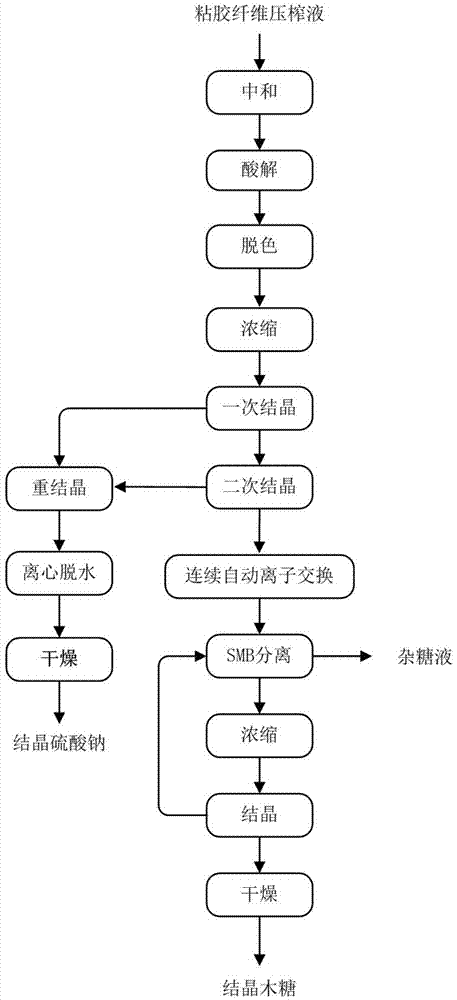

Method for preparation of xylose and co-production of sodium sulfate by employing viscose fiber squeeze liquid as raw material

A viscose fiber and squeezing liquid technology, applied in xylose production, sodium sulfate recovery, sugar production, etc., can solve the problems of large power consumption, secondary pollution, large amount of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Take the viscose fiber squeeze liquid, the alkali mass percentage concentration in the solution is 12%, the hemicellulose mass percentage concentration is 10%, the refractive concentration is 31%, and the conductivity is 500000~800000 μs / cm, dilute the squeeze liquid with pure water to the refractive index Concentration of 18.0%, while stirring, add sulfuric acid solution with a volume concentration of 50% for neutralization, adjust to pH=7.0±0.1, the solution changes from brownish yellow to milky yellow or milky white, and a neutralizing solution is obtained. Add pure water to dilute the neutralizing solution to a refractive concentration of 8.0±1%, then add a sulfuric acid solution with a volume concentration of 50% while stirring, adjust to pH=0.8, and react with acid for 3 hours at 120°C, and the solution turns brownish-yellow to half Transparent liquid with good fluidity. Add 1% powdered activated carbon by dry matter weight, stir and decolorize at 75°C for 1 hour,...

Embodiment 2

[0064] The reaction solution obtained in Example 1 contains a high concentration of sodium sulfate, and the conductivity is 550000 μs / cm. The reaction solution obtained in Example 1 is evaporated and concentrated to a concentration of 30.0~40.0% by mass, cooled to below 10°C, and crystallized by cooling. Centrifuge dehydration separation to obtain primary crystalline sodium sulfate crude product and primary crystallization mother liquor.

[0065] The conductivity of primary crystallization mother liquor is 100000~120000 μs / cm. The primary crystallization mother liquor still contains a large amount of sodium sulfate.

[0066] Evaporate and concentrate the primary crystallization mother liquor to a mass percent concentration of 40.0±5.0%, lower the temperature to below 10°C, cool and crystallize, and centrifuge to obtain the secondary crystallization sodium sulfate crude product and the secondary crystallization mother liquor. The conductivity of the secondary crystallization m...

Embodiment 3

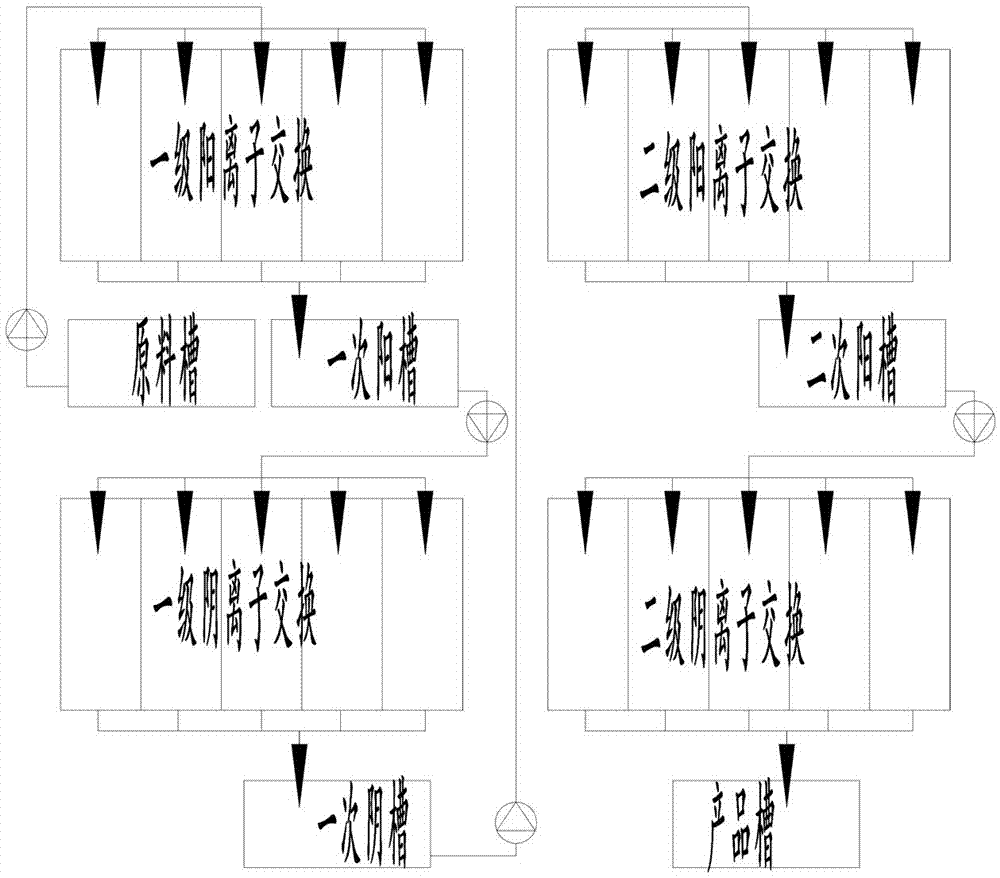

[0069] The secondary crystallization mother liquor obtained in Example 1 was deionized by continuous automatic ion exchange method.

[0070] The device and operation process adopted by the continuous automatic ion exchange method will be further described below in conjunction with the accompanying drawings.

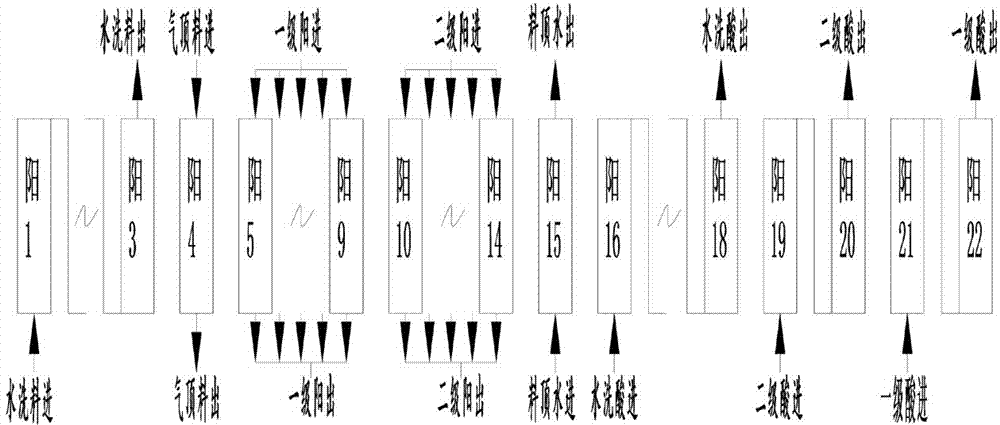

[0071] The continuous automatic ion exchange device adopted in the present invention adopts a group of 22 cation resin columns and a group of 22 anion resin columns. The resin columns are formed in series, and the upper part of the previous resin column is connected with the lower part of the subsequent resin column through pipelines and connecting valves.

[0072] In the continuous automatic ion exchange device adopted in the present invention, the cation exchange operates periodically and automatically, and one cycle is composed of 22 processes, that is, process 1 to process 22, which is repeated; the anion exchange is periodically operated automatically, and one cycle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com