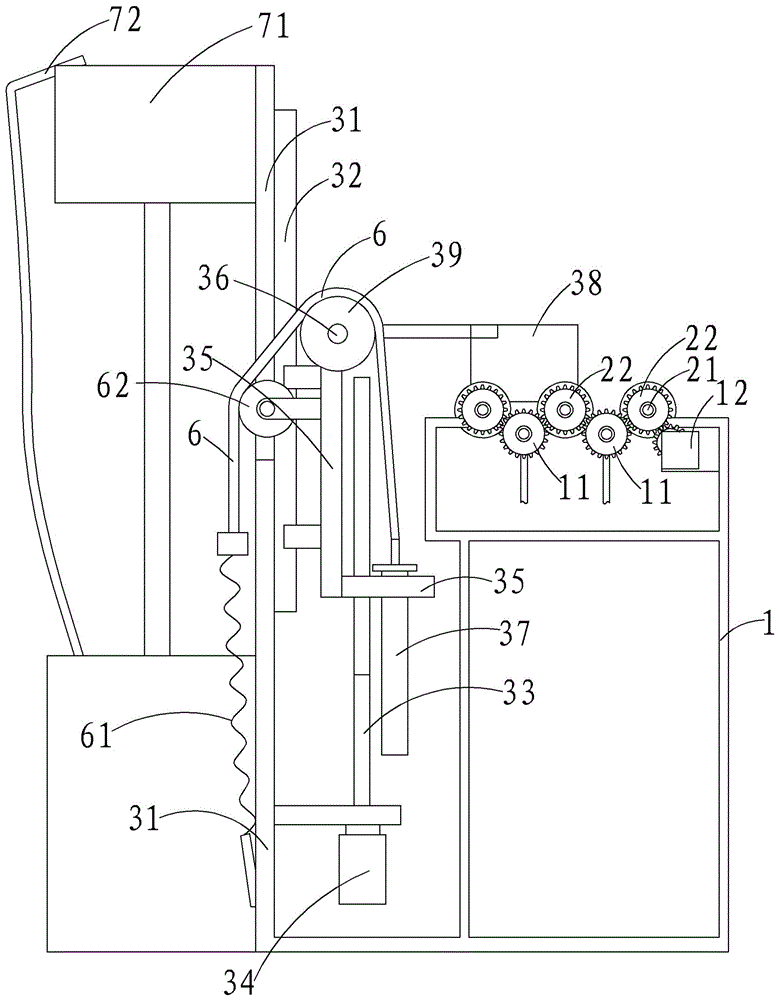

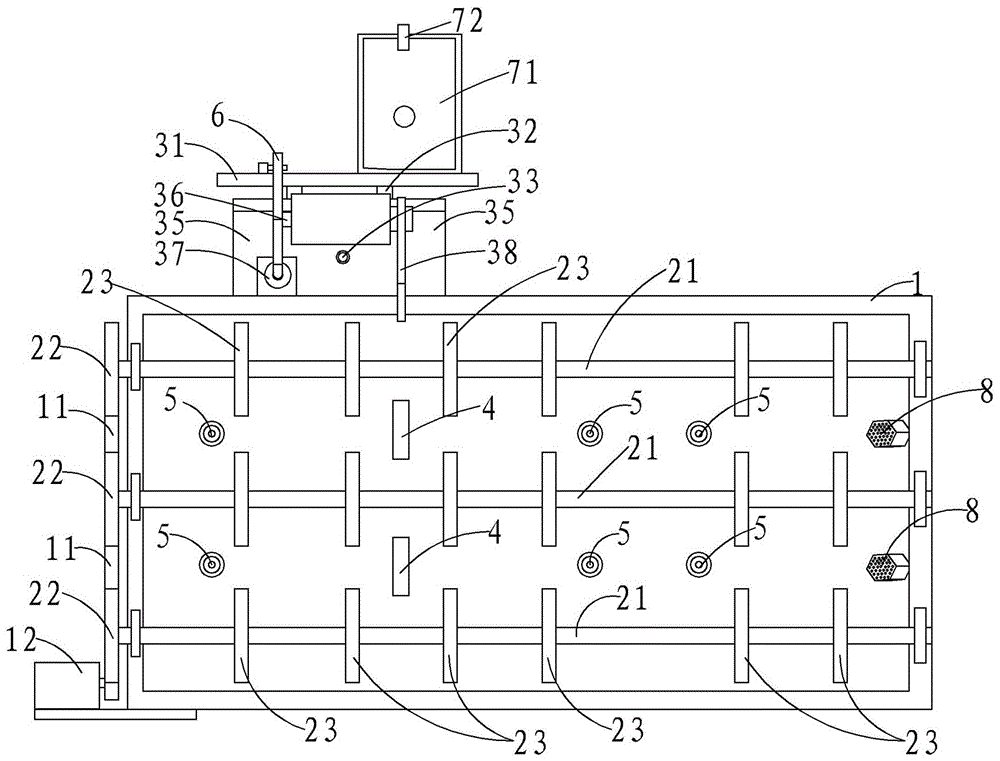

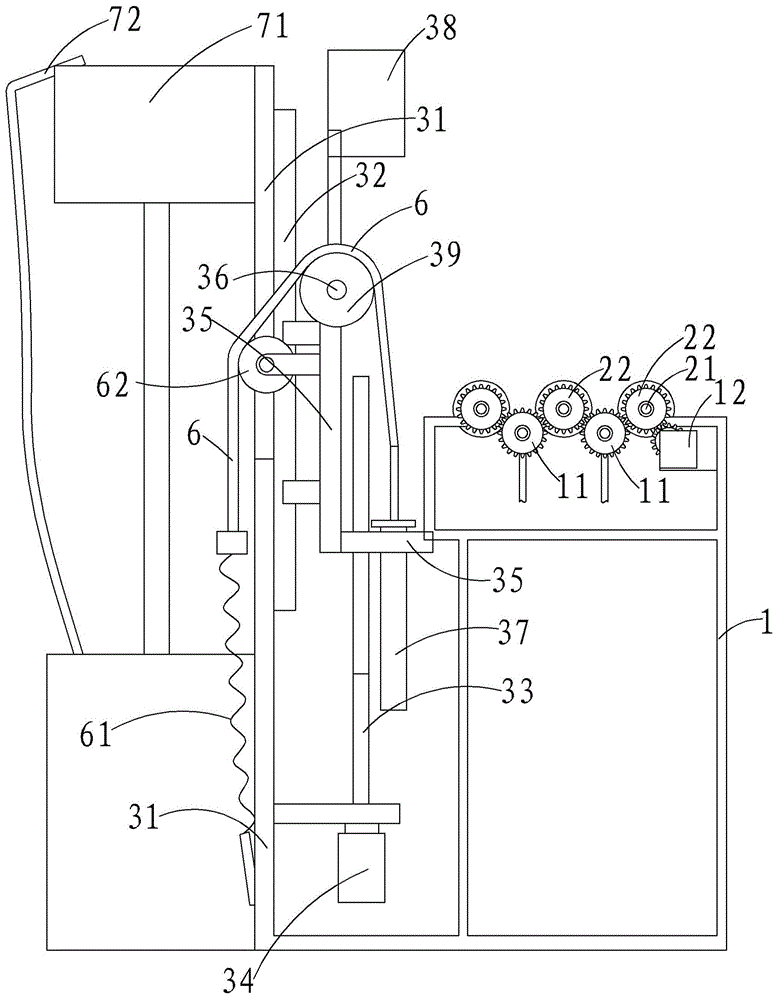

[0022] The following is attached Figure 1-4 The present invention will be described in further detail.

[0023] As attached figure 1 , 2 As shown, a cutting device for producing glass cups includes a frame 1, an idler device arranged on the front side of the frame 1, and a cutting mechanism arranged on the rear side; the idler device includes more than three parallel arranged The supporting roller 21 on the frame 1, the driving gear 22 provided at one end of the supporting roller 21, and the power device for driving the driving gear 22, the supporting roller 21 is uniformly provided with supporting sheets 23; the adjacent supporting roller 21 The direction of rotation is the same; the cutting mechanism includes a vertical back plate 31, an under-cutting mechanism arranged on the back plate 31 through a vertical guide 32, a lead screw 33 is arranged between the bottom of the under-cutting mechanism and the back plate 31, the One end of the lead screw 33 is threadedly connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com