A method for fixed-point and high-efficiency extraction of coalbed methane in goaf

A technology for coalbed methane and goaf, which is applied to mining equipment, mining fluids, and earthwork drilling, etc., can solve the problems of unstable extraction effect and difficulty in determining the extraction horizon, so as to avoid waste of resources and cost-effectiveness. Good, improve the effect of extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

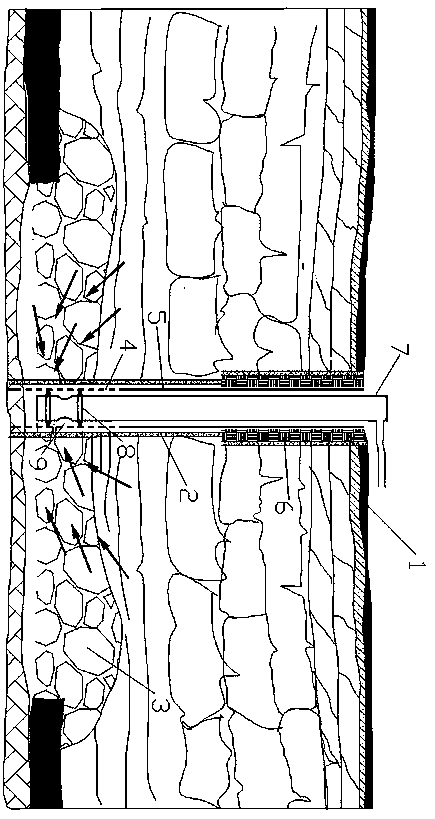

[0016] Below in conjunction with accompanying drawing, the example of the present invention is further described:

[0017] a. From the ground (1) vertically drill the well (2) to the bottom of the goaf (3), and insert the casing (5) with the screen holes (4) at a distance of 20~30cm into the well (2). To the bottom of the goaf (3), and the upper part of the drilling (2) is sealed with cement mortar (6).

[0018] b. Install two "O"-shaped sealing rings (8) with a distance of 1~2m at the lower part of the drainage pipe (7), and install the drainage pipe (7) between the two "O"-shaped sealing rings (8). ) The upper opening diameter is a circular hole (9) of 5-10 mm.

[0019] c. Insert the drainage pipe (7) into the casing (5) to the bottom of the goaf (3), and then the A through air chamber is formed. The coalbed methane that enters the goaf (3) in the extraction pipe (7) through the screen hole (4) of the casing (5) is extracted from the extraction pipe (7).

[0020] d. Move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com