Titanium dioxide nanowire/two-dimensional layered titanium carbide composite material and low-temperature preparation method thereof

A two-dimensional layered, titanium dioxide technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, nanotechnology, etc., can solve the problem of disordered arrangement of titanium oxide, achieve improved electrochemical performance, novel shape, and preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

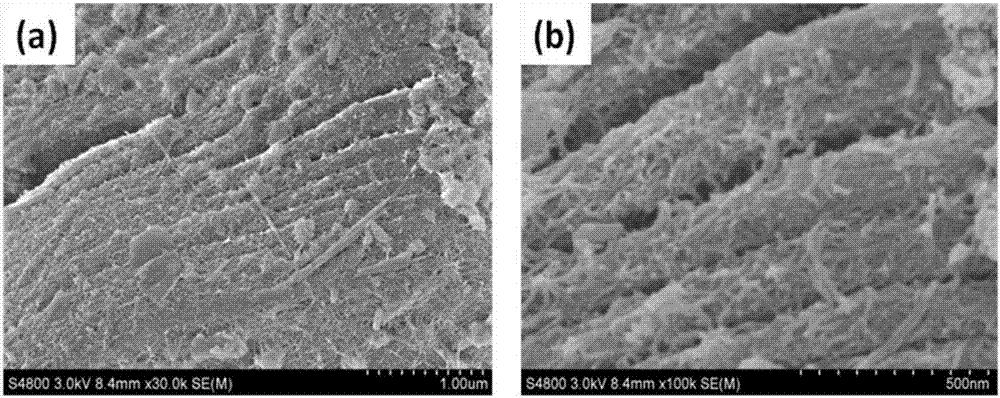

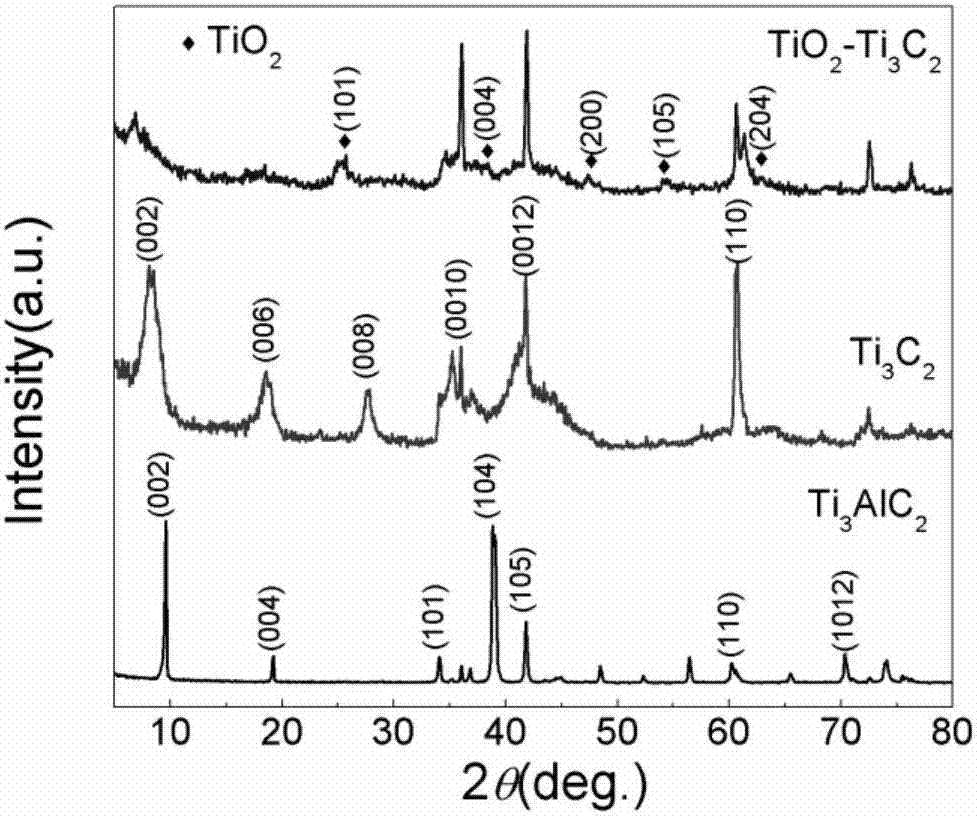

[0029] Take Ti 3 C 2 Dissolve 50 mg of the powder in 20 mL of potassium hydroxide solution with a concentration of 1 mol / L and stir at 40 ° C for 3 h. Then, the reaction mixed solution was centrifuged and washed several times with deionized water and absolute ethanol, and then the solid was separated by centrifugation, and vacuum-dried at 40° C. for 30 hours to obtain a titanium dioxide nanowire / two-dimensional layered titanium carbide nanocomposite material.

Embodiment 2

[0031] Take Ti 3 C 2 Dissolve 200 mg of the powder in 20 mL of potassium hydroxide solution with a concentration of 3 mol / L and stir at 35 °C for 0.5 h. Then, the reaction mixed solution was centrifuged and washed several times with deionized water and absolute ethanol, and then the solid was separated by centrifugation, and vacuum-dried at 60° C. for 12 hours to obtain a titanium dioxide nanowire / two-dimensional layered titanium carbide nanocomposite material.

Embodiment 3

[0033] Take Ti 3 C 2 Dissolve 150mg of the powder in 50mL of 8mol / L sodium hydroxide solution and stir at 30°C for 0.5h. Then, the reaction mixed solution was centrifuged and washed several times with deionized water and absolute ethanol, and then the solid was separated by centrifugation, and vacuum-dried at 60° C. for 48 hours to obtain a titanium dioxide nanowire / two-dimensional layered titanium carbide nanocomposite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com